Optical fiber main distribution frame

A main distribution frame and optical fiber technology, applied in light guides, optics, optical components, etc., can solve problems such as low cable fixing efficiency and chaotic management of fiber jumpers, and achieve the effects of reducing detection difficulty, facilitating later maintenance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

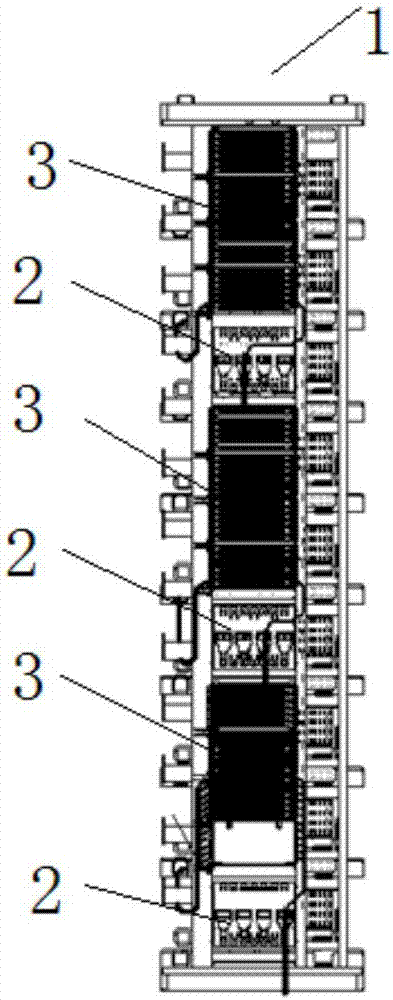

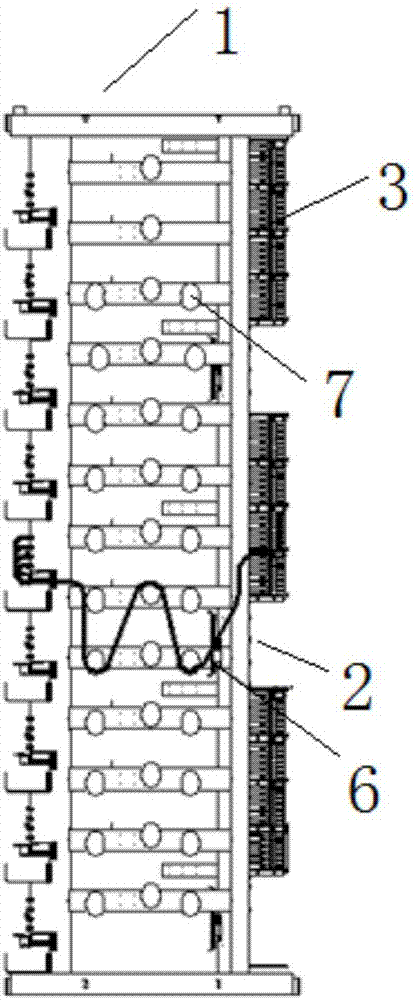

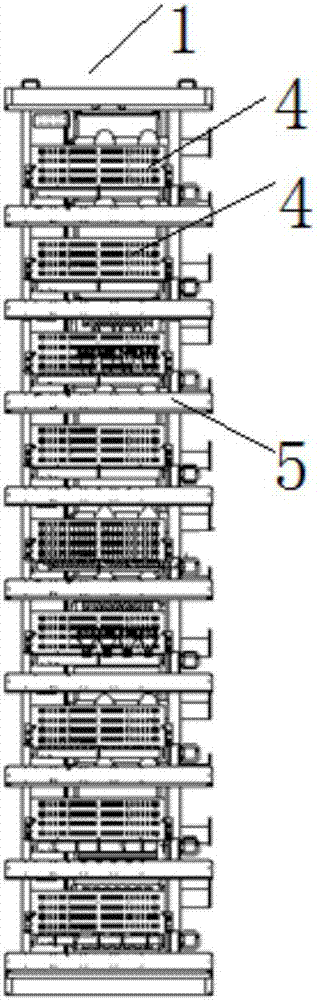

[0024] figure 1 It is the front view of the overall structure schematic diagram of the present invention, figure 2 It is the rear view of the overall structure schematic diagram of the present invention, image 3 It is the left view of the overall structure schematic diagram of the present invention. Such as Figure 1-3 As shown, the optical fiber main distribution frame provided by the present invention includes: a frame body 1, the front side of which is the line side; the back side is the equipment side; the left and right sides of the frame body are storage areas for fiber jumpers.

[0025] The front of the frame body 1 includes a plurality of optical cable stripping devices 2 and a plurality of integrated fusion modules 3, and the optical cable stripping devices 2 and the integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com