Fluoroplastic insulated and high-temperature-resistant power cable

A power cable, high temperature resistant technology, applied in the field of fluorine plastic insulated high temperature resistant power cables, can solve the problems of crisis workers' life and health, easy damage to cable skin, cable core damage, etc., to reduce potential safety hazards, compact internal structure, extend The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

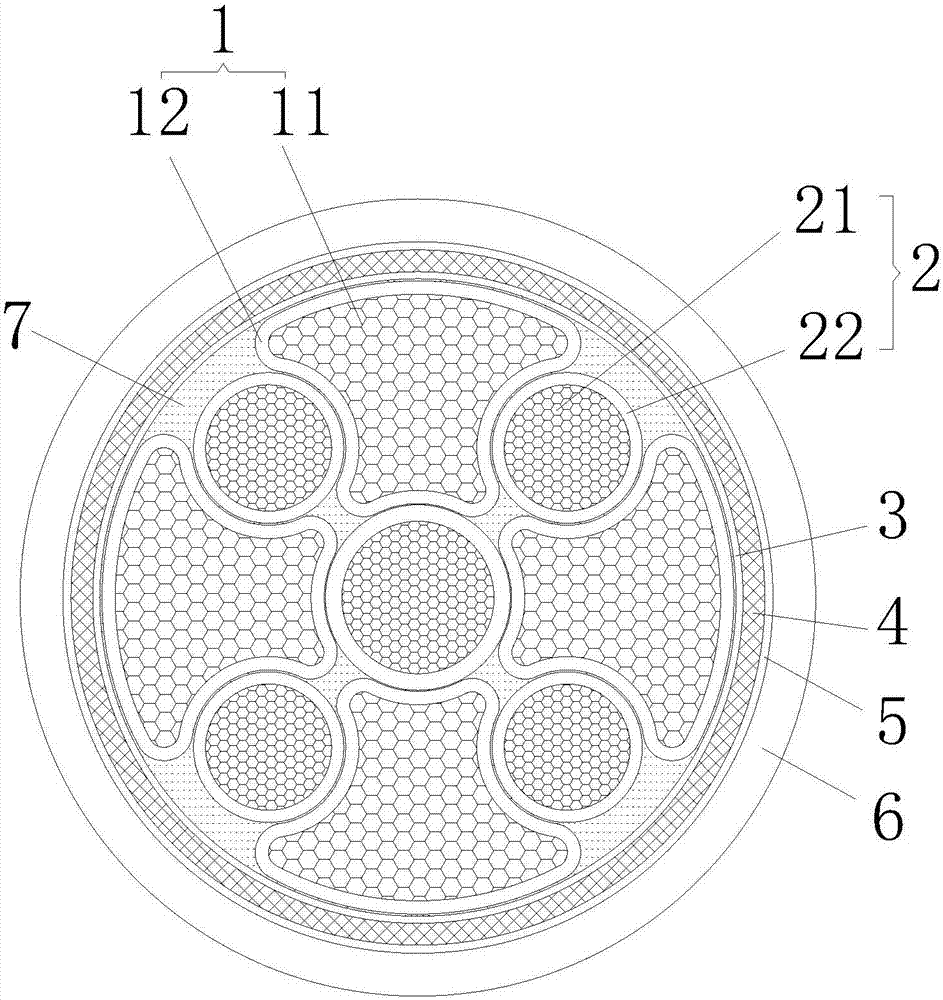

[0016] Such as figure 1 As shown, a fluorine plastic insulated high temperature resistant power cable includes a number of fan-shaped cores 1 evenly distributed, and the center of the distribution of the fan-shaped cores 1 is extruded with a circle between adjacent fan-shaped cores 1 The wire core 2, the outside of the fan-shaped wire core 1 and the circular wire core 2 are covered with an inner lining layer 3, a metal armor 4, a tape layer 5, and an outer sheath 6 in sequence from the inside to the outside, and the inner lining layer The inside of 3 is provided with filler 7, and described filler is PP filler.

[0017] Based on the above, it can be seen that this installation structure can ensure that when the number of wire cores wrapped inside the cable is large, it can also achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com