An absorption cooling and heating air-conditioning system with gas-liquid separation and injection efficiency enhancement and its operation mode

A gas-liquid separation, cooling and heating air-conditioning technology, used in air-conditioning systems, boiler absorbers, adsorption machines, etc., can solve the problems of unacceptable users, low system performance coefficient, poor cooling effect, etc., to increase available energy and improve replacement. Thermal efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

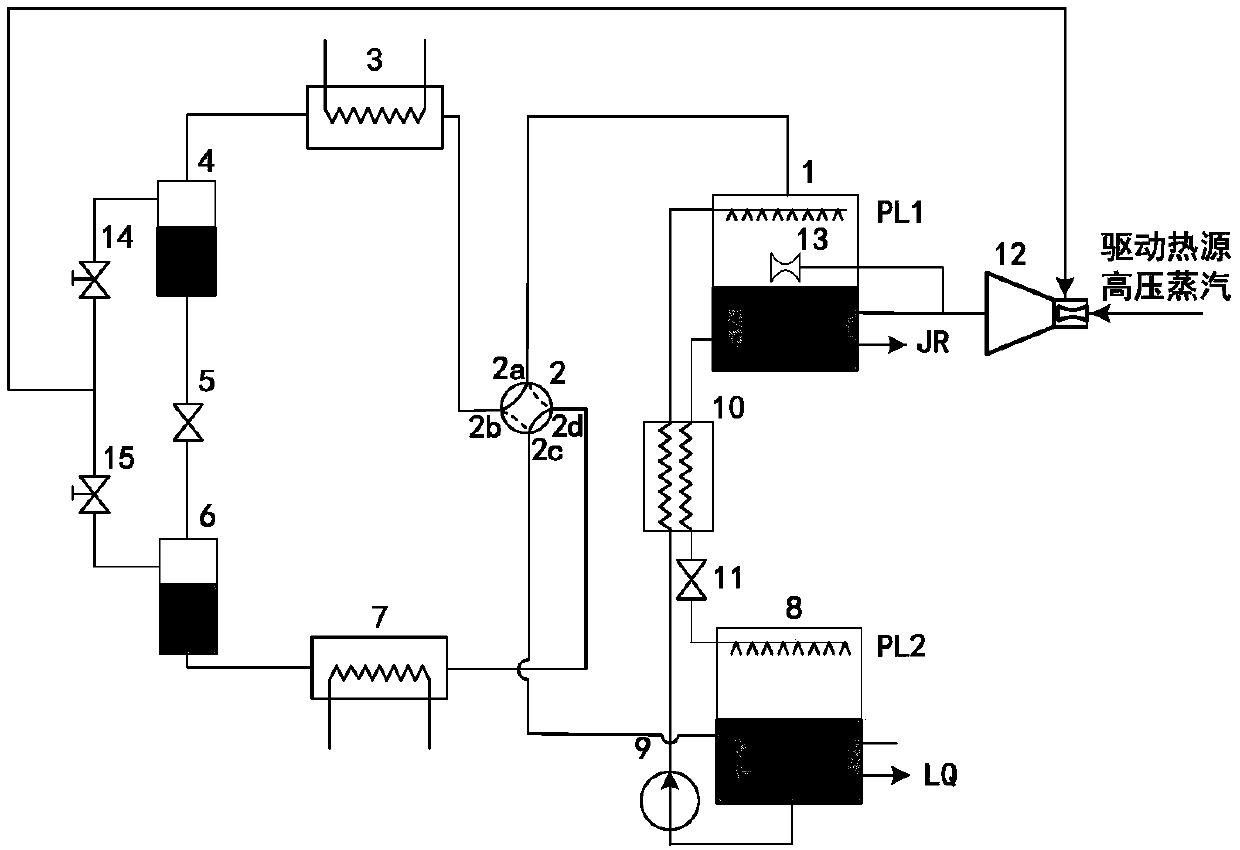

[0022] Such as figure 1 As shown, a gas-liquid separation jet synergistic absorption cooling and heating air-conditioning system of the present invention consists of a generator 1, a four-way reversing valve 2, an indoor coil 3, a first gas-liquid separator 4, a throttle mechanism 5, The second gas-liquid separator 6, the outdoor coil 7, the absorber 8, the solution pump 9, the solution heat exchanger 10, the solution valve 11, the steam ejector 12, the supersonic nozzle 13, the first control valve 14 and the second control The upper part of the generator 1 is provided with a first spray pipe PL1, the middle part is provided with a supersonic nozzle 13, and the lower part is provided with a heating pipe JR; the upper part of the absorber 8 is provided with a second spray pipe PL2, The lower part is equipped with cooling water pipe LQ;

[0023] The upper outlet of the generator 1 is connected to the first valve port 2a of the four-way reversing valve 2, one end of the indoor coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com