Automatic transverse pot seedling transplanting device

A horizontal and pot seedling technology, applied in the field of agricultural machinery, can solve problems such as low degree of automation, insufficient degree of chemical control, complex structure, etc., to ensure flexibility and stability, realize precision controllability, and improve transplanting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

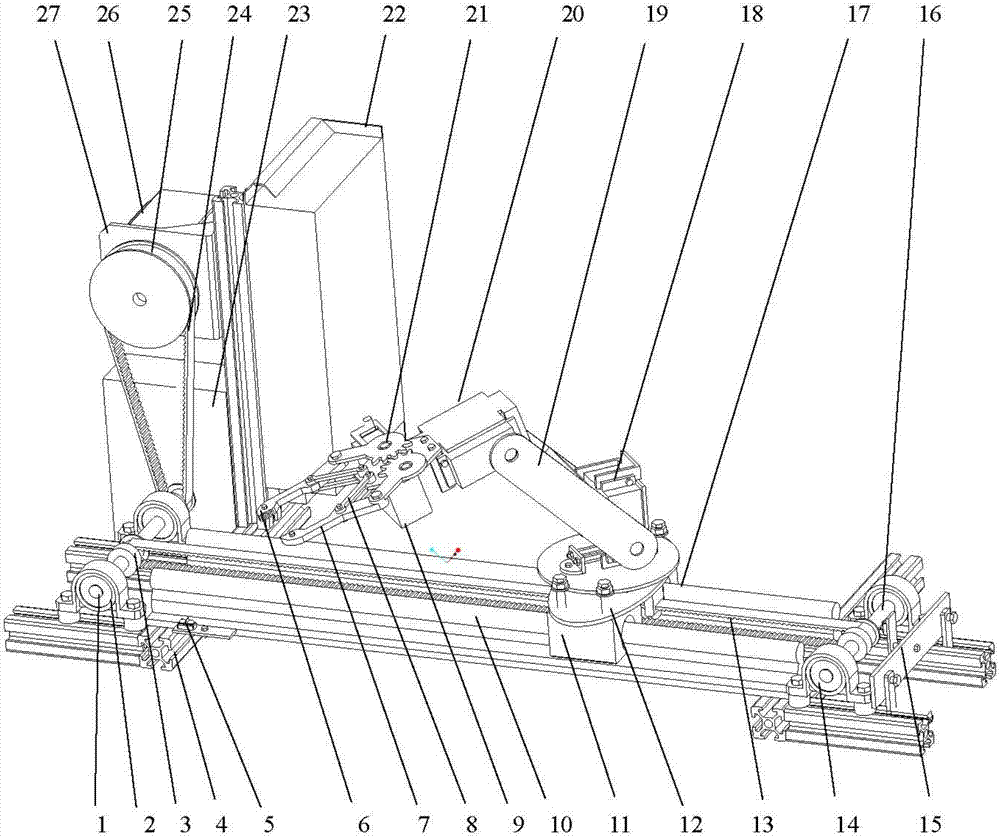

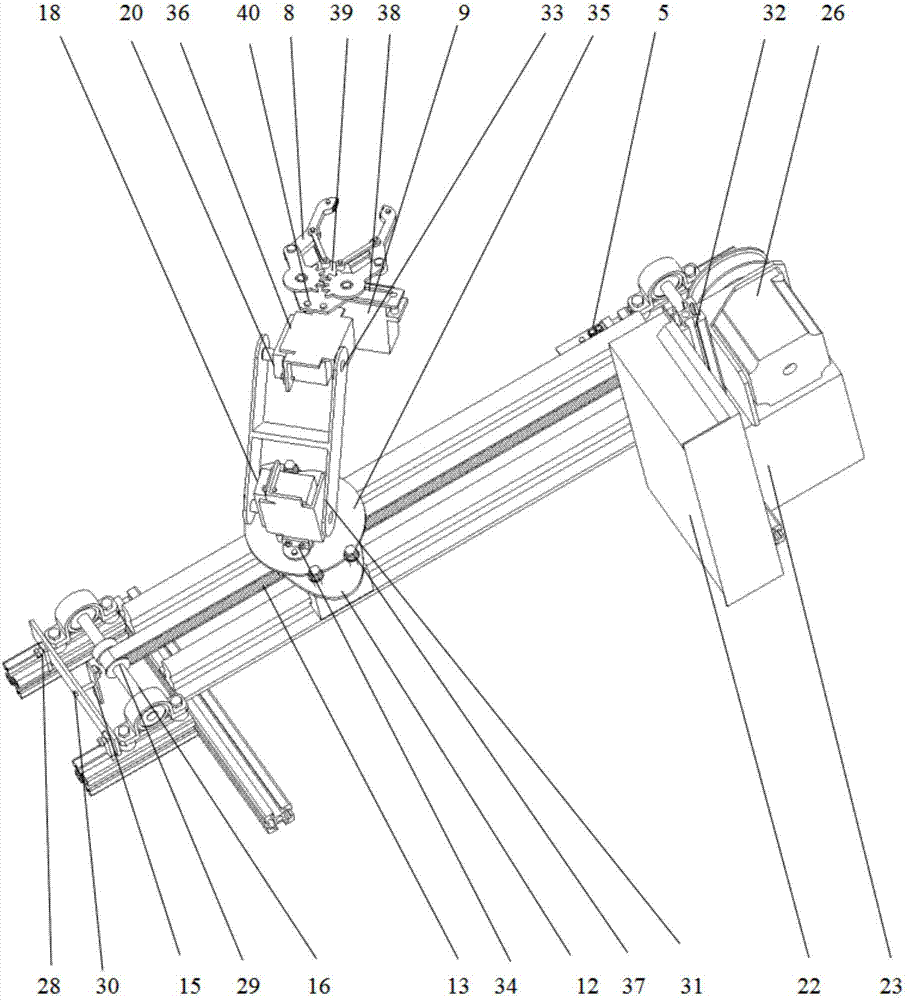

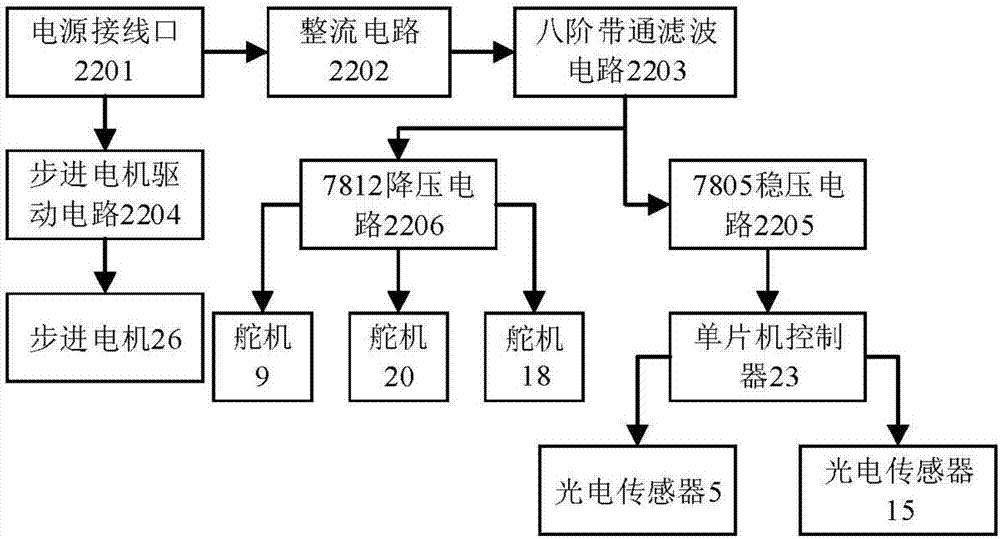

[0023] Such as Figure 1~2 Shown, a kind of automatic lateral transplanting pot seedling device, it comprises, power input shaft 1, first synchronous wheel 3, bottom bracket 4, first photoelectric sensor 5, mechanical claw arm 7, parallel four bar type mechanical claw 8, The third steering gear 9, the first circular guide rail 10, the transverse sliding table 11, the elliptical disk base 12, the horizontal closed synchronous belt 13, the second photoelectric sensor 15, the transmission shaft 16, the first steering gear 18, the rectangular connecting arm 19, Second steering gear 20, miniature bearing 21, current source power supply system 22, single-chip microcomputer controller 23, deceleration wheel 25 and stepper motor 26, it is characterized in that: described bottom bracket 4 comprises support on the first bearing support 2 and The square aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com