Pearl cotton board compound machine

A technology of pearl cotton board and composite machine, which is applied in the direction of flat products, household appliances, and other household appliances, which can solve the problems of lower production efficiency, low heat energy utilization rate, and inability to achieve energy saving effects, so as to improve heating efficiency and prevent damage or deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

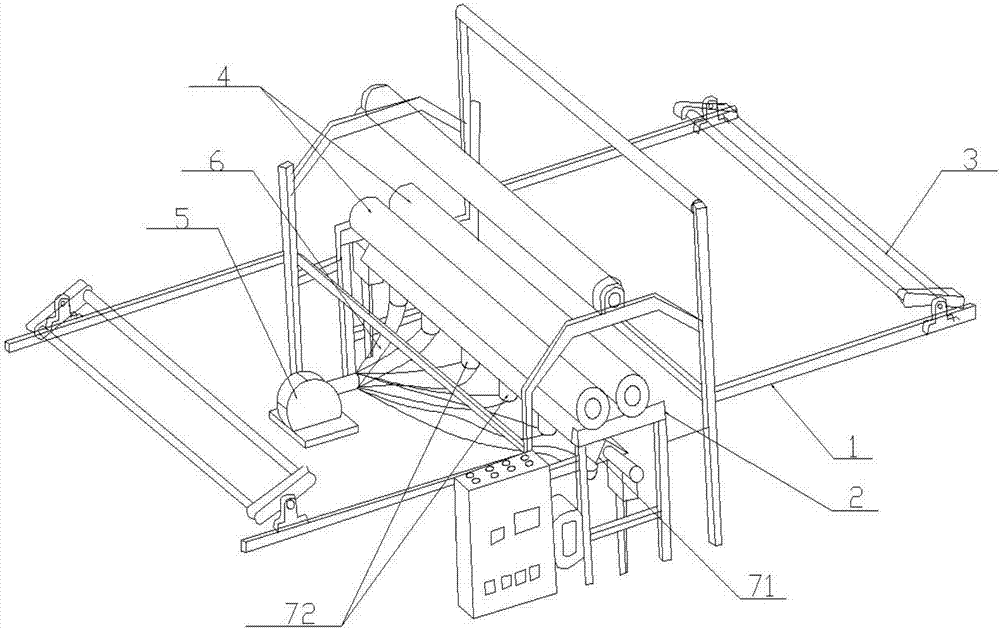

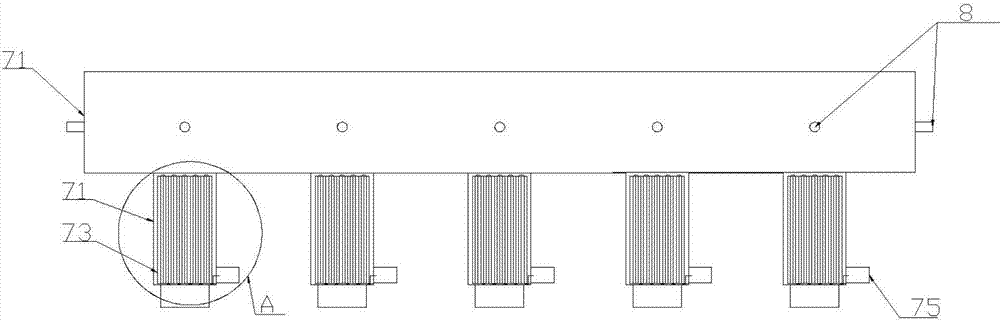

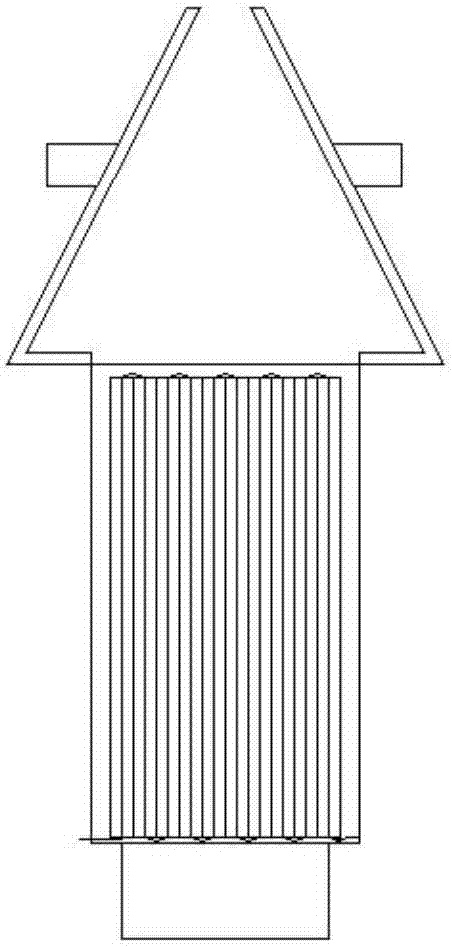

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, a pearl cotton board composite machine, comprising a frame 1, the frame 1 is provided with a fixing frame 2 for clamping the composite pearl cotton board, and the fixing frame 2 both sides are provided with an adjusting frame 3 for winding the pearl cotton board, fixed The middle part of frame 2 is connected with a heating composite mechanism, which includes two pressure rollers 4 arranged in parallel in the middle of the fixed frame and a heating device arranged below the two pressure rollers. The heating device consists of a blower 5, a heating element and a pipeline 6. The heating element Connected with the blower 5 through the pipe 6, the heating element includes a heat collecting pipe 71 and a connecting pipe 72, the heat collecting pipe 71 is erected on the frame 1, and is located directly below the two pressure rollers, and the connecting pipes 72 are equally spaced on the heat collecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com