Machine-vision-based workpiece detection method and system

A workpiece detection and machine vision technology, which is applied to computer parts, instruments, measuring devices, etc., can solve the problems of high requirements on workpiece angles and positions, unsatisfactory realization, and unsatisfactory process effects, and achieves low cost and good quality. Detection effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

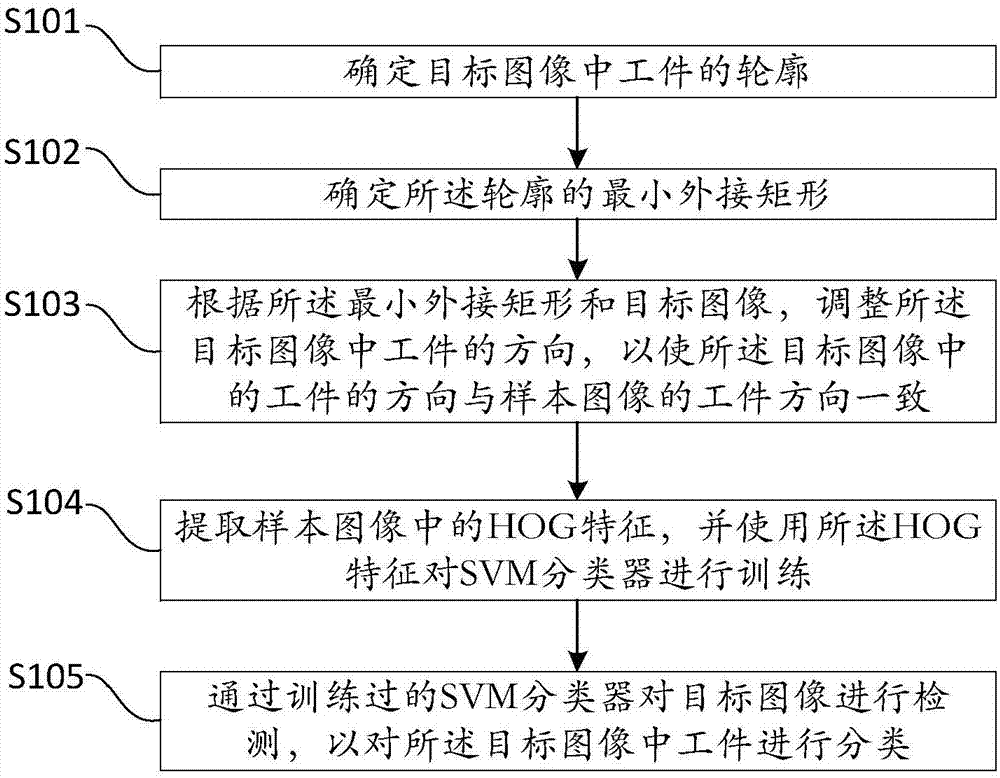

[0060] This embodiment provides a workpiece detection method based on machine vision, the flow chart of which is as follows figure 1 As shown, the details are as follows:

[0061] Step S101, determining the contour of the workpiece in the target image.

[0062] Among them, the target image comes from the camera device of the industrial robot. The imaging process of the imaging device is continuous; therefore, in the present invention, the process of processing the target image is also continuous.

[0063] The profile to which the present invention relates includes the profile of the outermost edge.

[0064] Obtain the outline of the outermost edge through the flood fill algorithm. The flood fill method, also known as the seed fill method, has many applications in graphics. The paint bucket tool of the "Paint" software under Windows is based on this algorithm. When you want to color a closed area or change the color in a closed area, the program automatically selects the are...

