Modal analyzing method for high-frequency blade based on noncontact vibration measurement and simulating calculation

A technology of simulation calculation and modal analysis, applied in the direction of calculation, design optimization/simulation, measurement device, etc., can solve the problems of high test difficulty and poor accuracy, and achieve accurate natural frequency value, frequency and mode shape, The effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

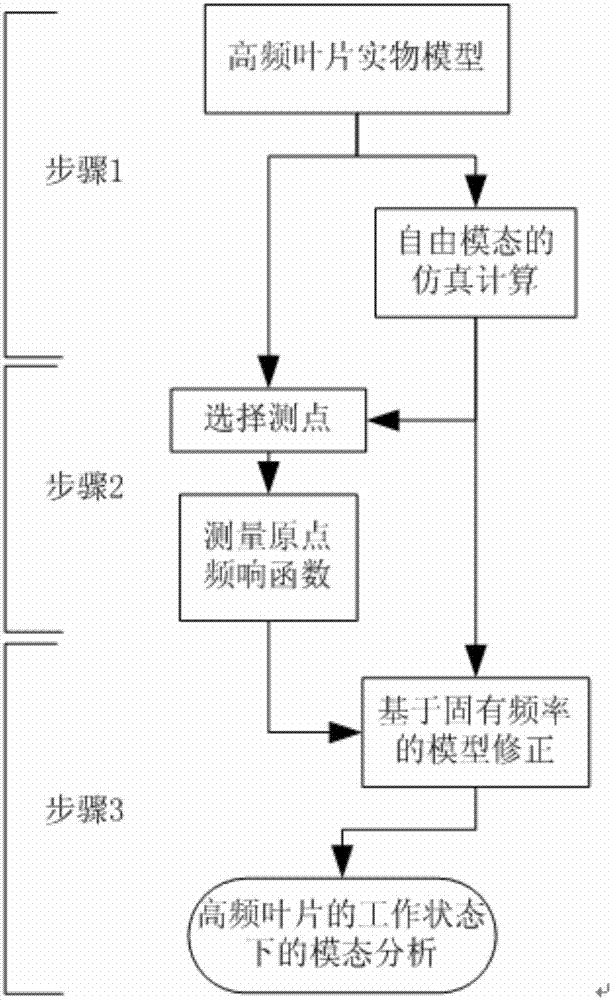

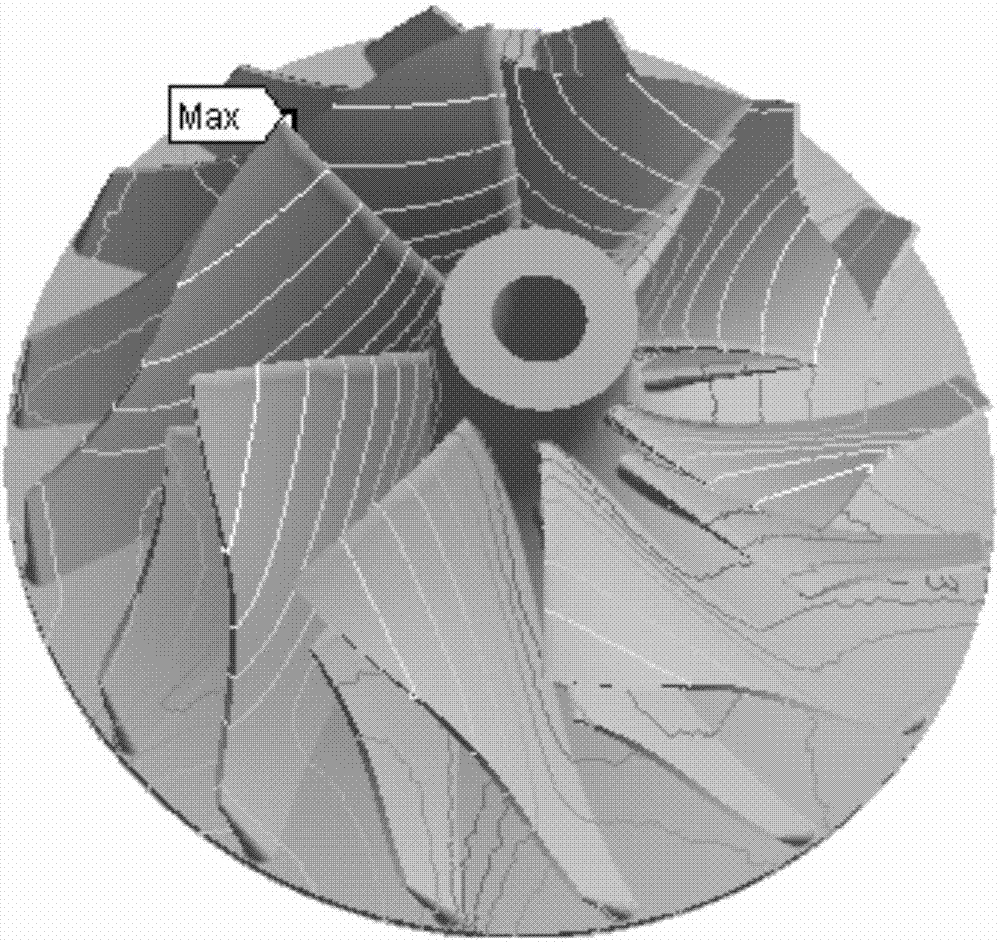

[0024] This embodiment provides a high-frequency blade modal analysis method based on non-contact vibration measurement and simulation calculation. parameters and Poisson’s ratio to obtain accurate blade modes, and provide reliable analysis benchmarks for faults