A silicon wafer automatic slice feeding mechanism

A technology of silicon wafers and feeding mechanism, which is applied to conveyor objects, electrical components, transportation and packaging, etc., can solve problems such as broken silicon wafers, and achieve the effect of uniform size, good verticality and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

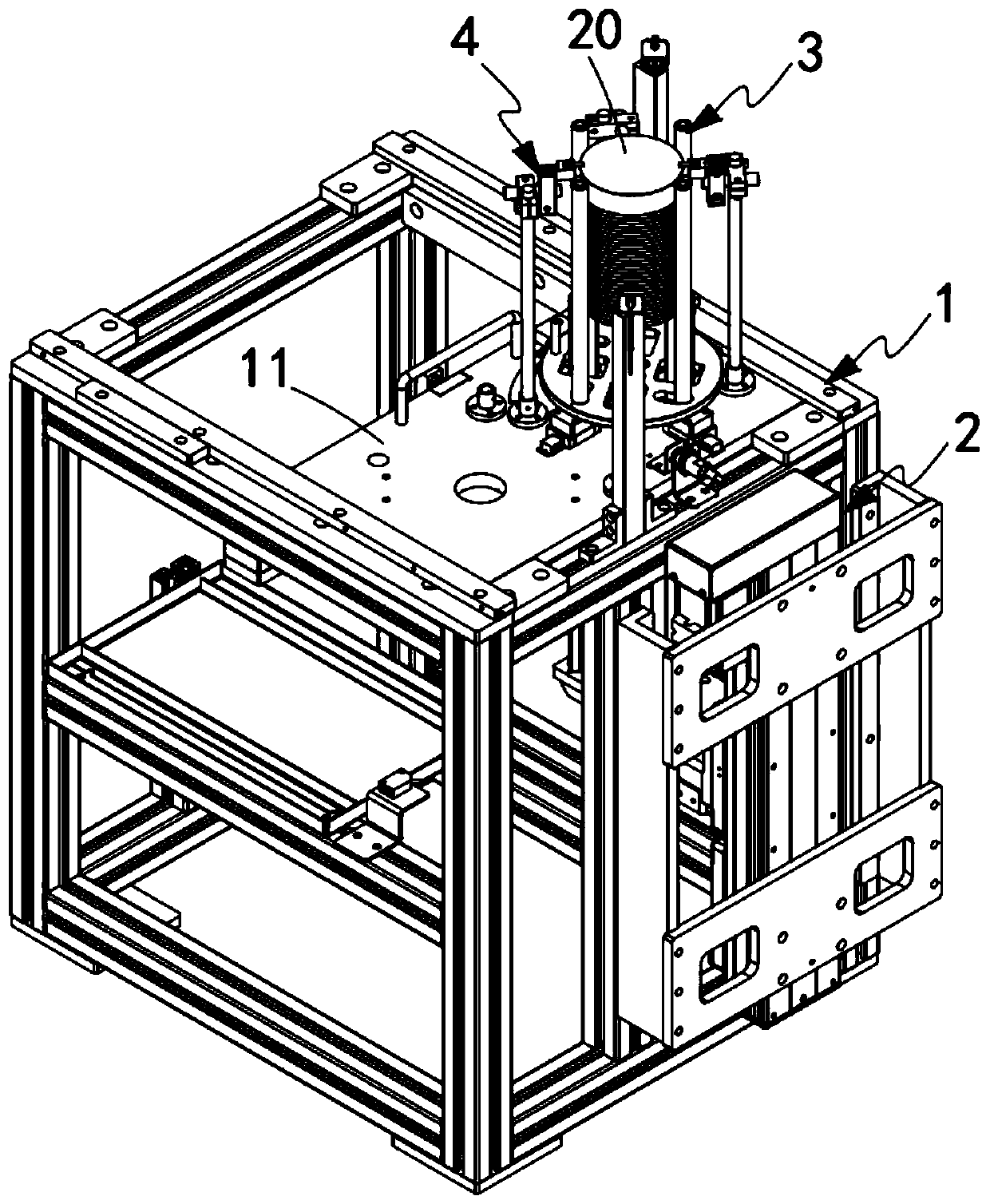

[0059] like Figure 1 to Figure 6 Shown, a kind of silicon wafer automatic slicing feeding mechanism comprises:

[0060] Installation frame 1, the top of described installation frame 1 is provided with workbench 11;

[0061] The feeding mechanism 2 vertically penetrates the workbench 11 and is installed on the installation frame 1, which includes a support assembly 21 and a lifting assembly 22, and the top of the support assembly 21 is stacked with silicon wafers 20. The lifting assembly 22 drives the silicon wafer 20 to lift;

[0062] The limit mechanism 3, the limit mechanism 3 is arranged on the workbench 11, it is arranged around the support assembly 21, and it includes a plurality of limit rods 31 arranged in parallel sliding, between the limit rods 31 forming a material area 30 for stacking the silicon wafers 20; and

[0063] Layering mechanism 4, described layering mechanism 4 is installed on the top of described material area 30, and it divides and is positioned at ...

