Metal rubber elastic element for flexible robot joints capable of measuring torques

A technology of robot joints and metal rubber, applied in the field of robots, can solve the problems such as inability to accurately estimate the torque, unstable nature and limited life of passive vibration damping elastic components, and achieve the effects of large flexibility, good vibration damping effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

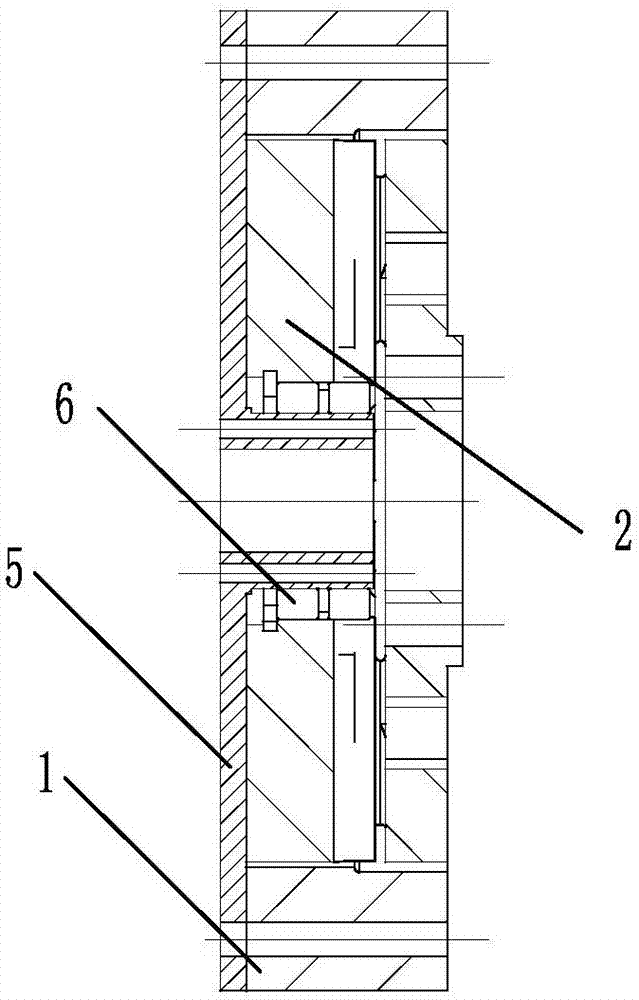

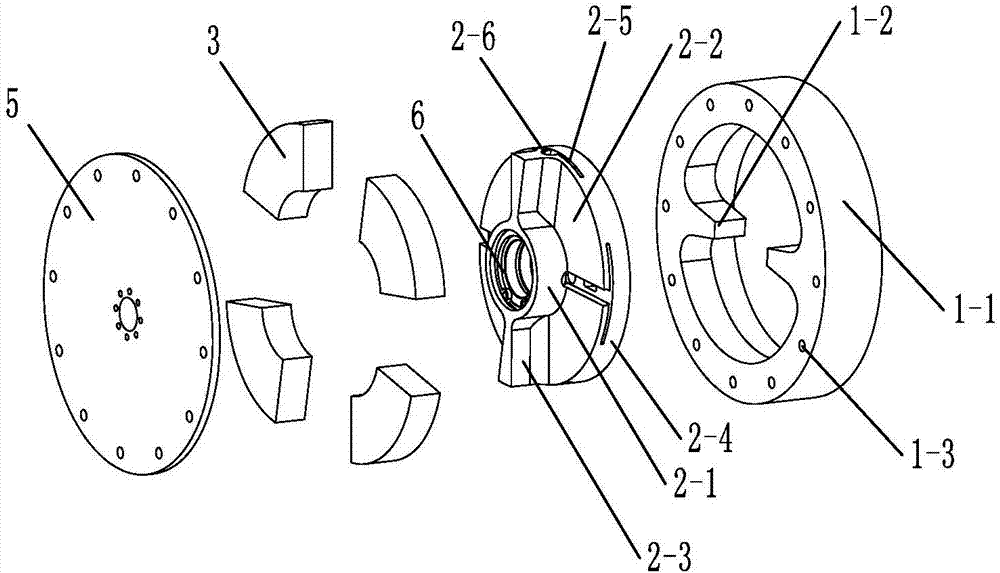

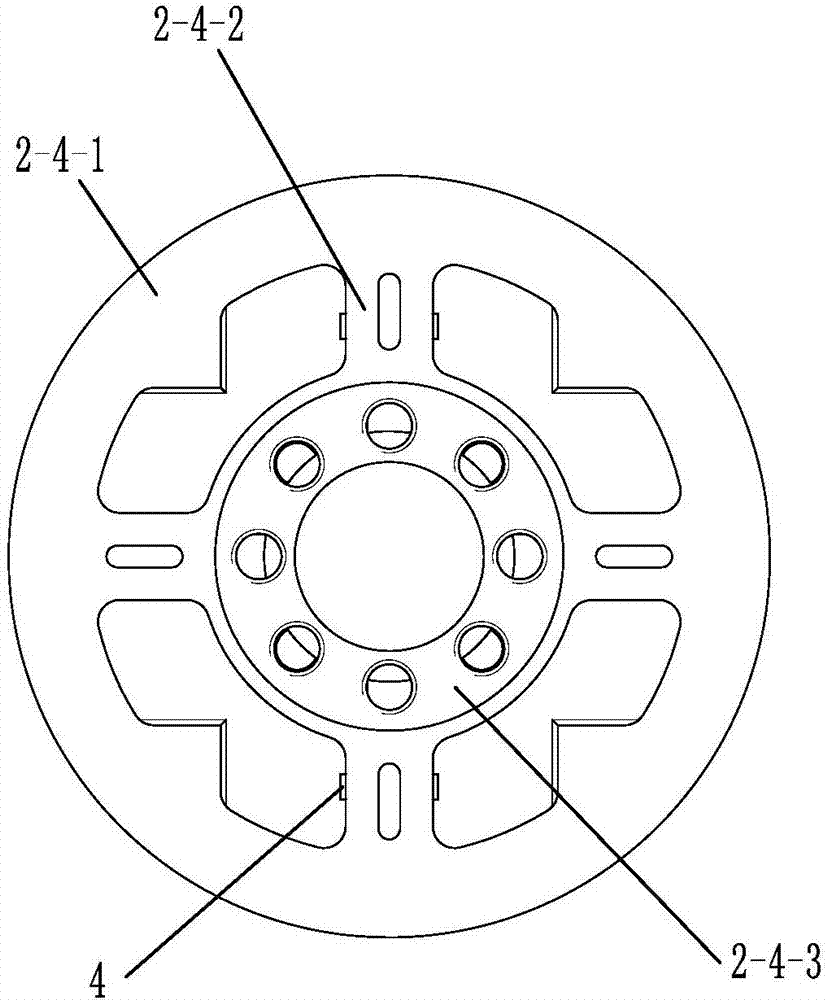

[0021] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, the metal rubber elastic element used in the flexible robot joint that can measure the moment of this embodiment, it includes the outer ring basic body 1, the inner ring-sensor assembly 2, the baffle plate 5, the bearing group 6, a plurality of Metal rubber sheet 3 and multiple resistance strain gauges 4, outer ring basic body 1 is set on inner ring-sensor assembly 2, multiple resistance strain gauges 4 are installed on inner ring-sensor assembly 2, bearing group 6 is installed on On the inner ring-sensor assembly 2, a plurality of metal rubber sheets 3 are embedded in the space enclosed by the outer ring basic body 1 and the inner ring-sensor assembly 2, and the baffle plate 5 is mounted on the outer ring basic body 1.

[0022] Structurally, the present invention adopts split design. This embodiment is a rotary elastic element for a joint of a flexible robot that integrates torqu...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1 to Figure 2 Describe this embodiment, the outer ring basic body 1 of this embodiment includes an outer ring 1-1 and an outer ring baffle 1-2, the outer ring 1-1 is an annular outer ring, and the ring body of the outer ring 1-1 is along the A plurality of connection holes 1-3 are provided in the axial direction of itself, and the outer ring baffles 1-2 are fixedly installed on the inner side wall of the outer ring 1-1 in an annular array. With such an arrangement, the structure is simple, and it is convenient to provide support and connection for the basic body 2 of the inner ring. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 1 to Figure 2 The present embodiment will be described. In this embodiment, the outer ring 1-1 and the outer ring retainer 1-2 are integrally formed. Such setting facilitates production and manufacturing, saves production and manufacturing costs and production cycles. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap