Combustor for gas stove

A burner and gas stove technology, which is applied in the field of gas stoves, can solve problems such as hindering the improvement of burner combustion efficiency, reducing yield, and reducing combustion efficiency, and achieves the effect of facilitating flow, replenishment, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

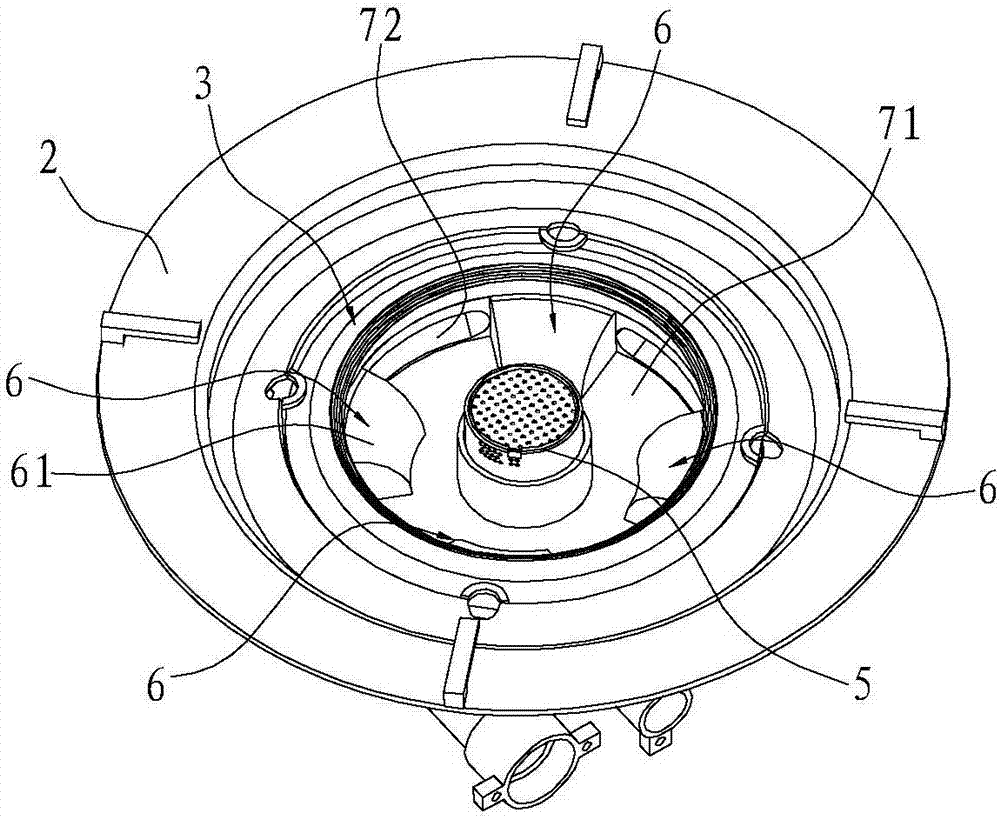

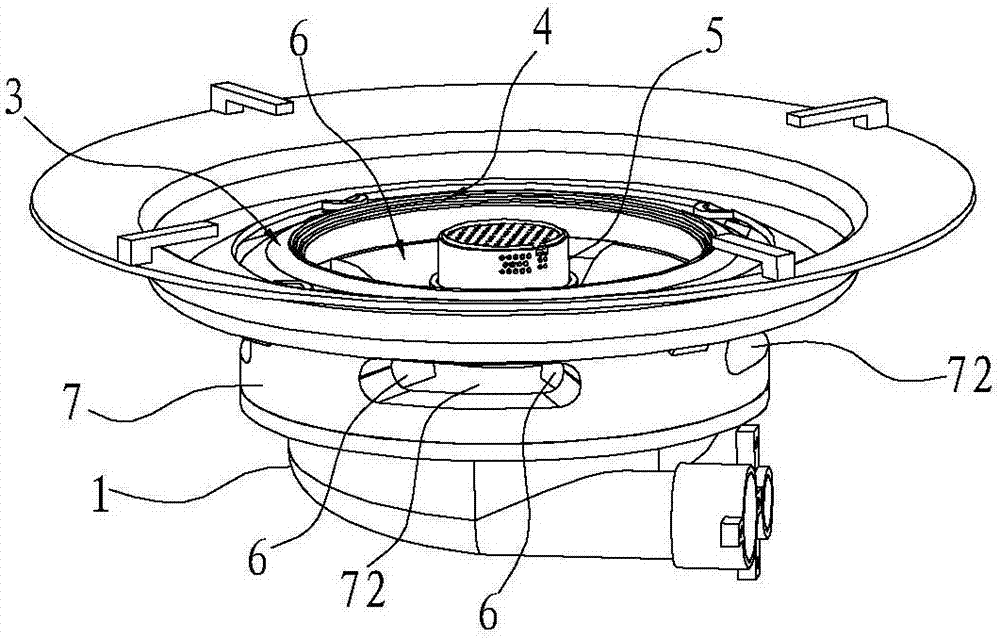

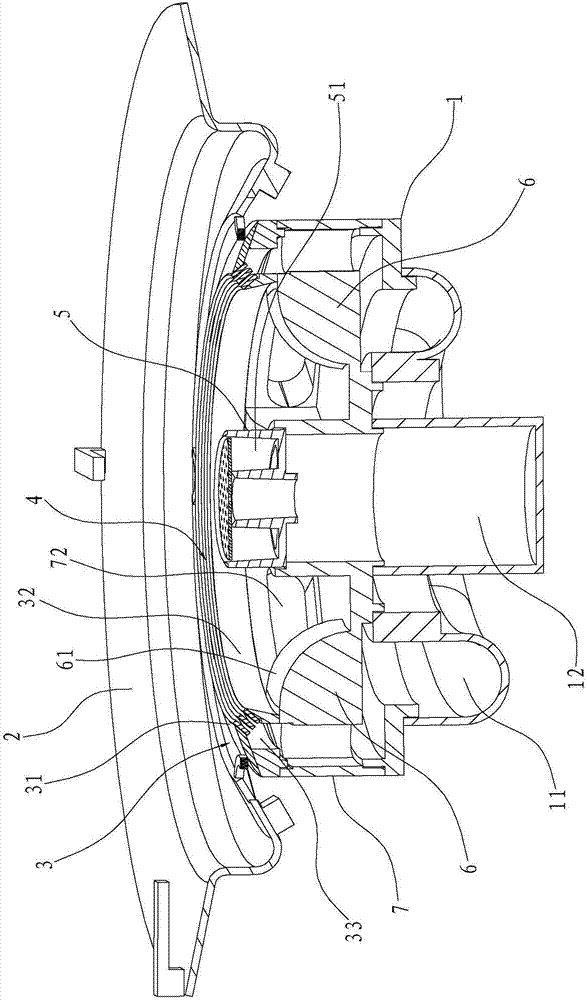

[0032] Such as Figure 7 and Figure 8 As shown, the difference from Embodiment 1 is that the turbulent body 6 in this embodiment is in the form of a sheet and is two pieces, the longitudinal section of each turbulent body 6 is arc-shaped, and the upper end of each turbulent body 6 is fixed to the lower end of the outer ring wall , and its lower end is fixed on the bottom surface of the annular chamber 71. Further, the outer side of each disruptor 6 constitutes the above-mentioned first side 61 , and the radian of the first side 61 is R5˜R200 (preferably R90).

Embodiment 3

[0034] Such as Figure 9 and Figure 11 As shown, different from Embodiment 2, in this embodiment, the longitudinal section of the installation port 30 increases evenly from the inside to the outside, that is, the installation port 30 is flared from the inside to the outside, so that the fire outlet can be effectively adjusted. The gas velocity at the place can effectively avoid the phenomenon of leaving the flame and tempering.

Embodiment 4

[0036] Such as Figure 10 and Figure 12 As shown, the difference from Embodiment 2 is that in this embodiment, the longitudinal section of the installation port 30 becomes smaller evenly from the inside to the outside, that is, the installation port 30 is in the shape of a neck from the inside to the outside, thereby speeding up the fire outlet. The speed of the gas increases the power of the gas, which in turn drives the power of the air at the fire outlet, making the entire combustion more complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com