Intelligent on-off device for self-block electric heating incremental forming heating circuit

A heating circuit and progressive forming technology, applied in metal processing, forming tools, metal processing equipment, etc., to avoid disadvantages and safety hazards, achieve continuity, and good auxiliary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in more detail below in conjunction with the accompanying drawings.

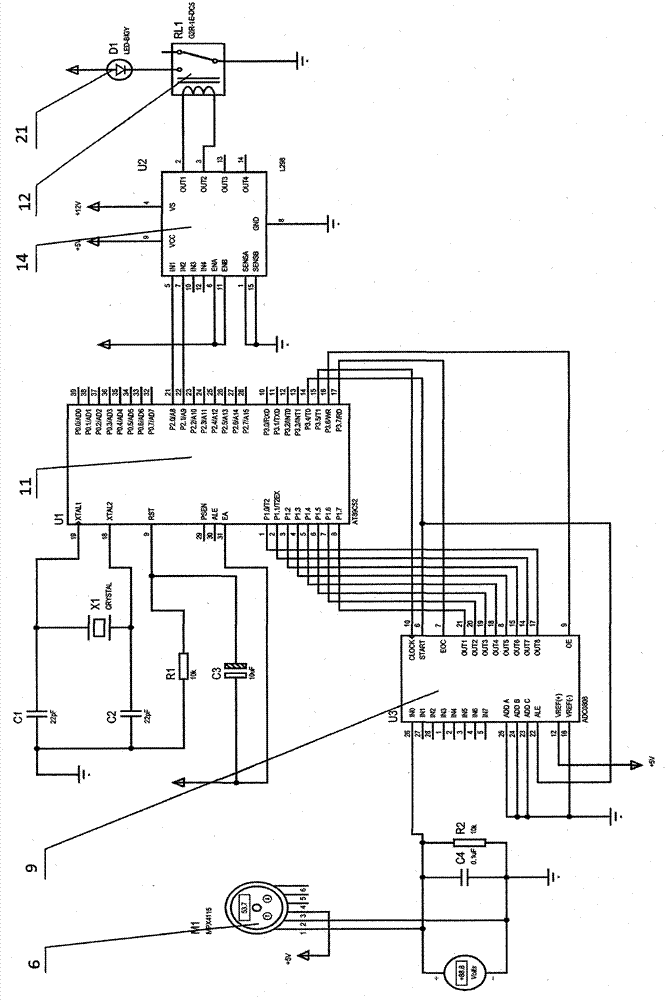

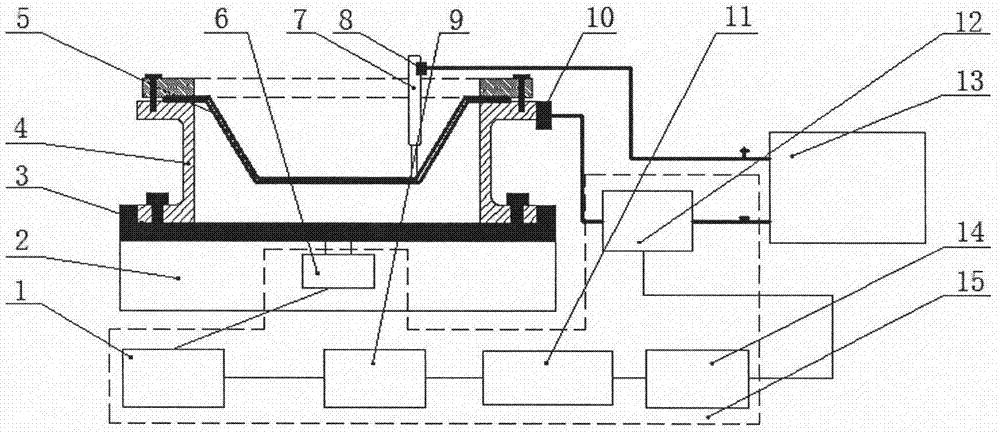

[0013] Such as figure 1 As shown, the self-resistance electric heating progressive forming heating circuit on-off device consists of wooden blocks (2), veneer boards (3), forming devices (4), processing sheets (5), forming tool heads (7), and metal electrodes (8), metal electrode (10), DC power supply (13), control circuit (15) constitute. The control circuit (15) includes a pressure sensor (6), a transmitter (1), an analog-to-digital conversion module ADC0809 (9), an STC89C52 single-chip microcomputer (11), a relay drive module L298 (14), and a relay switch (12). Take out a groove in the shape of the pressure sensor (6) in the block (2), and punch a hole leading to the outside at the side wall of the groove. Afterwards, put the pressure sensor (6) into the groove in the middle of the wooden block (2), and put the signal output line into the punched hole. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com