Three-phase permanent-magnet brushless mechanoelectrical transduction gear outer rotor motor

An external rotor motor, permanent magnet brushless technology, used in motors, AC motor control, electromechanical devices, etc., can solve the problems of increasing vehicle weight, occupying space, poor practicability, etc., to ensure reliable starting, improve starting efficiency, and start Small torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

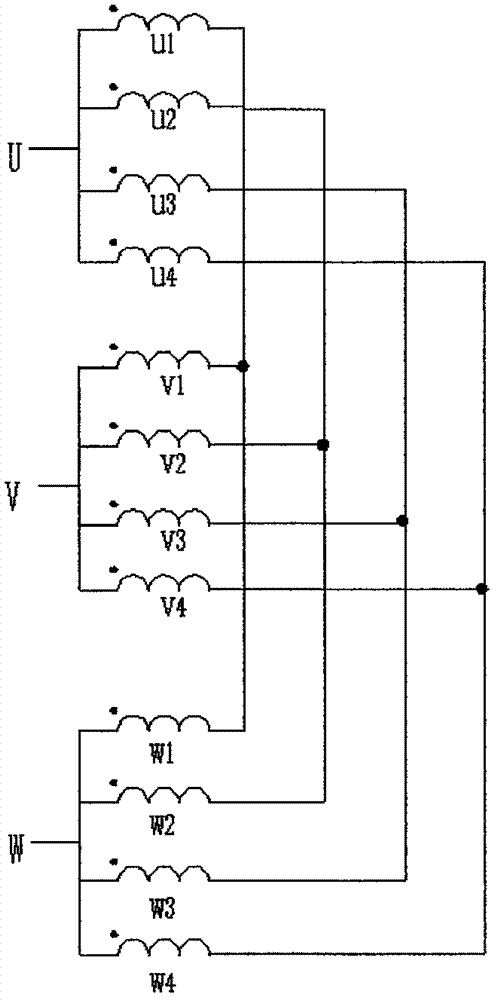

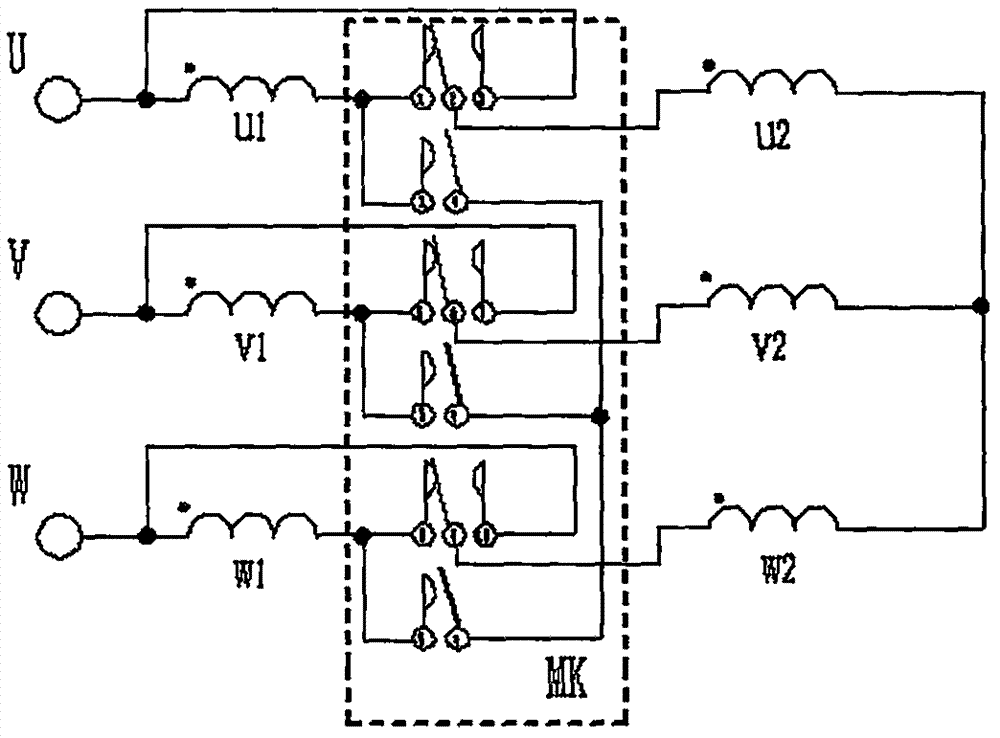

[0042] exist figure 1 and figure 2 Among them, the contact electrodes ① of the multi-contact electrode integrated high-stability magnetic latching relay (MK) are in contact with ②, ⑤ and ⑥, ⑧ and ⑨, and the contact electrodes ① and ④, ⑤ and ④, ⑧ and ④ are disconnected, that is The tail end of phase winding unit u1 is connected to the head end of u2, the tail end of phase winding unit v1 is connected to the head end of v2, the tail end of phase winding unit w1 is connected to the head end of w2, the tail ends of u2, v2 and w2 The terminals are connected together to realize the series connection of the phase winding units, which is the first gear state of the second gear motor of the first embodiment of the three-phase permanent magnet brushless electric conversion gear outer rotor motor.

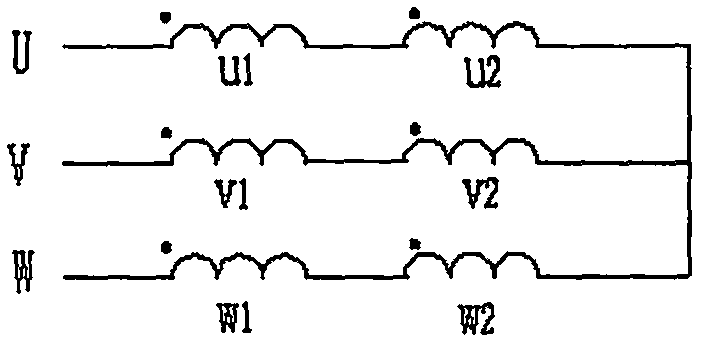

[0043] exist image 3 and Figure 4 Among them, the contact electrode ③ of the multi-contact electrode integrated high-stability magnetic latching relay (MK) is in contact with ②, ⑦ and ⑥...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com