A Height Platform Adjustment Device Applied to Assembly of Fuel Main Pipe and Its Application Method

A fuel manifold and adjusting device technology, applied in the field of aviation parts assembly, can solve the problems of hidden dangers in the assembly of the main combustion chamber fuel pipeline, high risk factor of the main combustion chamber casing, low work efficiency, etc., so as to improve the assembly quality, The effect of reducing the difficulty of operation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

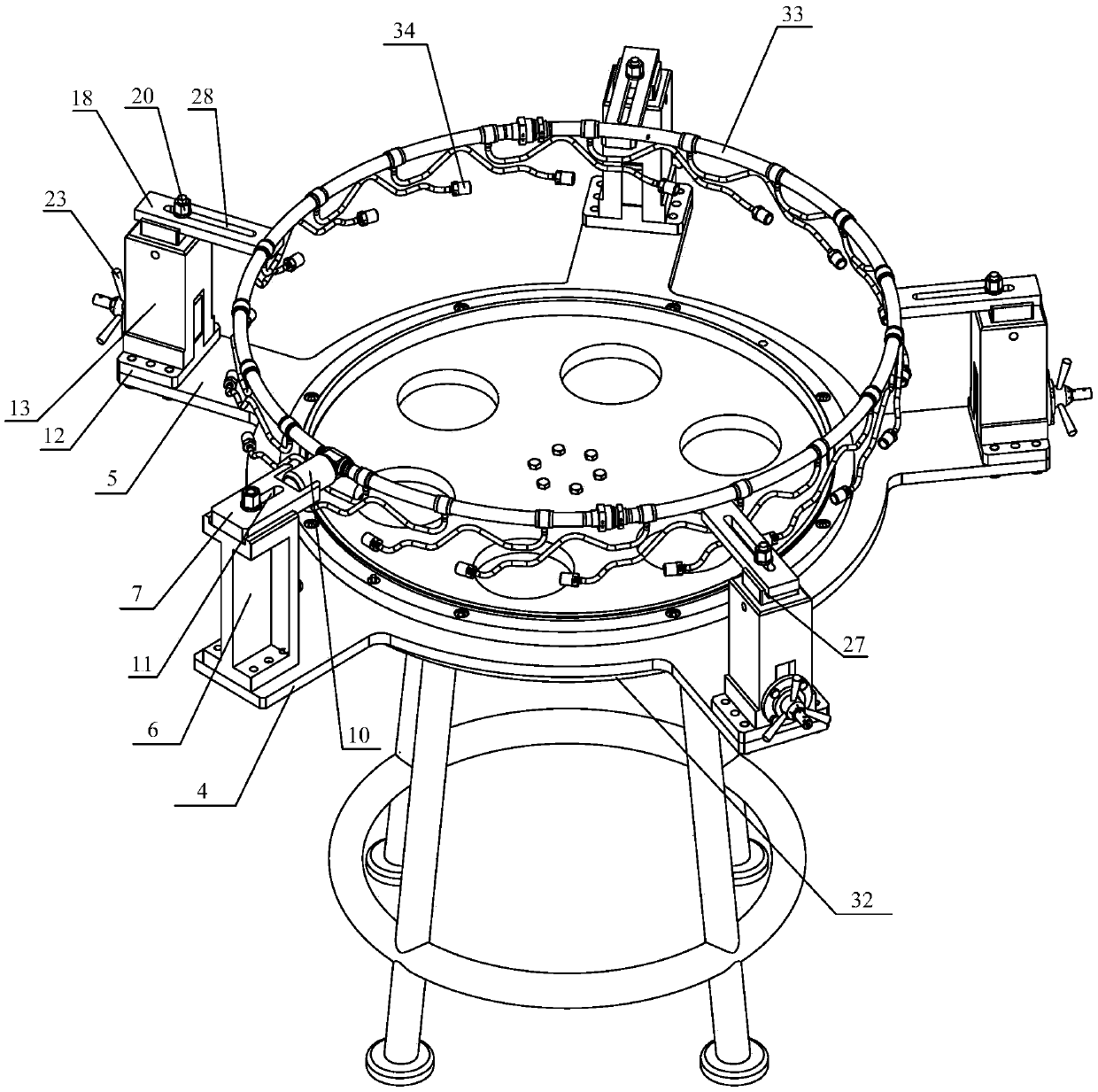

