CMOS image sensor and manufacturing method thereof

A technology of image sensor and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as low cost and influence on process stability, achieve convenient mass production, save photolithographic plates, and improve The effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

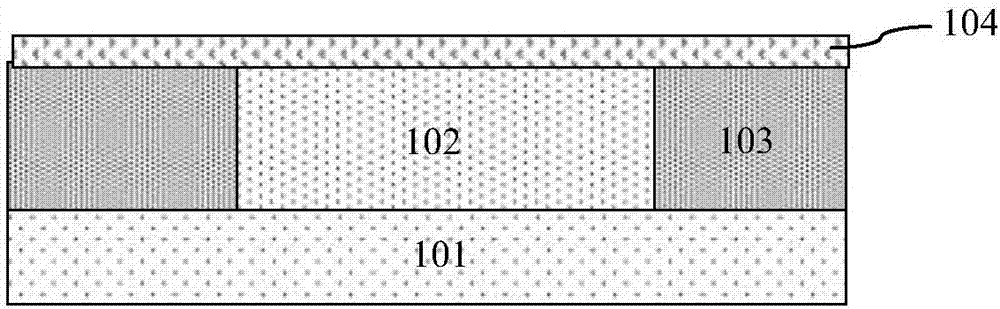

[0044] Such as Figure 5 What is shown is a schematic structural diagram of a photodiode of each pixel unit of a CMOS image sensor according to an embodiment of the present invention; each pixel unit of the CMOS image sensor provided by the present invention includes: an N-type injection region 2 and a P-type injection region 4.

[0045] The N-type implanted region 2 is formed on the surface of the P-type semiconductor substrate 1 and a PN junction diode formed between the N-type implanted region 2 and the P-type semiconductor substrate 1 serves as a photosensitive diode; Zone 2 stores photo-generated electrons after the photodiode is exposed to light.

[0046] The top surface structure of the N-type injection region 2 is circular or polygonal.

[0047] Preferably, a P-type epitaxial layer is further formed on the surface of the P-type semiconductor substrate 1, and the N-type implanted region 2 is formed in the P-type epitaxial layer. The P-type semiconductor substrate 1 is a P-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com