Embodiment approach

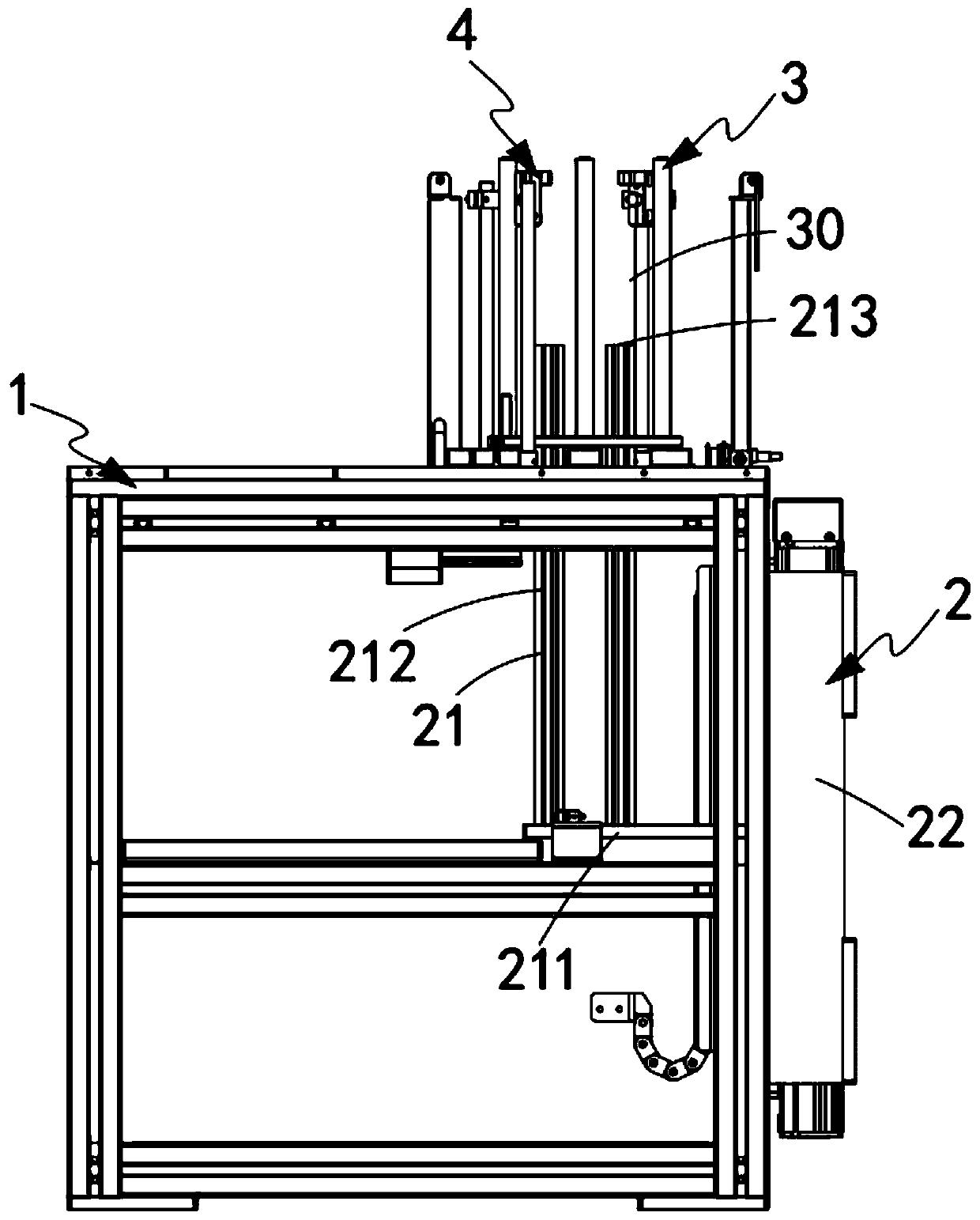

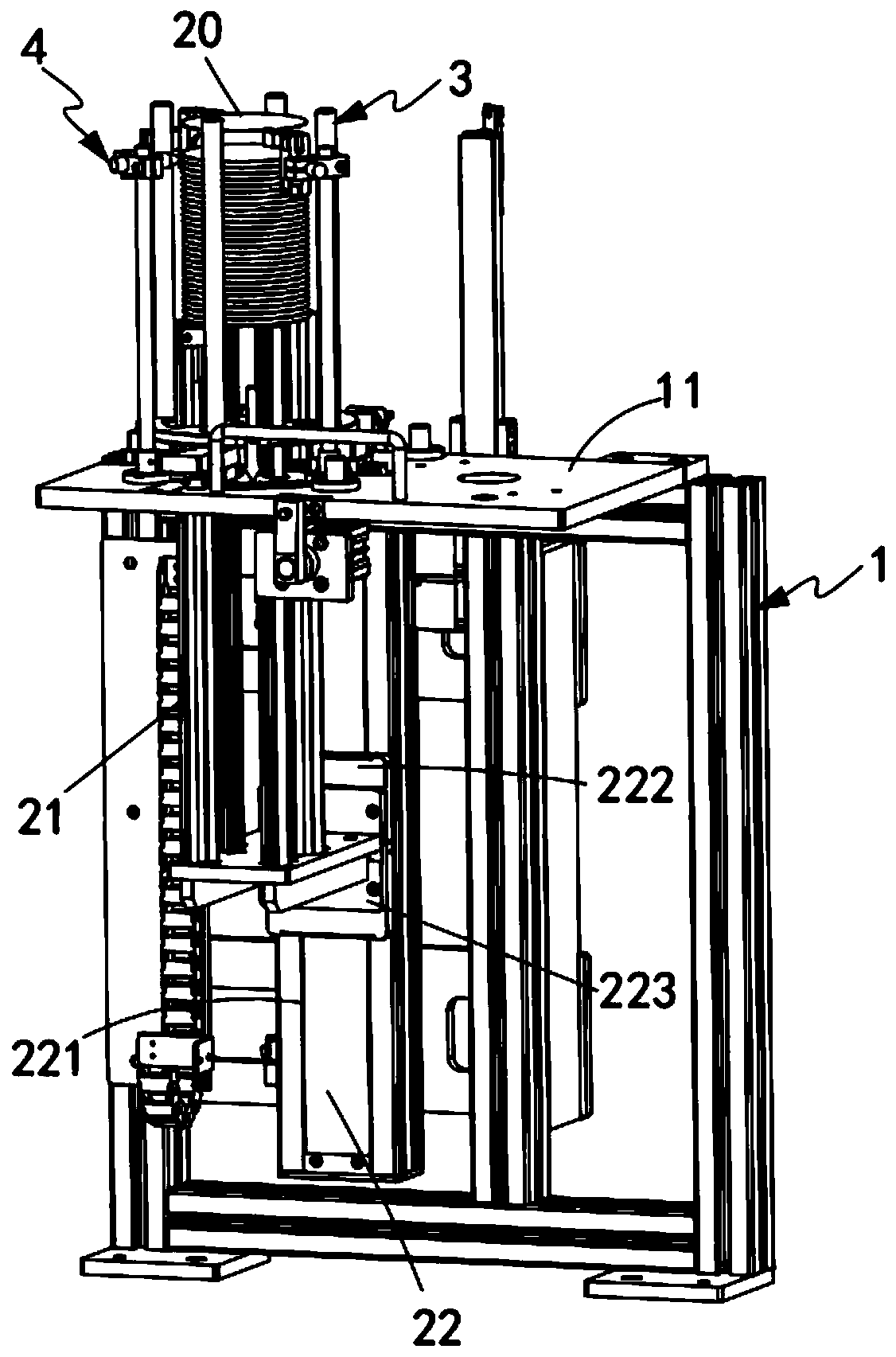

[0067] like figure 2 As shown, as a preferred embodiment, the support assembly 21 includes:

[0068] The mounting plate 211, the mounting plate 211 is horizontally arranged, it is connected with the lifting assembly 22, and it is driven by the lifting assembly 22 to lift and set in the vertical direction; and

[0069] Support rods 212, several of the support rods 212 are installed vertically on the mounting plate 211, the support rods 212 are equidistantly arranged along the lifting direction of the mounting plate 211, and the tops of the support rods 212 are matched to form A placement platform 213 for placing the silicon wafer 20 .

[0070] It should be noted that the number of support rods 212 in the present invention is preferably four, and the tops of the support rods 212 are arranged flat to form a placing platform 213 on which silicon wafers 20 are stacked.

[0071] like image 3 and Figure 4 As shown, as a preferred embodiment, the lifting assembly 22 includes: ...

Embodiment 2

[0096] Figure 10 It is a schematic structural view of Embodiment 2 of a silicon wafer automatic slice feeding mechanism of the present invention; as Figure 10As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0097] like Figure 10 and Figure 11 As shown, a silicon wafer automatic slice feeding mechanism, one side of the limit mechanism 3 is provided with a buffer mechanism 5, and the buffer mechanism 5 is arranged on the workbench 11, which includes:

[0098] A blanking container 51, a buffer liquid is contained in the blanking container 51;

[0099] A discharge handle 52, the discharge handle 52 is placed in the discharge container 51, and it is detachably arranged; and

[0100] An overflow container 53, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com