A preparation method of ultra-thin-walled multi-level porous carbon/polyaniline supercapacitor electrode material

A technology of supercapacitor and porous carbon, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of affecting the electrochemical performance of porous carbon, low utilization rate of internal holes, poor conductivity, etc. Friendly, improve the agglomeration phenomenon, improve the effect of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

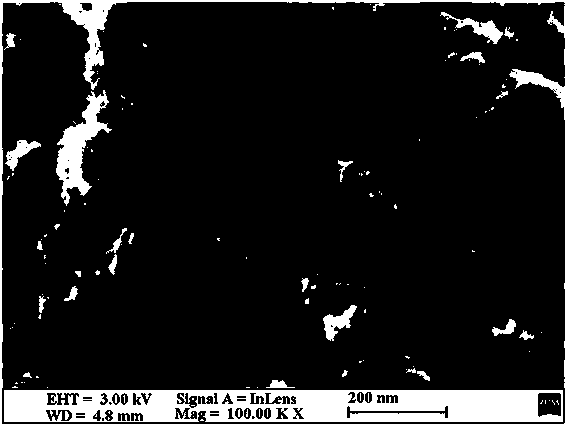

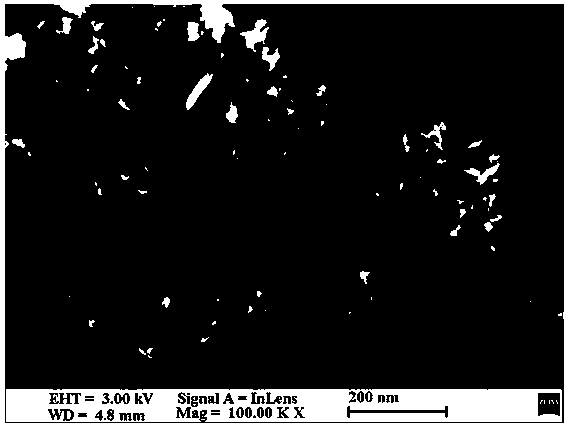

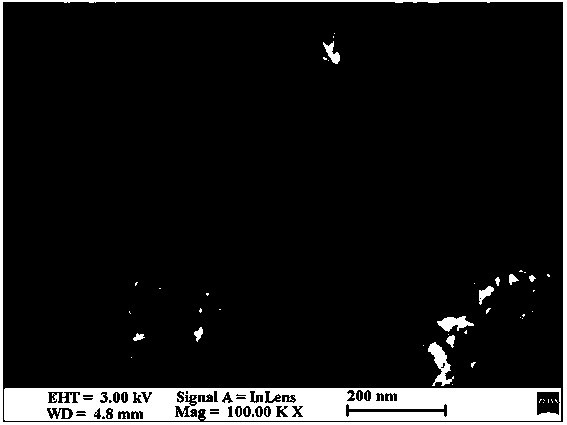

Image

Examples

Embodiment 1

[0031] A preparation method of an ultra-thin-walled multi-level porous carbon / polyaniline composite, comprising the steps of:

[0032] 1) Preparation of ultra-thin-walled hierarchical porous carbon

[0033] The coal tar pitch and aluminum sulfate are weighed and mixed according to the mass ratio of 1:3, and then styrene is added, and the mass ratio of the mixture to styrene is 9:1. The two were mixed uniformly by mechanical stirring, and nitrogen gas was introduced, the stirring temperature was 150° C., and the stirring time was 2 h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven (1.0×10 -1 Pa) Dry for 8h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, heated to 700°C at a rate of 10°C / min, kept for 4 hours, cooled to room temperature and taken out for later use.

[0034] 2) Preparation of ultra-thin-walled hierarchical porous carbon / polyaniline composites

[0...

Embodiment 2

[0038] A preparation method of an ultra-thin-walled multi-level porous carbon / polyaniline composite, comprising the steps of:

[0039] 1) Preparation of ultra-thin-walled hierarchical porous carbon

[0040] The petroleum pitch and aluminum carbonate were weighed and mixed according to the mass ratio of 1:1.5, and then styrene was added, and the mass ratio of the mixture to styrene was 7:3. The two were mixed uniformly by mechanical stirring, and nitrogen gas was introduced, the stirring temperature was 120° C., and the stirring time was 2 h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven (1.0×10 -1 Pa) Dry for 8h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, heated to 1000°C at a rate of 10°C / min, kept for 2 hours, cooled to room temperature and taken out for use.

[0041] 2) Preparation of ultra-thin-walled hierarchical porous carbon / polyaniline composites

[...

Embodiment 3

[0045] A preparation method of an ultra-thin-walled multi-level porous carbon / polyaniline composite, comprising the steps of:

[0046] 1) Preparation of ultra-thin-walled hierarchical porous carbon

[0047] The mesophase pitch and aluminum isopropoxide were weighed and mixed according to the mass ratio of 1:2, and then styrene was added, and the mass ratio of the mixture to styrene was 1:1. The two were mixed uniformly by mechanical stirring, and nitrogen gas was introduced, the stirring temperature was 150° C., and the stirring time was 2 h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven (1.0×10 -1 Pa) Dry for 8h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, heated to 800°C at a rate of 10°C / min, kept for 3 hours, cooled to room temperature and taken out for later use.

[0048] 2) Preparation of ultra-thin-walled hierarchical porous carbon / polyaniline composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com