Production process and production system for preparing series of perfumes by hydrogenating citral

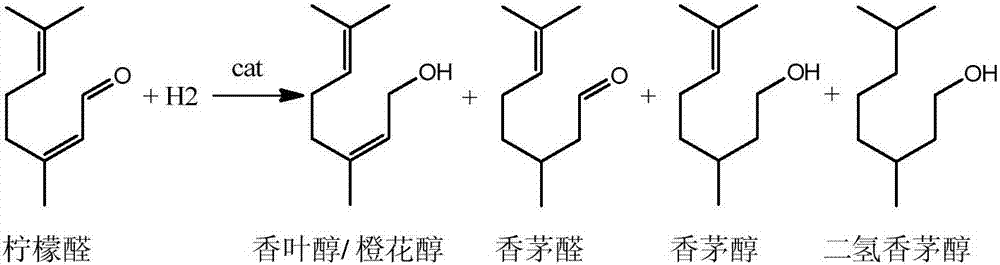

A production process, citral technology, applied in hydrogenation preparation, carbon-based compound preparation, hydroxyl compound preparation, etc., can solve the problems of low reaction selectivity, poor market adaptability, etc., to maximize profits, improve market adaptability, The effect of flexible response to market changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

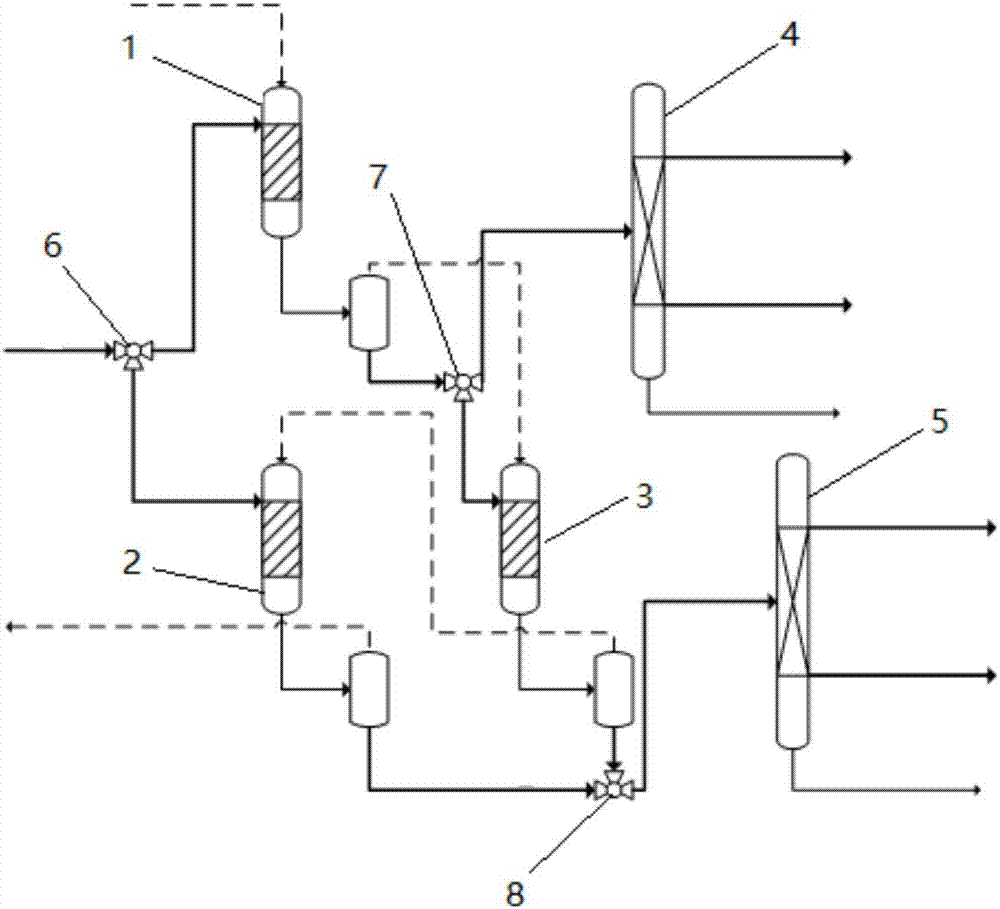

[0037] This example provides a production system for producing a series of spices by hydrogenation of citral. The production system comprises a first reactor 1 and a second reactor 2, wherein the first reactor 1 is an equipment for preparing nerol and geraniol by the hydrogenation reaction of citral, and the second reactor 2 is for the hydrogenation of citral Equipment for preparing citronellal, geraniol and dihydrocitronellol by reaction. It also includes a first regulating valve for adjusting the input amount of citral in the first reactor 1, by adjusting the regulating valve to regulate the input amount of citral in the first reactor 1, thereby controlling its production load. It also includes a second regulating valve for adjusting the input amount of citral to the second reactor 2, by adjusting the regulating valve to adjust the input amount of citral to the second reactor 2, thereby controlling its production load. Preferably, the first regulating valve and the second r...

