Separated-type tunnel steel arch mounting device

An installation device and steel arch technology, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve problems affecting measurement, drilling, and bolt installation, etc., to reduce the risk of arch installation, reduce the number of workers, and reduce the cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Further detailed explanation through specific implementation mode below:

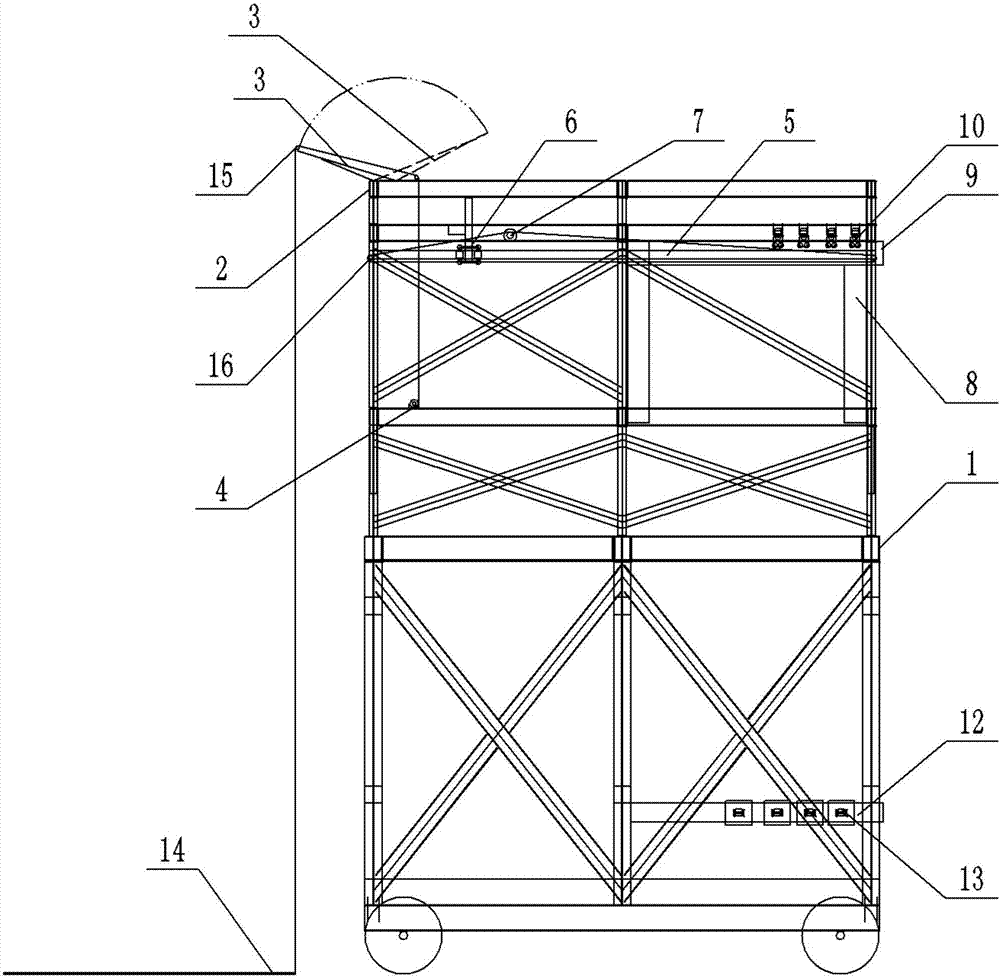

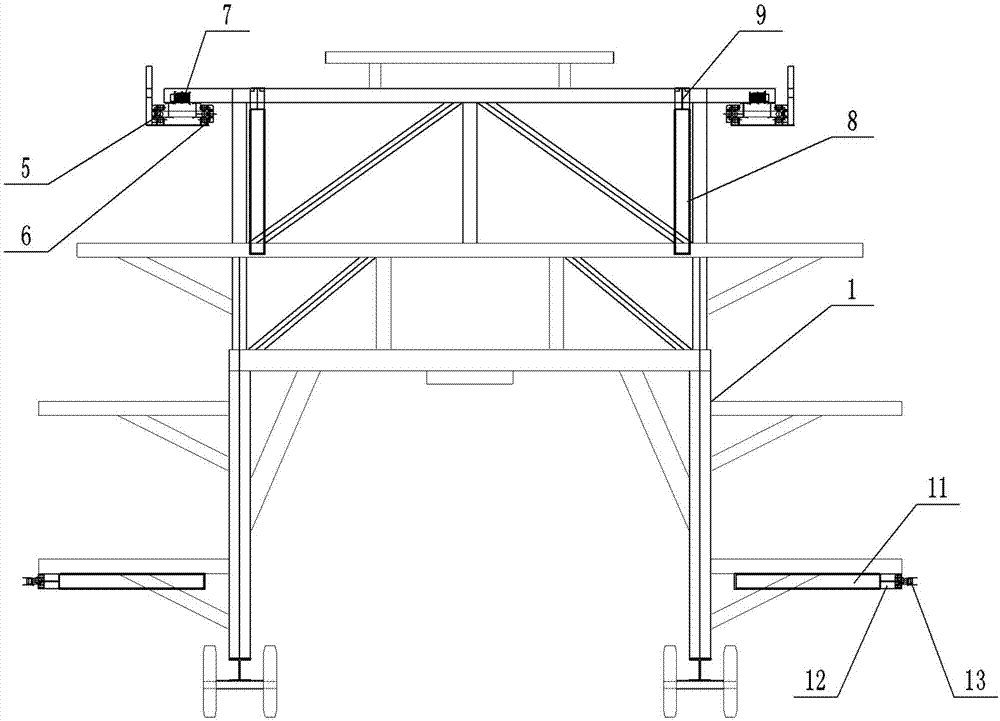

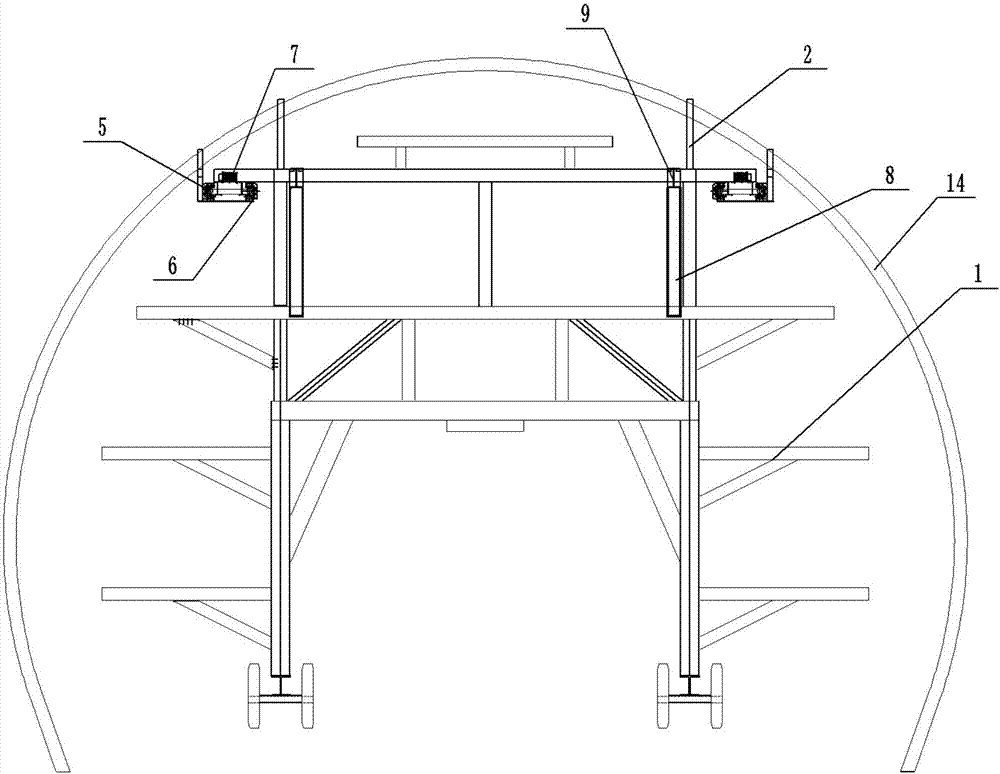

[0029] The reference signs in the accompanying drawings of the description include: excavation trolley 1, first arch lifting member 2, lever 3, first winch 4, round pipe track 5, first translation trolley 6, second winch 7, the first The second arch jacking part 8, the first arch ejection rod 9, the second translation trolley 10, the third arch jacking part 11, the second arch ejection rod 12, the third translation trolley 13, the arch 14 , the first fixed pulley 15, the second fixed pulley 16.

[0030] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown:

[0031]Separate tunnel steel arch installation device, including excavation trolley 1, anchor mesh hoist installed at the end of excavation trolley 1 near the opening, arch lifting mechanism, and installed under the side wings on both sides of the top floor of excavation trolley 1 The arch tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com