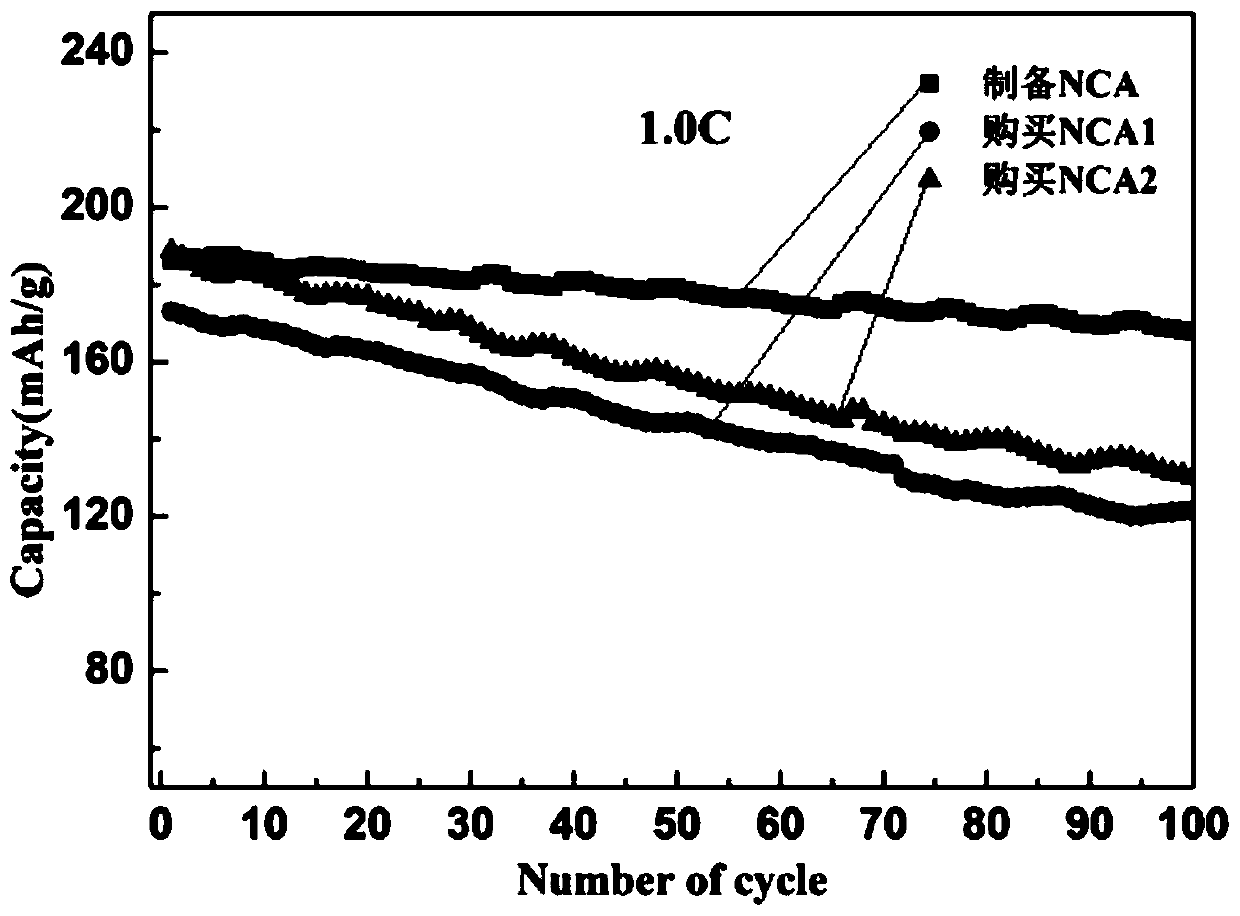

A kind of preparation method suitable for power type lithium ion battery, high cycle stability NCA cathode material

A lithium-ion battery, cycle stability technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult to control NCA morphology, difficult to ensure uniform distribution of elements, etc., to achieve excellent rate and cycle stability , easy to popularize, excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

