Radiation-resistant and bending-resistant reinforced optical cable

A radiation-resistant and reinforced technology, applied in the directions of light guides, optics, optical components, etc., can solve the problem that the optical cable is difficult to meet, and achieve the effect of light traction, excellent flame retardant performance, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

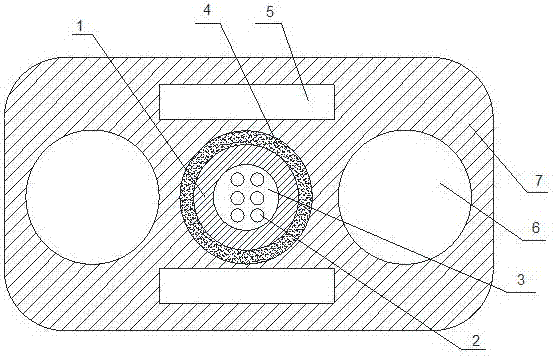

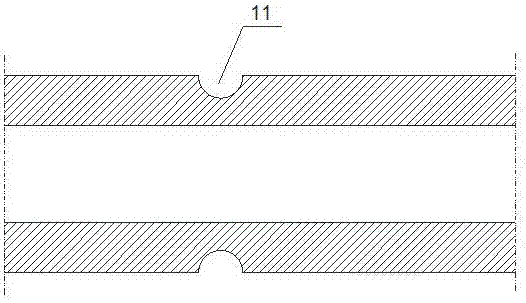

[0023] Such as figure 1 and figure 2 As shown, a radiation-resistant and lightning-proof reinforced optical cable includes a cable core, an armor layer and an outer sheath 7, and the cable core includes a loose tube 1, an even number of quartz optical fibers 2 coated with a radiation-resistant coating and fiber paste 3. The optical fiber 2 is set in the loose tube, and the fiber paste 3 is filled in the gap between the optical fiber and the loose tube. The loose tube is made of radiation-resistant and flame-retardant polytetrafluoroethylene. Due to the loose tube structure, the optical fiber is in a relaxed state in the loose tube, which can obtain effective and reasonable excess length and has good optical and mechanical properties. , At the same time, it can effectively shield the damage of radiation to the optical fiber and has the effect of flame retardancy. The outer wall of the loose tube 1 is provided with annular grooves 11 at equal intervals along the length direct...

Embodiment 2

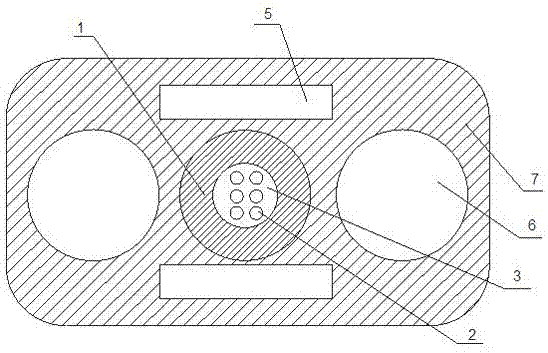

[0031] Such as figure 2 and image 3As shown, a radiation-resistant and lightning-proof reinforced optical cable includes a cable core, an armor layer and an outer sheath 7, and the cable core includes a loose tube 1, an even number of quartz optical fibers 2 coated with a radiation-resistant coating and fiber paste 3. The optical fiber 2 is set in the loose tube, and the fiber paste 3 is filled in the gap between the optical fiber and the loose tube. The loose tube is a PBT loose tube. Due to the loose tube structure, the optical fiber is in a relaxed state in the loose tube, and an effective and reasonable excess length can be obtained. It has good optical and mechanical properties. A non-metallic armor layer is set on the outside of the casing to further enhance the mechanical properties of the cable core, which has strong impact resistance against external forces and is not easily damaged. The outer wall of the loose tube 1 is provided with annular grooves 11 at equal i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap