High-voltage cable metal outer sheath grounding loop current on-line monitoring system

A grounding circulation, high-voltage cable technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as increasing line operating loss, increasing cable temperature, and stopping power supply, saving manpower, reducing the number of power outages, and improving work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

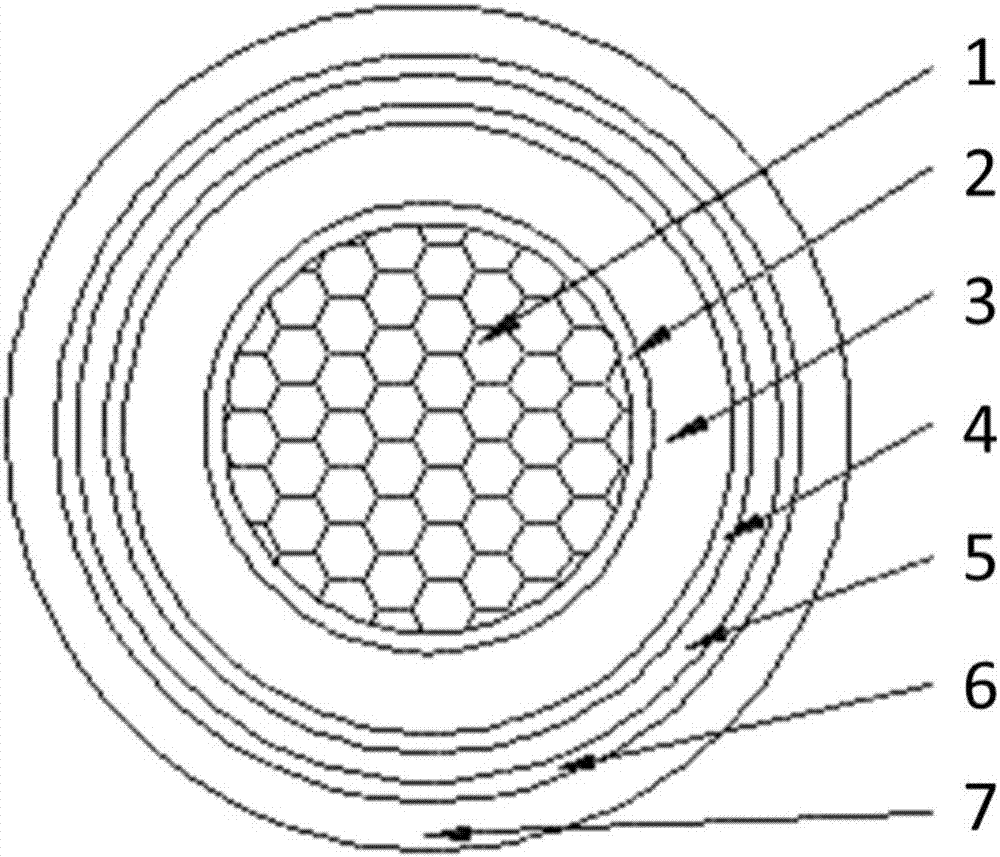

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The on-line monitoring system (system) for grounding circulation of the metal outer sheath of a high-voltage cable of the present invention is used for real-time testing of the performance of XLPE cables. Such as figure 1 As shown, the cable core 1 of the XLPE XLPE cable is a tightly pressed copper or aluminum conductor, and the outside of the cable core 1 is sequentially covered with a conductor shielding layer 2, an XLPE insulating layer 3, an insulating shielding layer 4, and a longitudinal water-blocking layer. Buffer layer 5, corrugated aluminum sheath 6 and polyvinyl chloride or polyethylene sheath 7.

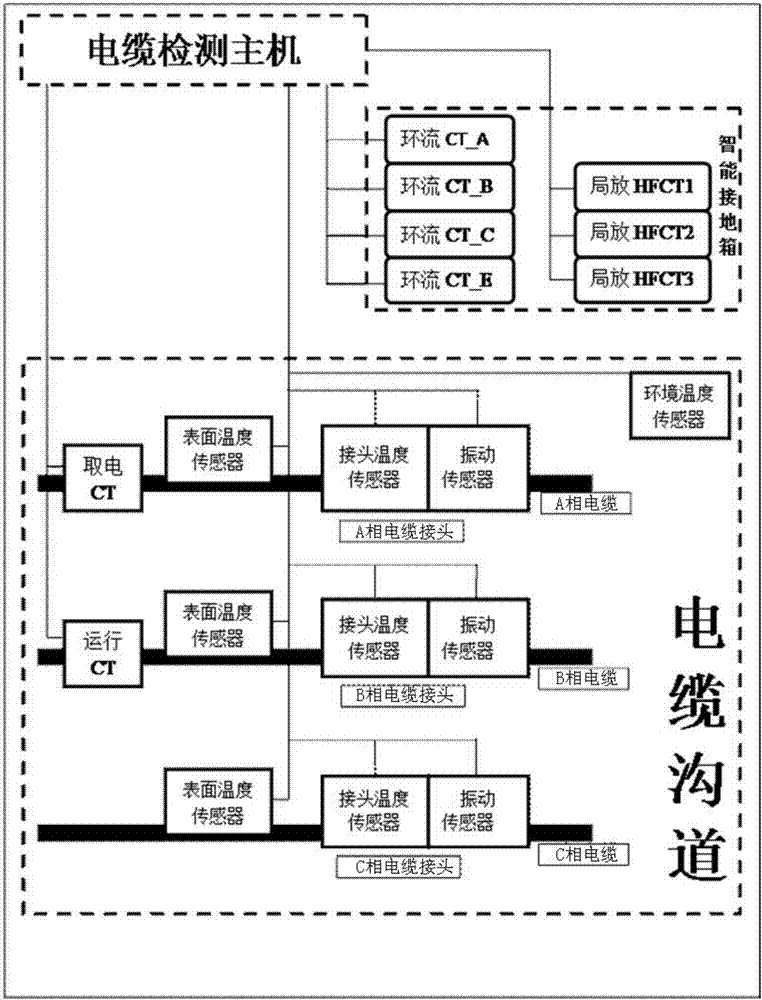

[0033] The system of the present invention is provided with a front-end remote terminal unit RTU, an integrated monitoring center server (server) and a user mobile phone, and adopts GSM, code division multiple access between the front-end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com