Embodiment 2

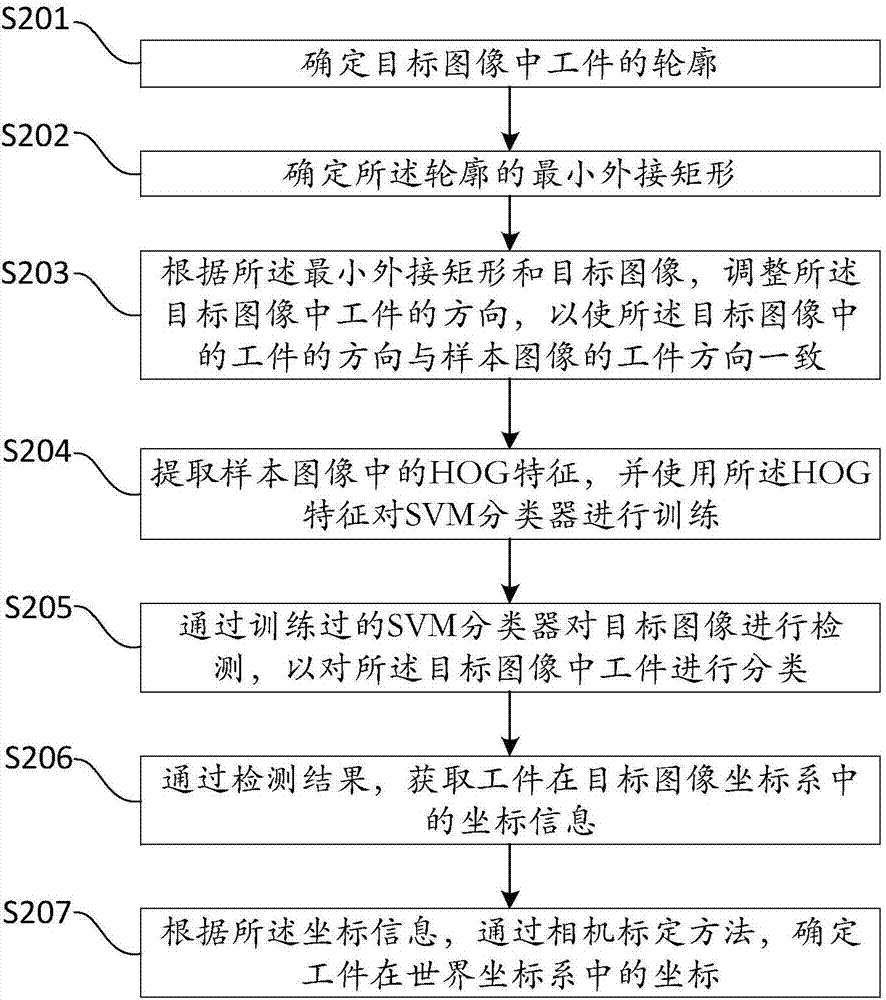

[0086] This embodiment provides a workpiece detection method based on machine vision, the flow chart of which is as follows figure 2 As shown, the details are as follows:

[0087] Step S201, determining the contour of the workpiece in the target image.

[0088] Step S202, determining the smallest circumscribed rectangle of the outline.

[0089] Step S203, adjusting the orientation of the workpiece in the target image according to the minimum circumscribed rectangle and the target image, so that the orientation of the workpiece in the target image is consistent with the orientation of the workpiece in the sample image.

[0090] Step S204, extracting HOG features in the sample image, and using the HOG features to train the SVM classifier.

[0091] In step S205, the target image is detected by the trained SVM classifier, so as to classify the artifacts in the target image.

[0092] Since steps S201 to S205 have been described in detail in Embodiment 1, details will not be rep...

Embodiment 3

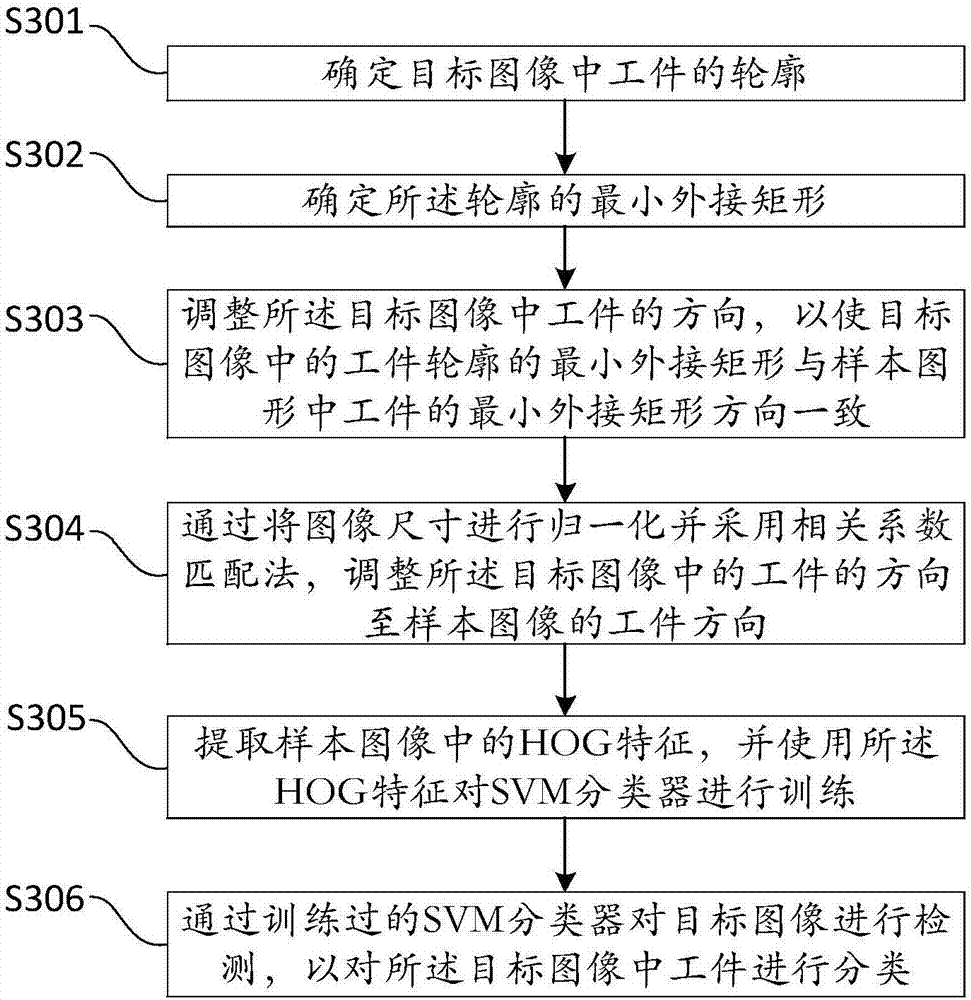

[0114] This embodiment provides a workpiece detection method based on machine vision, the flow chart of which is as follows image 3 , as detailed below:

[0115] Step S301, determining the contour of the workpiece in the target image.

[0116] Step S302, determining the smallest circumscribed rectangle of the outline.

[0117] Step S303 , adjusting the direction of the workpiece in the target image, so that the direction of the smallest circumscribed rectangle of the workpiece contour in the target image is consistent with the direction of the smallest circumscribed rectangle of the workpiece in the sample graphic.

[0118] Rotate the workpiece in the target image around the center of the rectangle until the direction of the smallest circumscribing rectangle of the workpiece outline in the target image is consistent with the direction of the smallest circumscribing rectangle of the workpiece in the sample graphic.

[0119] Since the rectangle is a centrally symmetrical figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com