such as engine blade resonance and fatigue aging. The details include the following steps, refer to the attached figure 1 :

[0025] (1) Using the finite element calculation method to calculate the free mode of the high-frequency blade, and obtain the natural frequency and mode shape of the free mode;

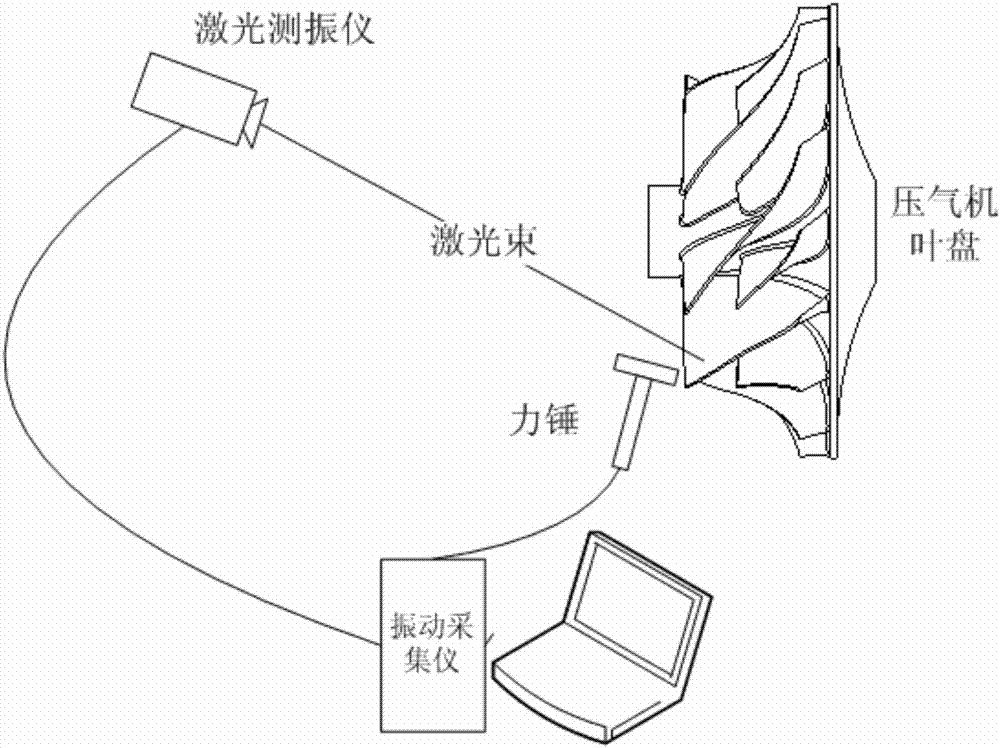

[0026] (2) According to the calculated mode shape, select the measuring point, and use the laser Doppler vibration measurement method to test the frequency response function of the blade origin to obtain the true natural frequency of the blade;

[0027] (3) Modify the elastic modulus and Poisson's ratio parameters of the simulation model so that the calculation results of the simulation model are consistent with the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com