Rapid forming device of oil cake used for sesame oil processing

A molding device, sesame oil technology, applied in transportation and packaging, fat oil/fat production, mixer, etc., can solve the problems of clear fragrance, oil production rate and oil quality, loss of nutrients and active substances, etc., and achieve improvement Quality and taste, fast molding speed, good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

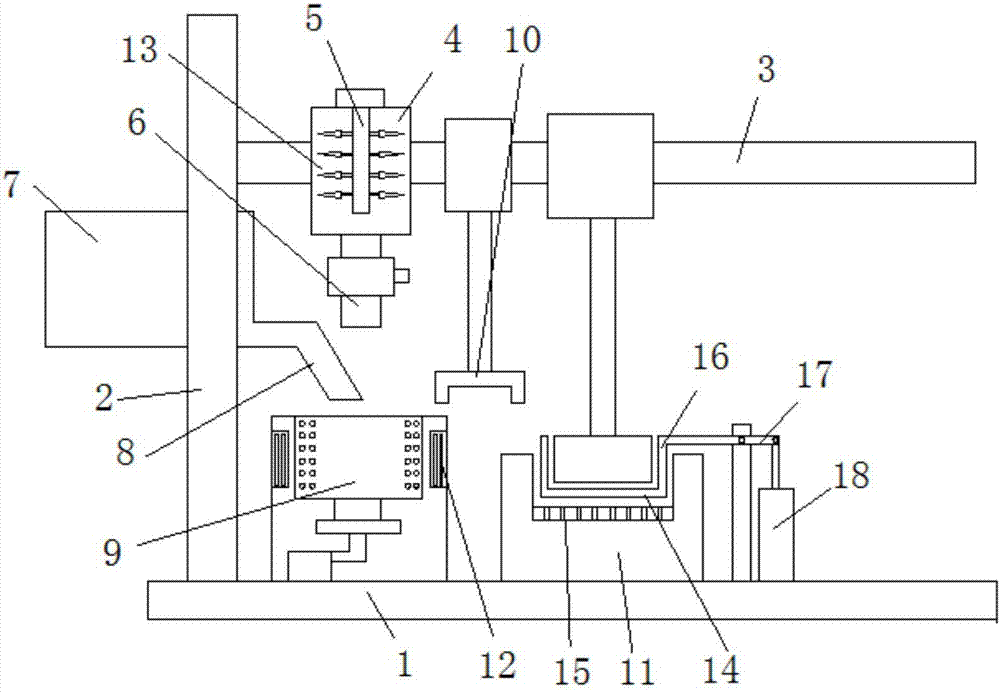

[0011] Referring to the accompanying drawings, a rapid prototyping device for oil cakes for sesame oil processing, comprising a base 1, a column 2 is arranged on the base 1, a beam plate 3 is arranged on the side wall of the column 2, and a beam plate 3 is fixedly installed There is a walnut powder crushing tube 4, the crushing tube 4 is provided with a rotating shaft 5, the bottom of the crushing tube 4 is provided with a discharge pipe 6, and a sesame raw material storage bin is fixedly installed on the side wall of the column 2 7. The side wall of the sesame storage bin 7 is provided with a feeding pipeline 8, the stirring centrifuge 9 is connected below the feeding pipeline 8, and a manipulator 10 is slidably installed on the beam plate, and the manipulator 10 can stir the The raw material in the centrifugal drum 9 is transported to the oil cake forming platform 11 on one side.

[0012] A heating rod 12 is arranged on the side wall of the stirring centrifugal drum 9 .

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap