Compressed air system detection table of resistance welding machine

A technology of resistance welding machine and compressed air, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of detection result error, low, human influence factors, etc., and achieve convenient operation and simple wiring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

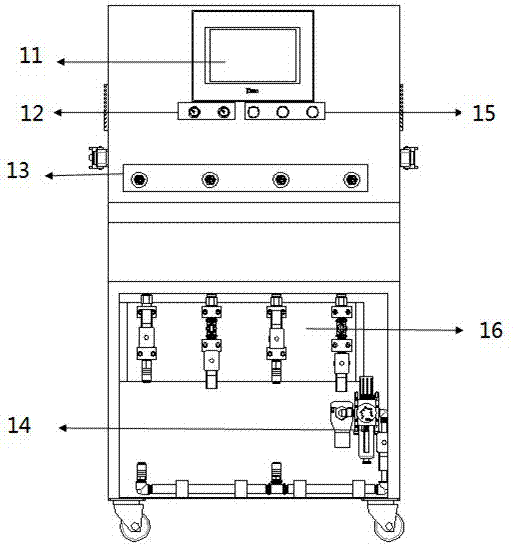

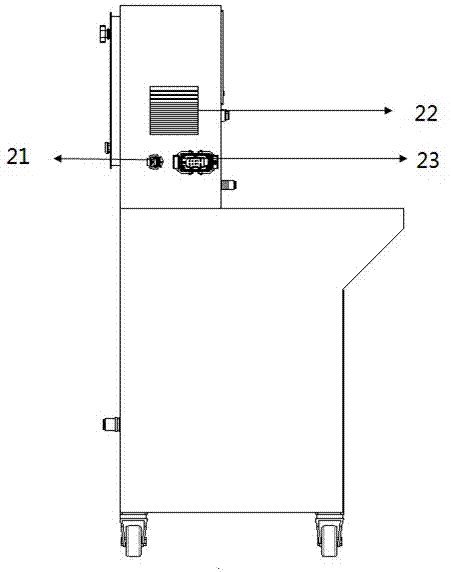

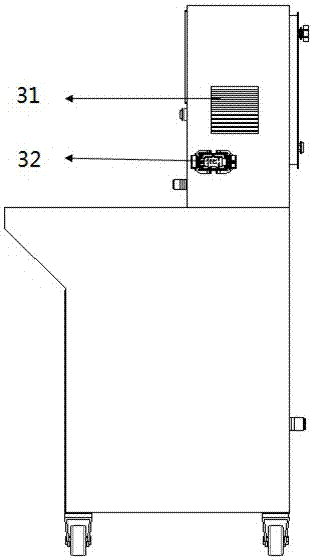

[0029] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0030] Such as figure 1 As shown, the key switch (left): control the 24VDC input power of the power cabinet.

[0031] Key switch 12 (right): 24VDC total working power in the control cabinet.

[0032] Indicator light 15 (left): Indicates the 24VDC input power of the power cabinet.

[0033] Indicator light 15 (right): Indicates the 24VDC working power supply of the cabinet door.

[0034] Touch screen 11: According to different types of equipment to be inspected, its performance is detected through the touch screen control operation.

[0035] Port 13: From left to right, the first and third ports are air intake ports, and the second and fourth ports are return air ports.

[0036] Detection circuit 16: connect the detection module 16 with the device to be detected through a hose.

[0037] Detection module 14: used to complete the whole process of detecting whether the performance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com