Safety cock of hydraulic machine

A safety bolt, hydraulic press technology, applied in the direction of presses, punching machines, mechanical equipment, etc., can solve the problems of inability to adjust the height of the bolt body according to the actual situation, damage to the mold and the safety bolt body, and easy damage to the mold, so as to avoid hard contact. , High applicability, the effect of preventing collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

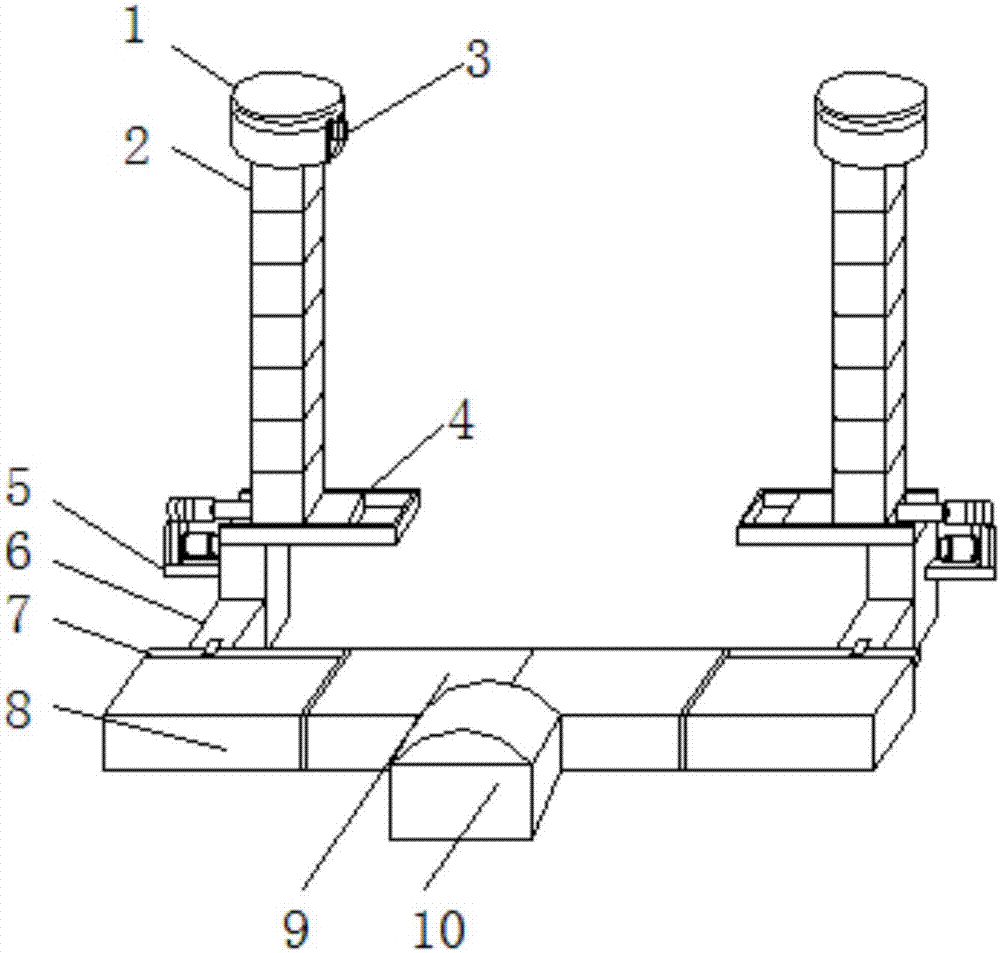

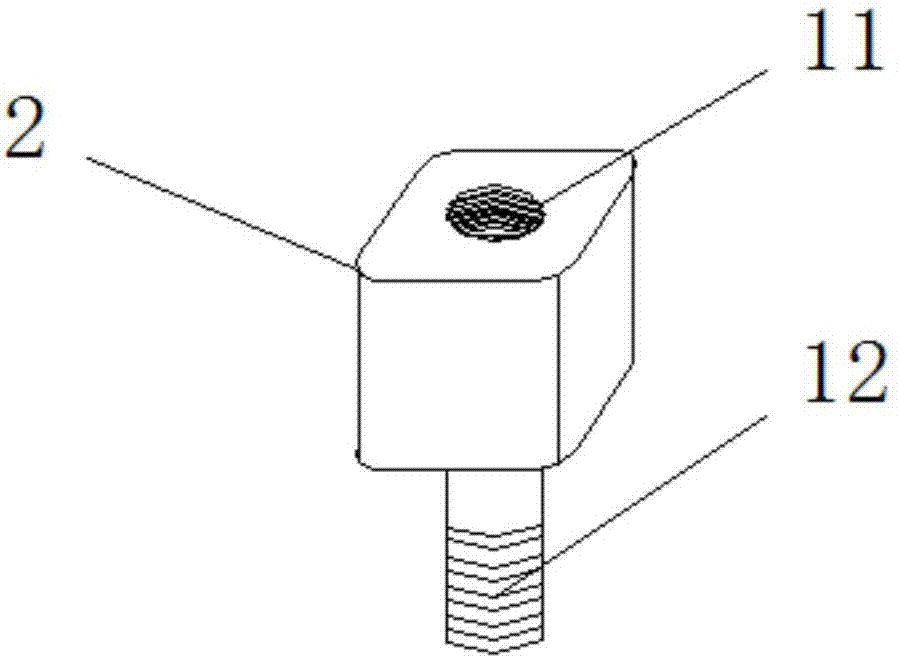

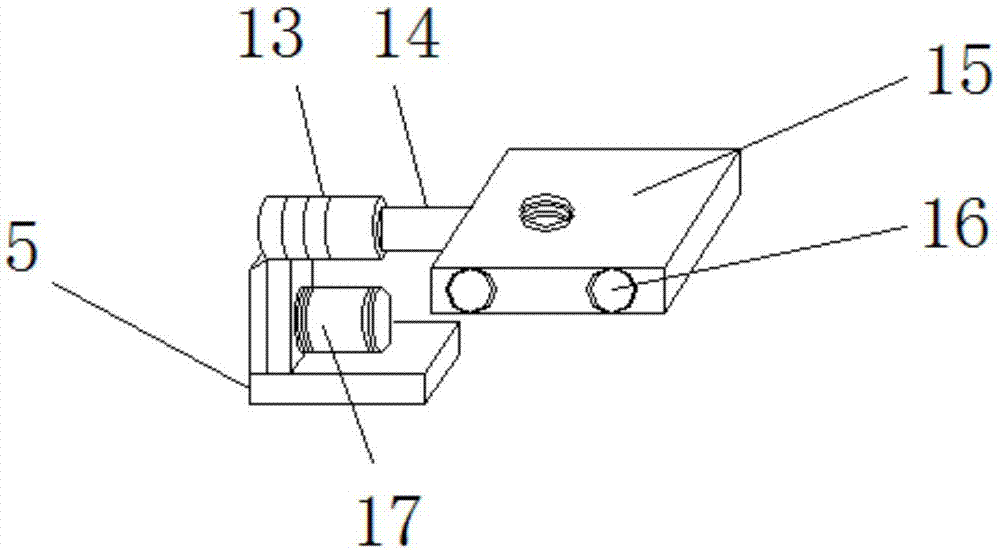

[0020] like Figure 1-3 As shown, a safety bolt for a hydraulic machine comprises a main rod 9, a telescopic square rod 8 is sleeved on both sides of the main rod 9, and a controller 10 is bolted to the front middle part of the main rod 9, and the telescopic square rod The back side of 8 is provided with variable-distance slide rail 7, and the middle part of described variable-distance slide rail 7 is slidably connected with support 6, and the top of described support 6 is bolted with groove box 4, and the inside of described groove box 4 slides through pulley 16 A push rod mechanism 5 is connected, and the middle part of the upper surface of the push rod mechanism 5 is threadedly connected with a plug 2 , the top of the plug 2 is provided with a threaded hole 11 , and the bottom end of the plug 2 is embedded with a bolt 12 , the top of the plug 2 is threaded with a cushion block 1, the inner wall of the cushion block 1 is bolted with an infrared sensor 3, the middle part of t...

Embodiment 2

[0027] A hydraulic machine safety bolt, comprising a main rod (9), characterized in that: telescopic square rods (8) are sleeved on both sides of the main rod (9), and the telescopic square rods (8) are arranged in multiple sections, The front middle part of the main rod (9) is bolted with a controller (10), and the outermost section arranged on the back side of the telescopic square rod (8) has a distance-changing slide rail (7). The middle part of the slide rail (7) is slidably connected with a bracket (6), and the top end of the bracket (6) is bolted with a tank box (4), and the tank box (4) faces one side of the extending direction of the square bar (8) As an opening, the inside of the tank box (4) is slidably connected with a push rod mechanism (5) through a pulley (16), and the middle part of the upper surface of the push rod mechanism (5) is threadedly connected with a bolt (2). The top of the plug (2) is provided with a threaded hole (11), the bottom of the plug (2) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com