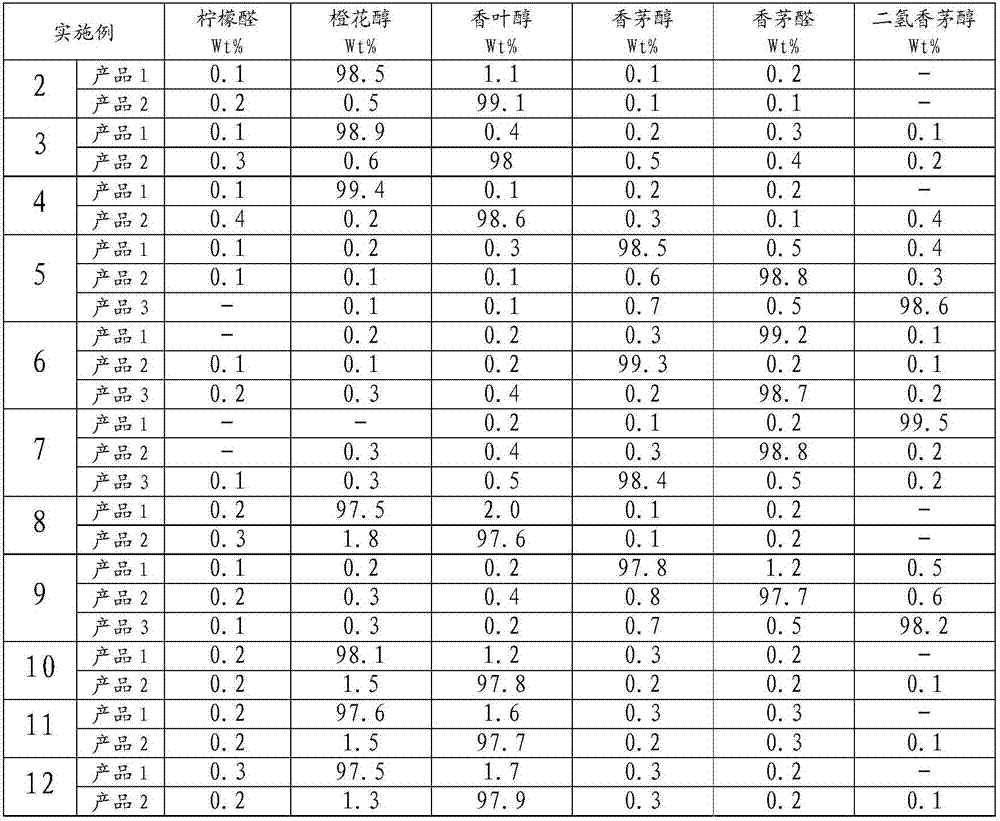

Embodiment 2

[0042] Example 2 is produced using the production system of Example 1.

[0043] Through market research, it is found that the market demand and price of nerol and geraniol are higher than that of citronellal, citronellol and dihydrocitronellol, so the production process of embodiment 2 mainly starts the first reactor 1 in the production system And the first rectifying tower 4.

[0044] The preparation of the catalyst I used in this embodiment comprises the following steps: using activated clay (purchased from Anji Zhongxin Activated Clay Co., Ltd., HT series activated clay) as a carrier, with nickel as an active component, and with P and Zn as catalyst promoters agent, wherein phosphoric acid is used as the phosphorus source, and zinc chloride is used as the zinc source. Dilute phosphoric acid into a 10wt% aqueous solution, impregnate activated clay with phosphoric acid overnight at room temperature, then dry at 80°C for 5 hours, then dissolve nickel chloride and zinc chlorid...

Embodiment 3

[0048] Embodiment 3 is produced using the production system of Embodiment 1.

[0049] Through market research, the market demand and price of nerol and geraniol are higher than citronellal, citronellol and dihydrocitronellol, so the production technology of embodiment 3 mainly uses the first reactor 1 and the first rectification Tower 4.

[0050] Load catalyst I in the first reactor 1,, based on the quality of catalyst I, wherein Ni loading (wt%) is 10.0%, P loading (wt%) is 5.0%, Zn loading (wt%) 5.0% , the carrier of the catalyst I is activated clay (same as Example 2, being HT series activated clay). Catalyst 1 of this embodiment was prepared with reference to the method of Example 2, and will not be repeated.

[0051] The first reactor 1 was operated at 200° C., reaction pressure 5 MPa, and citral flow rate 20 mol / h. The product was analyzed by chromatography, the conversion rate of citral was 96%, and the total selectivity of nerol and geraniol was 97%. The product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com