Sampling pipe connecting device for coal-mine gas extraction

A coal mine gas and connection device technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as uneconomical, cracks, and drilling air leakage, and achieve the effect of improving the effect, simple structure, and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

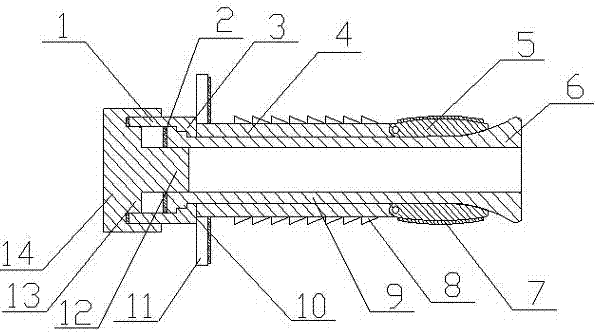

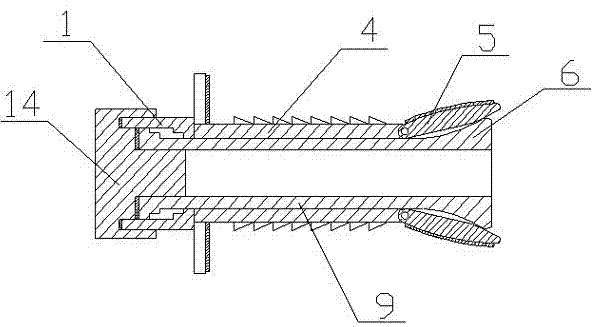

[0022] A coal mine gas extraction sampling pipe connection device of the present invention is realized in this way. When in use, when performing coal mine gas extraction, first put the main rod body (4) into the borehole, and make the stop ring (11) stick At the mouth of the drill hole, then rotate the connecting sleeve (1), because the main snap ring (3) on the connecting sleeve (1) and the auxiliary snap ring (10) on the connecting cylinder (9) are clamped, and then the connecting sleeve (1) ) drives the connecting cylinder (9) to rotate, because the connecting cylinder (9) and the main rod body (4) are screwed together, and then the connecting cylinder (9) moves out of the main rod body (4) during the rotation process, and the connecting cylinder (9) drives The compression block (6) moves into the main rod body (4), and since the diameter of the compression block (6) gradually increases from one end to the other end, the compression block (6) gradually expands the multiple e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com