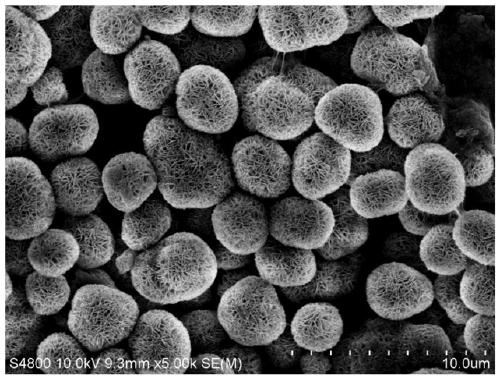

[0032] The preparation of the precursor firstly weighs nickel salt and cobalt salt according to the element ratio of nickel and cobalt 0.8:0.15. Then, the salt solution composed of Ni and Co salt, the alkaline metaaluminate solution composed of metaaluminate and ammonia water, and the sodium hydroxide solution are prepared by co-precipitation titration of the three solutions.

[0033] The metaaluminate is prepared by mixing aluminum salt with sodium hydroxide in an amount 4-5 times that of the aluminum salt.

[0034] The concentration ratio of the ammonia solution to the salt solution is between 1:2-2:1.

[0035] The concentration ratio of the sodium hydroxide solution to the salt solution is between 2:1-4:1.

[0036] For the preparation of the precursor, 2-6L of ultrapure water is used in the base solution, and ammonia water is used to drop the pH to between 10.5-11.5.

[0037] In the preparation of the precursor, during the titration process, the dropping speed of the alka...

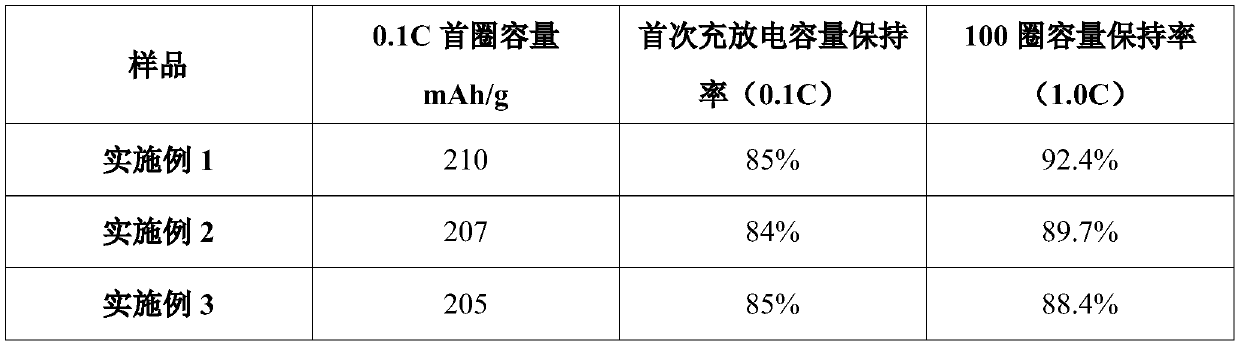

Embodiment 1

[0042] The preparation of the NCA cathode material includes: preparing the NCA precursor by a co-precipitation method, and mixing lithium by a dry method and a wet method.

[0043] The preparation of described NCA precursor, wherein Ni, Co, Al salt all adopt sulfate, ammoniacal liquor usage content (NH 3 ) is 25-28wt% ammonia solution. The titration reaction used an automatic titration reactor, and the rotation speed during the titration process was 600 rap / min.

[0044] In the described mixed lithium method, the lithium source used is LiOH.H 2 O.

[0045] Its specific preparation method is as follows:

[0046](1) First, according to the Ni, Co, Al element ratio 80:15:5, take the sulfate salt with a total mass of 4mol, mix the Ni and Co salts to prepare a salt solution with a concentration of 2mol / L, and weigh 0.9mol Mix NaOH with Al salt to prepare metaaluminate, and add 5.5 mol of ammonia water to the metaaluminate at the same time to prepare a solution with the same vol...

Embodiment 2

[0049] The difference from Example 1 is that

[0050] Ni, Co salt solution, metaaluminate solution, alkali solution concentration are 1mol / L, 1.2mol / L, 2.4mol / L respectively.

[0051] According to the precursor and LiOH.H 2 The O ratio is 1:1.03, and the milling speed is 100rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com