Paper card packaging box

A packaging box and paper card technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of easy displacement, unstable protection performance, low assembly efficiency of paper card packaging boxes, etc., and achieve high connection strength , stable protection and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

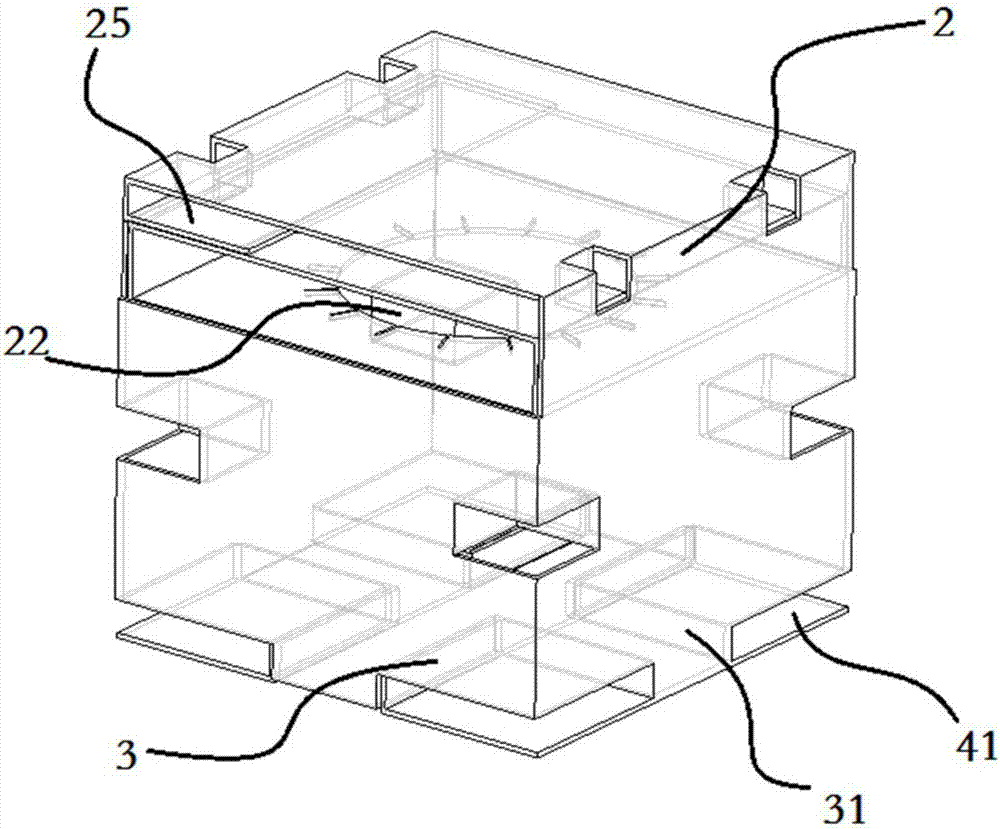

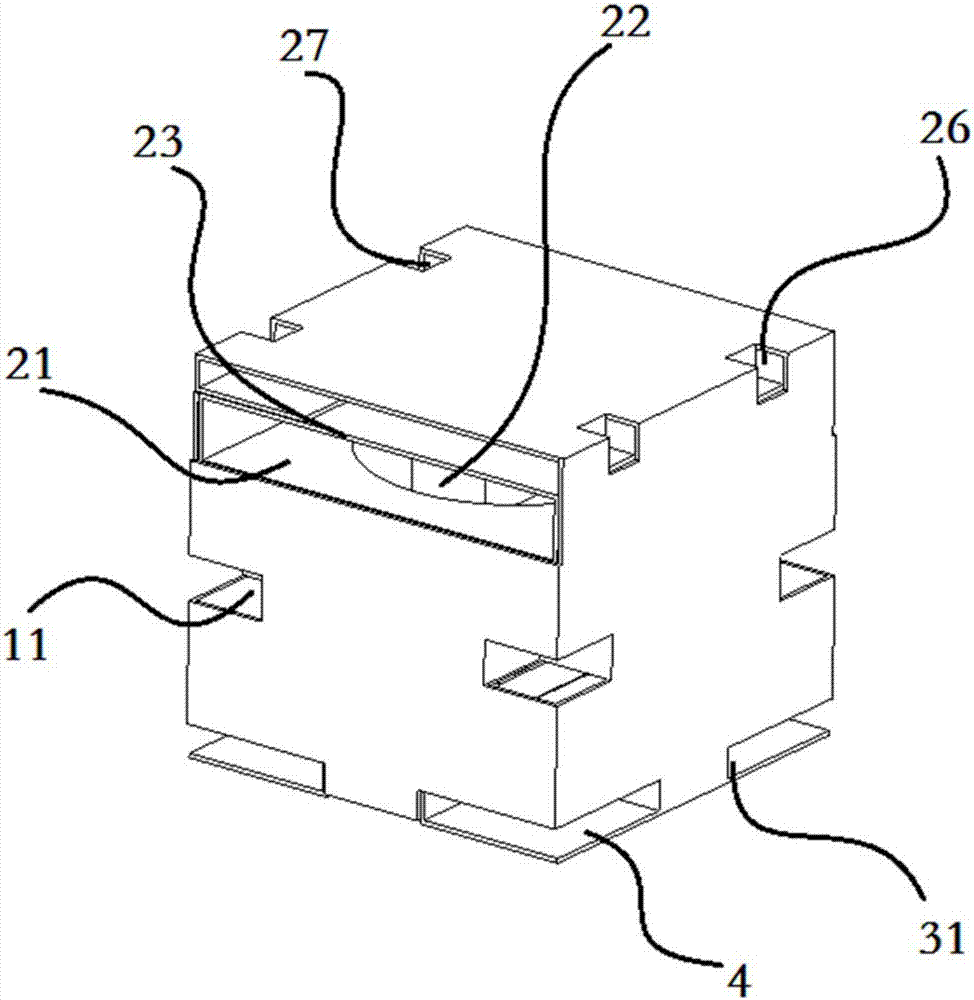

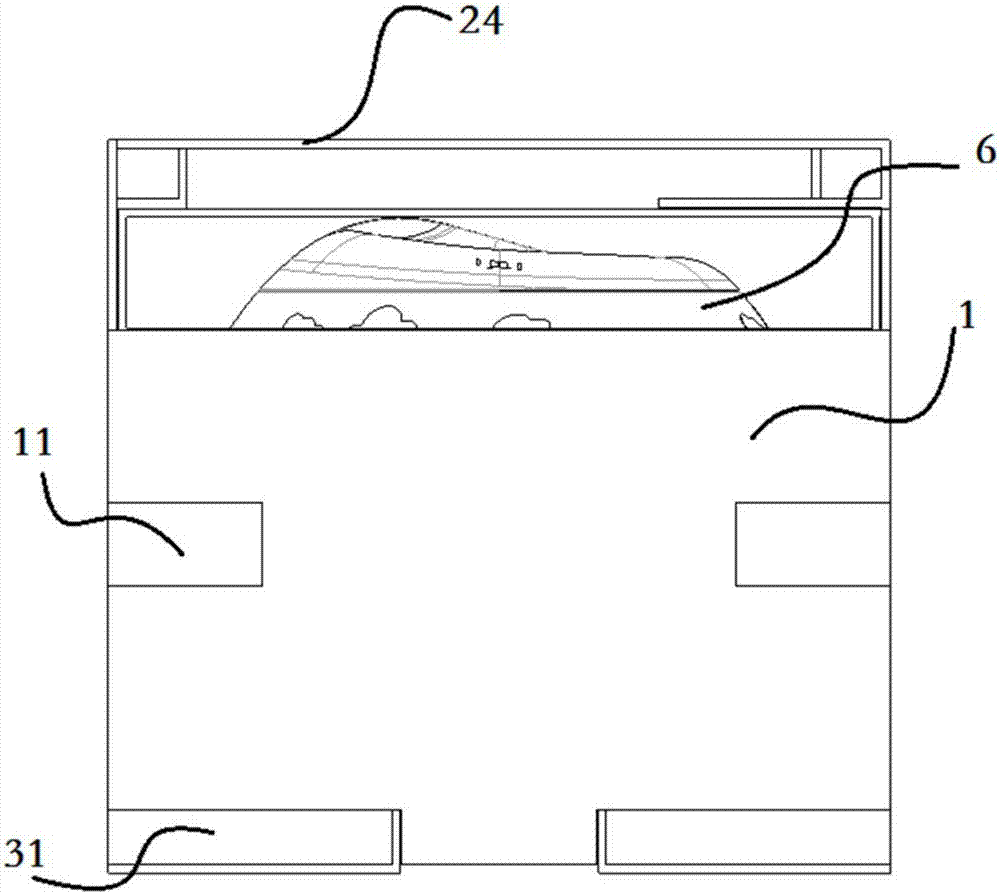

[0047] Such as Figure 1-4 As shown, the paper card packaging box provided in this embodiment includes a box body 1, and the two ends of the box body 1 are connected with a first end buffer layer 2 and a second end buffer layer 3 for buffering and protecting both ends of the product. , also includes a positioning plate 21 located between the first end buffer layer 2 and the box body 1, the positioning plate 21 is formed with a positioning hole 22 suitable for the corresponding end of the product to extend into, which can provide basic positioning for the product , and the box body 1, the first end buffer layer 2 and the second end buffer layer 3, and the positioning plate 21 are folded from a cardboard, and the integrally formed cardboard box has both first and second ends The inner cushion layer 3 can provide cushioning protection for both ends of the product. It does not need to be assembled multiple times during packaging. It can be completed by directly putting the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com