Prepacked aggregate concrete decoration concrete stairway and preparation method thereof

A technology for decorating concrete and pre-filling aggregates, applied to stairs, manufacturing tools, ceramic molding machines, etc., can solve the problems of poor finished product effect and complicated operation, and achieve the effects of prolonged service life, good preparation effect and good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The invention discloses a prefilled aggregate decorative concrete staircase, the specific steps are as follows:

[0025] (1) Clean the mold, caulk the seam, apply release oil, install hanging nails, and bind steel bars;

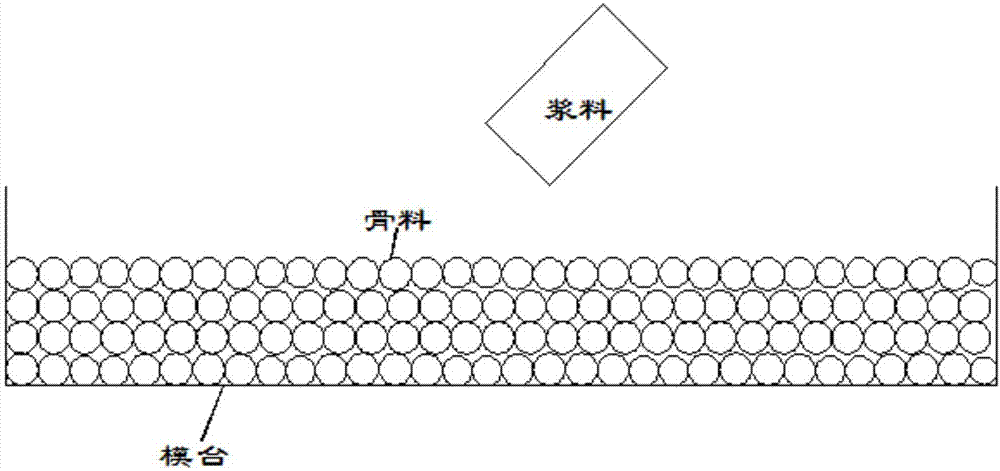

[0026] (2) Spread the stones evenly in the mold to make them accumulate naturally;

[0027] (3) Pour the well-mixed cement slurry into the mold until the cement slurry fills the gaps, covers the stones, and no longer sinks;

[0028] (4) Sprinkle water after removing the formwork, cover the film for maintenance for 4 days, and then polish the surface until the stones are ground out;

[0029] (5), replace the abrasive disc, use 800 mesh, 1000 mesh, 1500 mesh, 2000 mesh, 3000 mesh abrasive disc to grind and polish respectively.

[0030] In the described step (2), during the accumulation of stones, the upper surface of the stones will be piled up smoothly to avoid heaping.

[0031] In the step (3), during the process of pouring the cement slurry into th...

Embodiment 2

[0036] The invention discloses a prefilled aggregate decorative concrete staircase, the specific steps are as follows:

[0037] (1) Clean the mold, caulk the seam, apply release oil, install hanging nails, and bind steel bars;

[0038] (2) Spread the stones evenly in the mold to make them accumulate naturally;

[0039] (3) Pour the well-mixed cement slurry into the mold until the cement slurry fills the gaps, covers the stones, and no longer sinks;

[0040] (4) Sprinkle water after demoulding, cover with film and maintain for 3 days, and then polish the surface until the stones are removed;

[0041] (5) Replace the grinding disc and use a 1000-mesh grinding disc for grinding and polishing.

[0042] In the described step (2), during the accumulation of stones, the upper surface of the stones will be piled up smoothly to avoid heaping.

[0043] In the step (3), during the process of pouring the cement slurry into the mold, the mold is opened to vibrate to assist the flow of t...

Embodiment 3

[0048] The invention discloses a prefilled aggregate decorative concrete staircase, the specific steps are as follows:

[0049] (1) Clean the mold, caulk the seam, apply release oil, install hanging nails, and bind steel bars;

[0050] (2) Spread the stones evenly in the mold to make them accumulate naturally;

[0051] (3) Pour the well-mixed cement slurry into the mold until the cement slurry fills the gaps, covers the stones, and no longer sinks;

[0052] (4) Sprinkle water after removing the formwork, cover the film for maintenance for 5 days, and then polish the surface until the stones are ground out;

[0053] (5) Replace the grinding disc and use a 900-mesh grinding disc for grinding and polishing.

[0054] In the described step (2), during the accumulation of stones, the upper surface of the stones will be piled up smoothly to avoid heaping.

[0055] In the step (3), during the process of pouring the cement slurry into the mold, the mold is opened to vibrate to assis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com