High-precision stick-slip piezoelectric rotating table and driving method thereof

A high-precision, rotary table technology, used in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

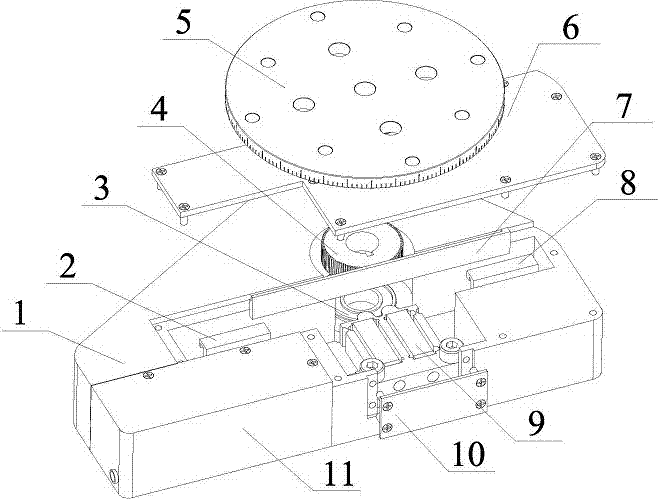

[0056] Specific implementation mode one: combine Figure 1~Figure 14 This embodiment is described. This embodiment provides a specific implementation of a high-precision piezoelectric stick-slip rotary table that realizes double-stacked double-drive foot stator assemblies. The specific implementation of the high-precision piezoelectric stick-slip rotary table with double-stacked double-drive foot stator assembly is described as follows:

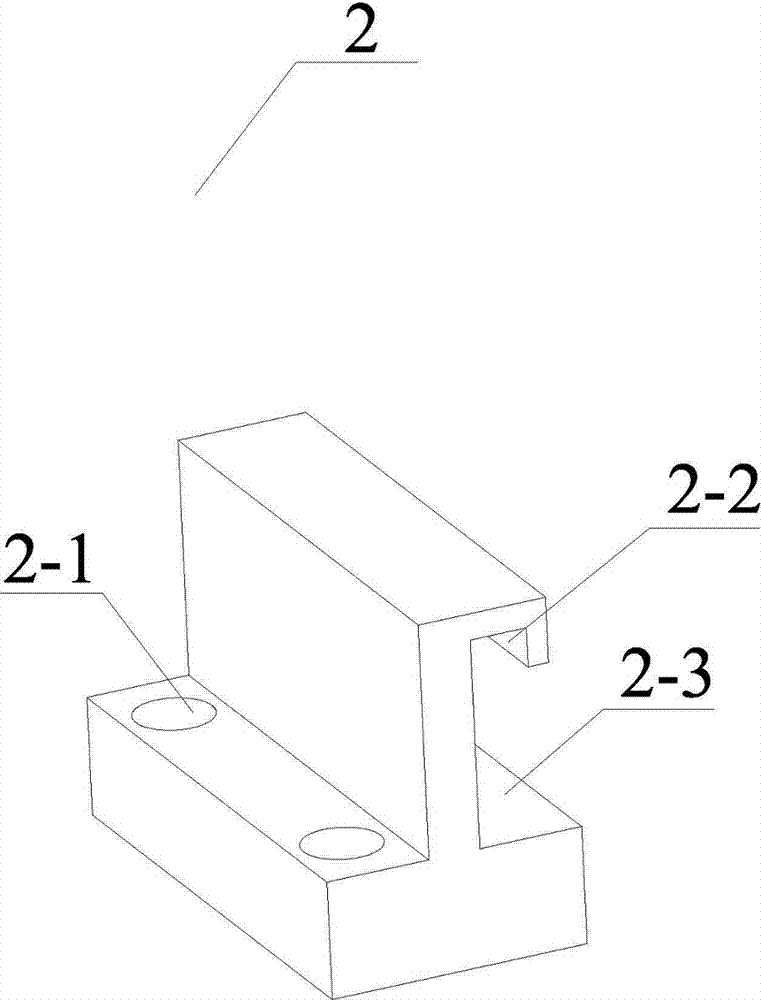

[0057] The high-precision piezoelectric stick-slip rotary table of the dual-stack dual-drive foot stator assembly implementation method includes a housing 1, a limit device I2, a bearing 3, a gear 4, a rotary table 5, a packaging plate 6, a rack 7, Limiting device II8, stator 9, baffle plate 10 and package shell 11.

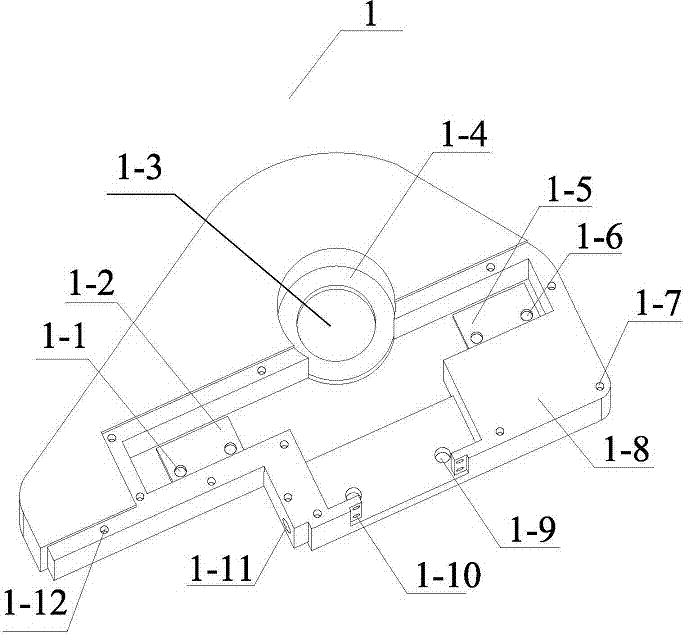

[0058]The housing 1 includes threaded holes I1-1 for the limiting device, mounting bosses I1-2 for the limiting device, bearing mounting surfaces 1-3, gear mounting grooves 1-4, mounting bosses II1-5 for the limiting device, L...

specific Embodiment approach 2

[0077] Specific embodiment 2: The driving method adopts the composite excitation electric signal to realize, the composite excitation electric signal includes the friction control wave and the driving wave, by superimposing the friction control wave on the fast energization stage of the driving wave, the stator is excited in the rapid deformation stage In the state of micro-secondary high-frequency resonance, the frictional resistance between the stator and the rack in the rapid deformation stage is reduced based on the ultrasonic anti-friction effect; the driving wave is a sawtooth wave, and the friction control wave is a sine wave; the period of the sawtooth wave is T 1 , the excitation voltage amplitude is V 1 , the symmetry is S, and the period of the sine wave is T 2 , the excitation voltage amplitude is V 2 , the period ratio of the sawtooth wave to the sine wave is T 1 / T 2 =100~20000, the excitation voltage amplitude ratio is V 1 / V 2 =2~6.

[0078] Working princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com