Grinding machining device and machining method for concentric circular arc groove of hard and brittle material workpiece

A concentric arc and grinding technology, which is applied in the direction of fixed grinding wheel devices, grinding workpiece supports, metal processing equipment, etc., can solve the problems of low fracture, difficult processing, cracks in workpieces, etc., and achieve high-efficiency grinding , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

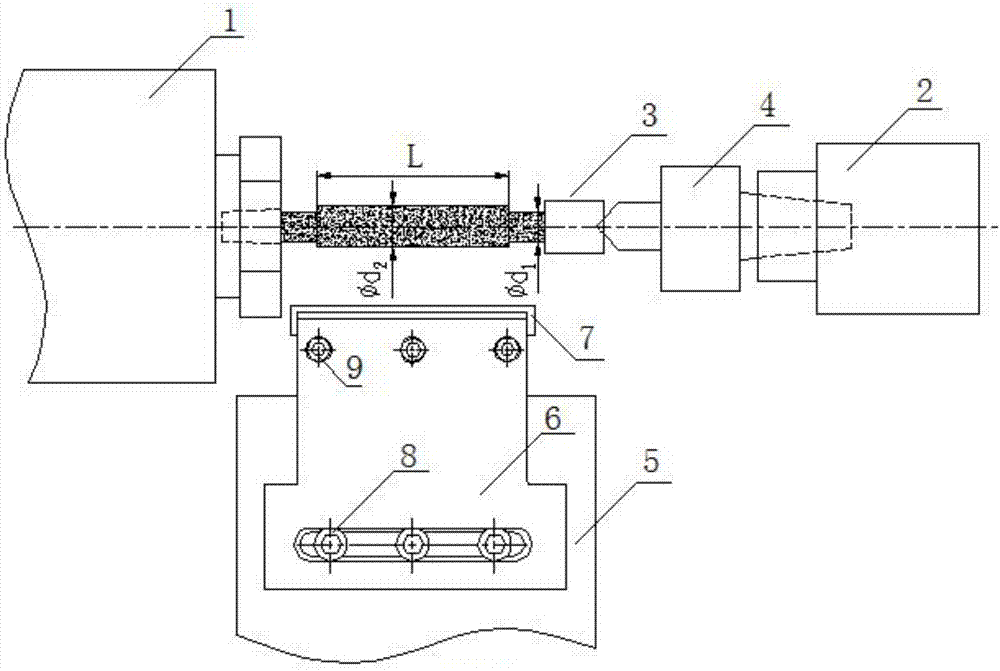

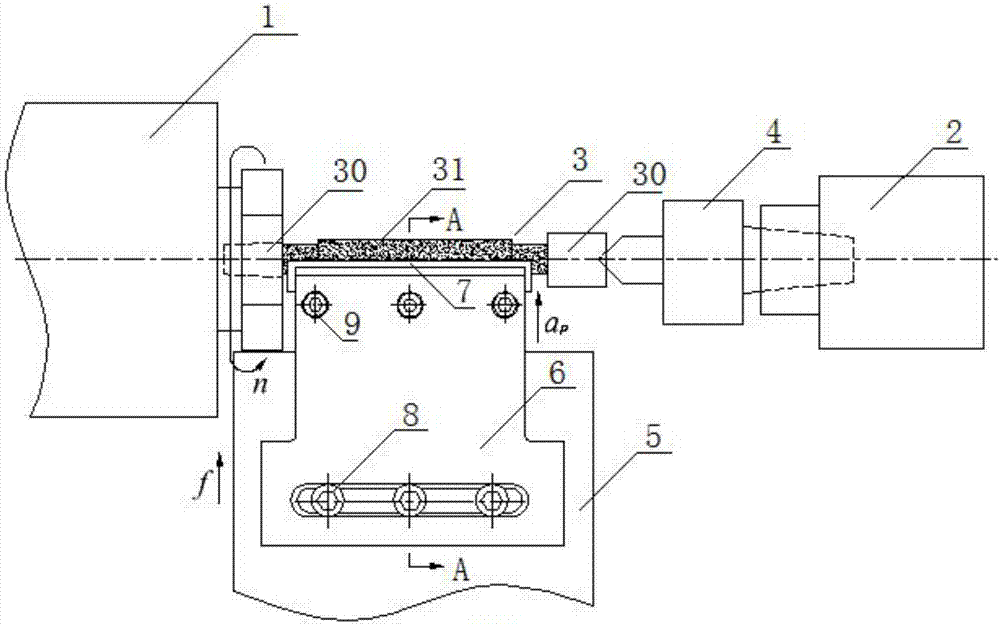

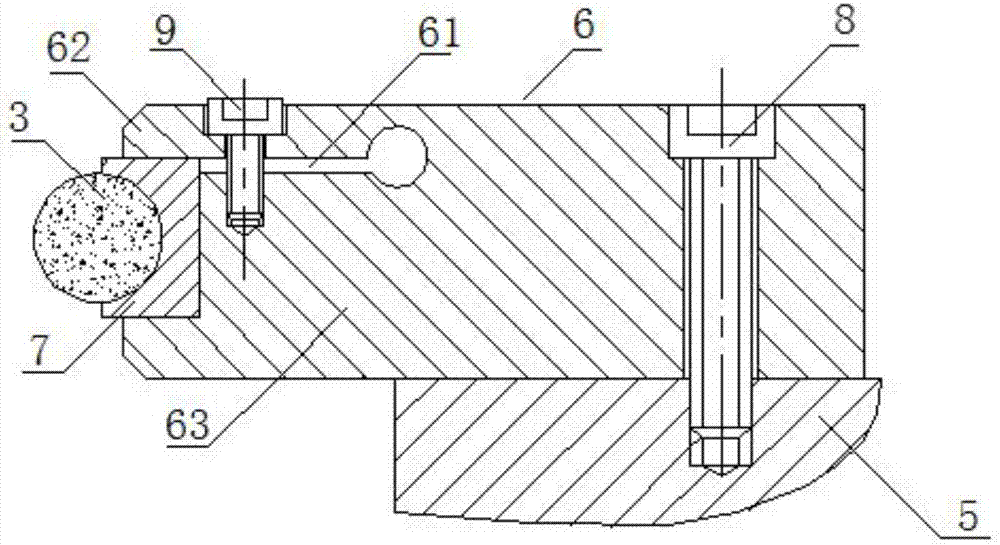

[0032] This embodiment provides a grinding device for concentric arc grooves of hard and brittle material workpieces, such as Figure 1 to Figure 6 As shown, it includes a lathe spindle 1, a lathe guide rail, a lathe tailstock 2, a forming grinding wheel 3 adapted to the external dimensions of the concentric arc groove, a clamping part 6 for fixing a workpiece 7, and a workpiece 7 The lathe tool holder pallet 5 of the feed speed and the back cutting amount; the lathe tailstock 2 is slidably arranged on the lathe guide rail; the forming grinding wheel 3 is detachably fixed on the lathe spindle 1 and the lathe between the tailstock 2 and is driven by the lathe spindle 1 to rotate; the clamping part 6 is detachably arranged on the lathe tool holder pallet 5, and the workpiece 7 is detachably mounted on the clamping On the component 6 and under the action of the feed speed of the lathe tool holder pallet 5, it is pressed against the forming grinding wheel 3 to realize grinding. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com