Pulverized coal particle detection and sampling device

A particle detection and sampling device technology, applied in the field of pulverized coal particle detection and sampling device, pulverized coal particle detection and sampling device field, can solve problems such as inability to sample, poor sample uniformity, long time, etc., to avoid influence and avoid sampling dust. Uniform, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

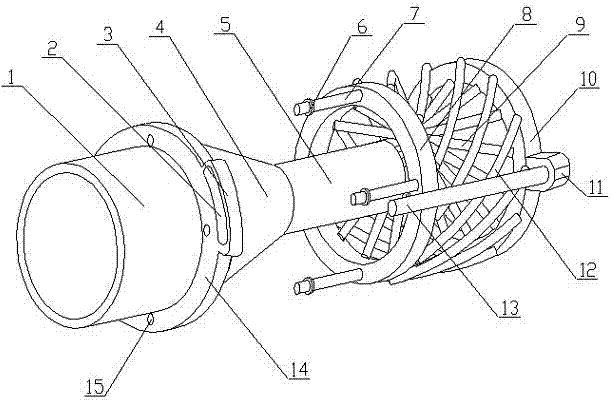

[0023] A pulverized coal particle detection and sampling device of the present invention is realized in this way, consisting of a main body (1), an arc-shaped groove (2), an arc-shaped boss (3), a tapered connecting pipe (4), and a plastic hose (5 ), limit ring (6), support rod (7), fixed ring (8), extrusion rod (9), support ring (10), support ear (11), elastic rod (12), screw rod (13) , a snap ring (14) and a connecting hole (15), the fixed ring (8) is connected with a support ring (10) through a plurality of elastic rods (12), and the fixed ring (8) and the support ring (10) are axis, the distance between the two adjacent elastic rods (12) is equal, the elastic rods (12) are quarter turn helical, the elastic rods (12) are tube springs, the fixed The distance between the ring (8) and the support ring (10) is equal to 1 / 4 pitch of the elastic rod (12), and one end of a plurality of extrusion rods (9) is respectively placed on the support ring (10), and along the support ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com