Production process of organic gel surface layer concrete porous water permeable bricks

A technology of concrete and organic glue, which is applied in the direction of manufacturing tools, ceramic molding machines, cement mixing devices, etc., can solve the problems of infiltration into the ground, poor water permeability of permeable bricks, etc., to achieve enhanced service life, good water seepage performance, and improved water seepage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

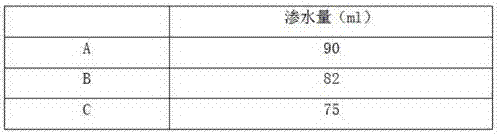

Embodiment 1

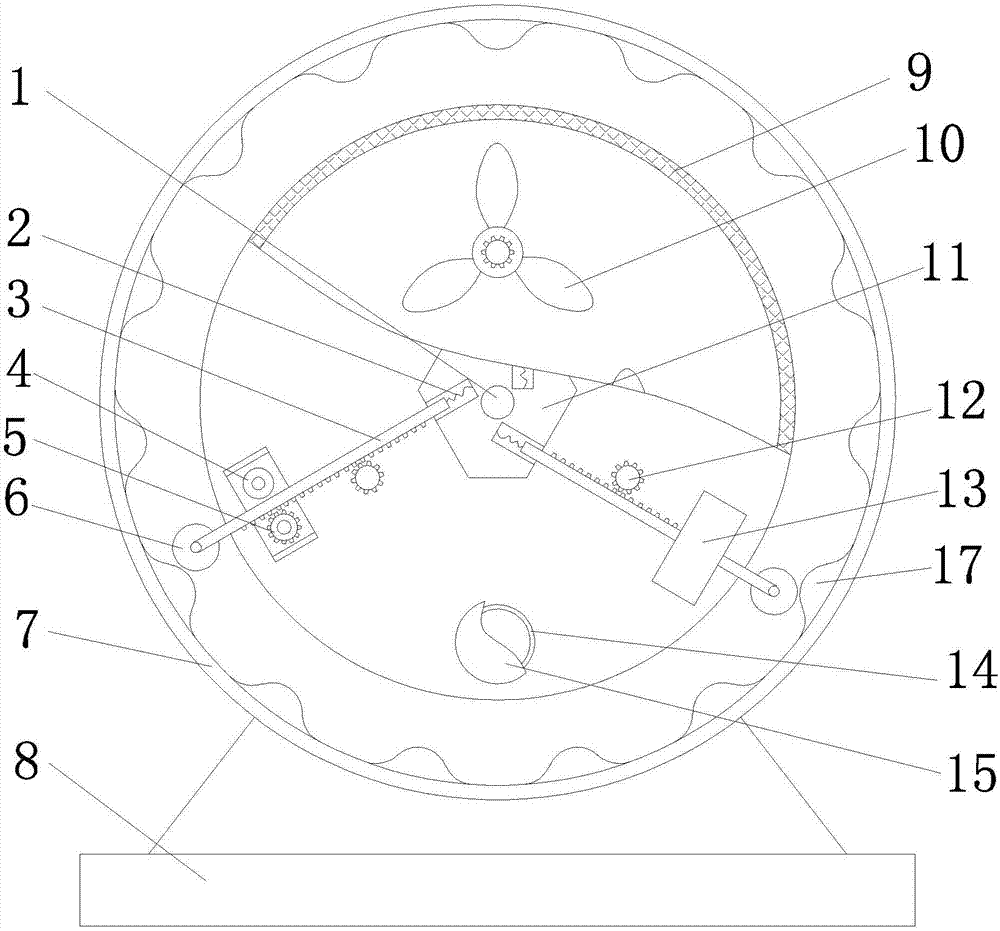

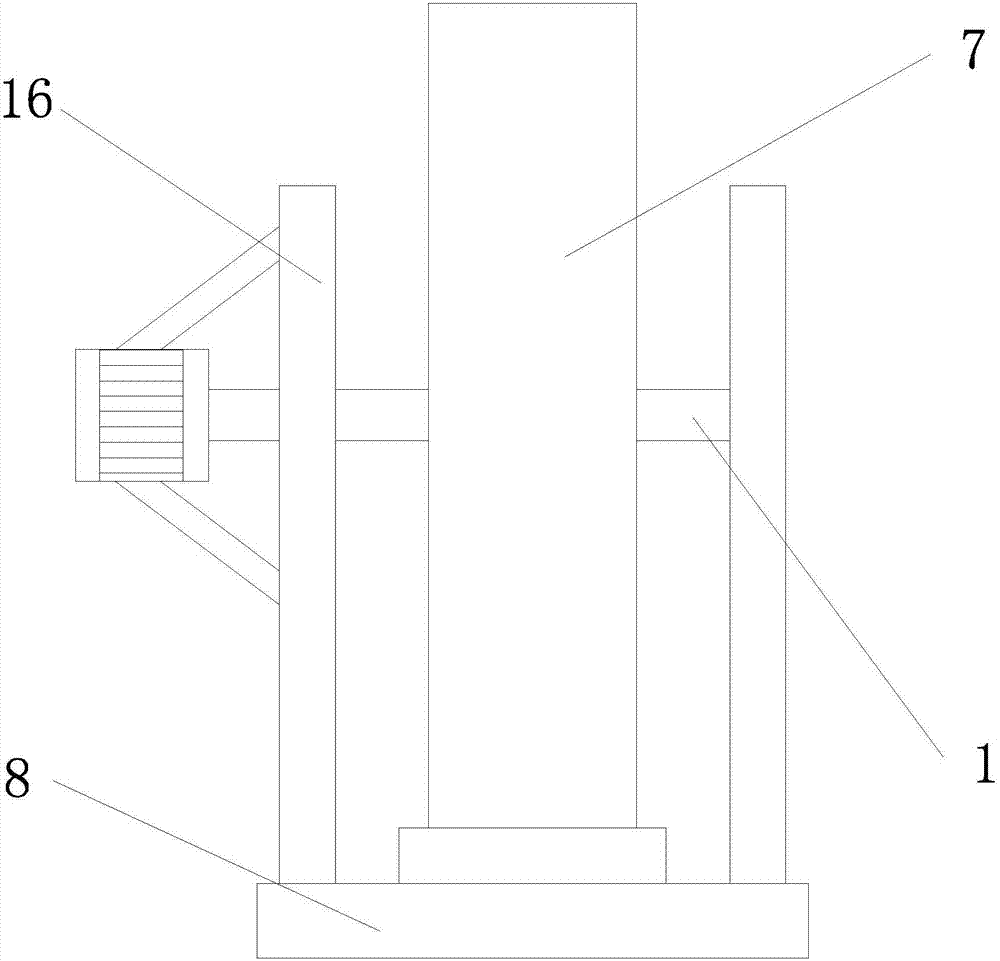

[0023] refer to Figure 1-2 , a concrete mixing device for the surface layer of organic gelling material, comprising a base 8, the top of the base 8 is respectively fixedly connected with a circular frame 7 and two supports 16, and the circular frame 7 is located between the two supports 16, and the circular The inner circle of the frame 7 is provided with a circular mixing bucket 9, and the center of the circular mixing bucket 9 is fixedly inserted with a first rotating shaft 1, and one end of the first rotating shaft 1 is rotationally connected with the side wall of one of the brackets 16, and the first rotating shaft The other end of 1 runs through another bracket 16 and is connected with the output end of the motor, and the side wall of the motor is connected with the bracket 16 through a support rod, and the inner wall of the circular mixing bucket 9 is rotatably connected with an eccentrically arranged second rotating shaft, the second rotating shaft A stirring paddle 10...

Embodiment 2

[0031] refer to Figure 1-2 , a concrete mixing device for the surface layer of organic gelling material, comprising a base 8, the top of the base 8 is respectively fixedly connected with a circular frame 7 and two supports 16, and the circular frame 7 is located between the two supports 16, and the circular The inner circle of the frame 7 is provided with a circular mixing bucket 9, and the center of the circular mixing bucket 9 is fixedly inserted with a first rotating shaft 1, and one end of the first rotating shaft 1 is rotationally connected with the side wall of one of the brackets 16, and the first rotating shaft The other end of 1 runs through another bracket 16 and is connected with the output end of the motor, and the side wall of the motor is connected with the bracket 16 through a support rod, and the inner wall of the circular mixing bucket 9 is rotatably connected with an eccentrically arranged second rotating shaft, the second rotating shaft A stirring paddle 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap