Full-digital heating control system for six-surface top press

A six-sided top press, all-digital technology, applied in the direction of digital control, general control system, control/regulation system, etc., can solve the problems of no automatic protection function, high-frequency signal interference, difficulty in fault inquiry, etc., to save costs and maintenance difficulty, powerful protection function, and the effect of optimizing hardware design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with embodiment.

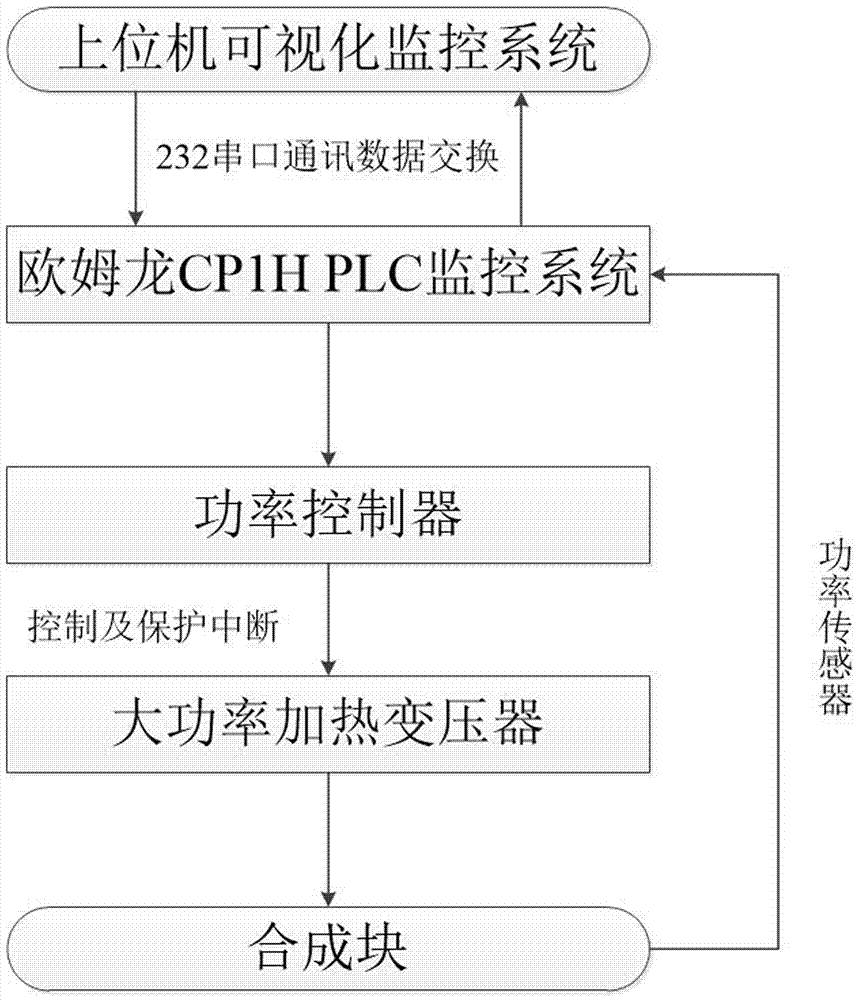

[0015] refer to figure 1 , the fully digital heating control system of the six-sided top press in this embodiment includes a host computer visual monitoring system, a PLC monitoring system, a power controller, and a high-power heating transformer. The host computer visual monitoring system exchanges data with the PLC monitoring system through 232 serial port communication , the PLC monitoring system is connected with the power controller, the power controller controls the heating voltage of the synthesis block through the high-power heating transformer, the heating power signal in the synthesis block is sent to the upper computer visual monitoring system through the power sensor through the acquisition device, and the upper computer is visualized The monitoring system transmits the data to the PLC monitoring system, and the PLC monitoring system transmits the received data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com