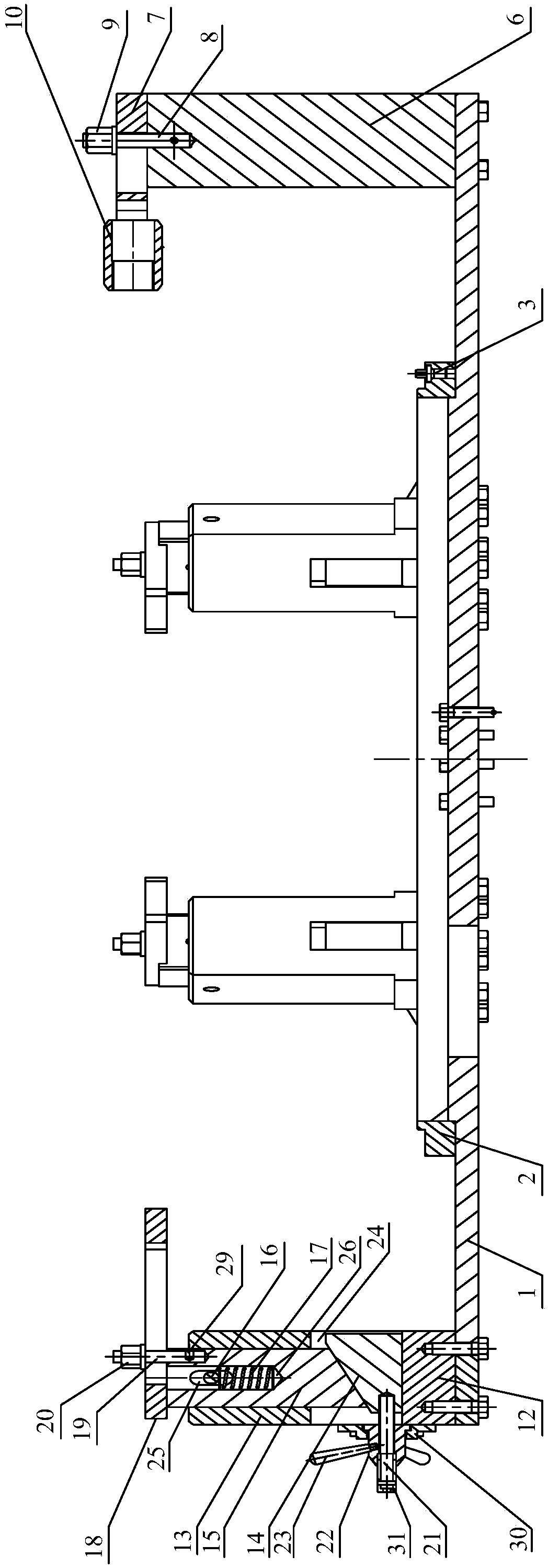

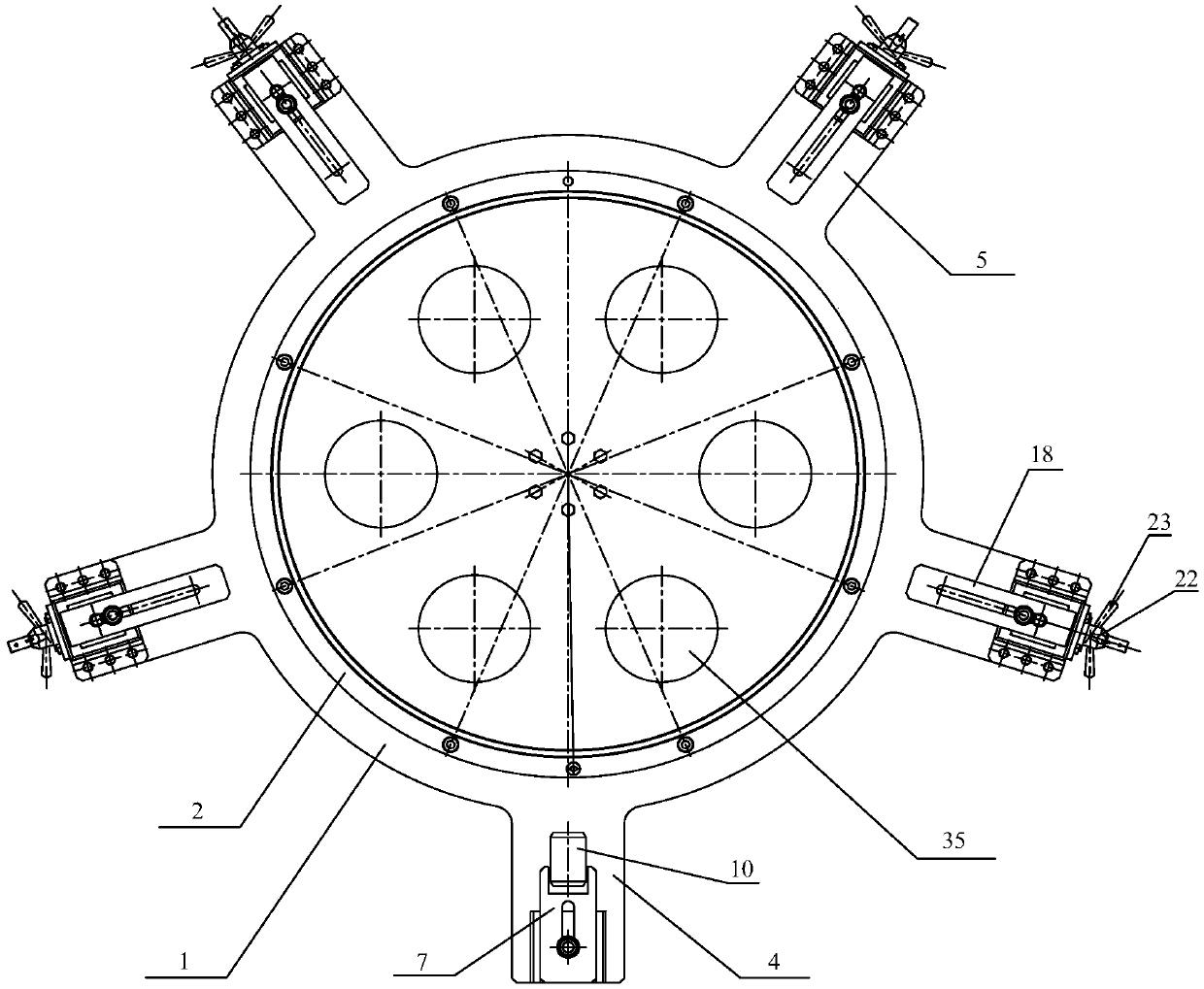

[0025] In order to solve the problems existing in the assembly process of the existing main combustion chamber fuel pipeline, such as Figure 1 to Figure 4 As shown, the present invention provides a height platform adjustment device applied to the assembly of the fuel main pipe. The height platform adjustment device applied to the assembly of the fuel main pipe includes a circular base 1, a positioning ring 2, a positioning pin 3, an angular positioning device and height adjustment device;

[0026] The positioning ring 2 is installed on the circular base 1, and the positioning ring 2 is equipped with a plurality of positioning pins 3 in the circumferential direction. The positioning pins 3 are used for positioning the main combustion chamber casing. The circular base 1 is provided with a first protruding End 4 and a plurality of second protruding ends 5, the first protruding end 4 and the second protruding end 5 are evenly arranged along the circumference of the circular base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com