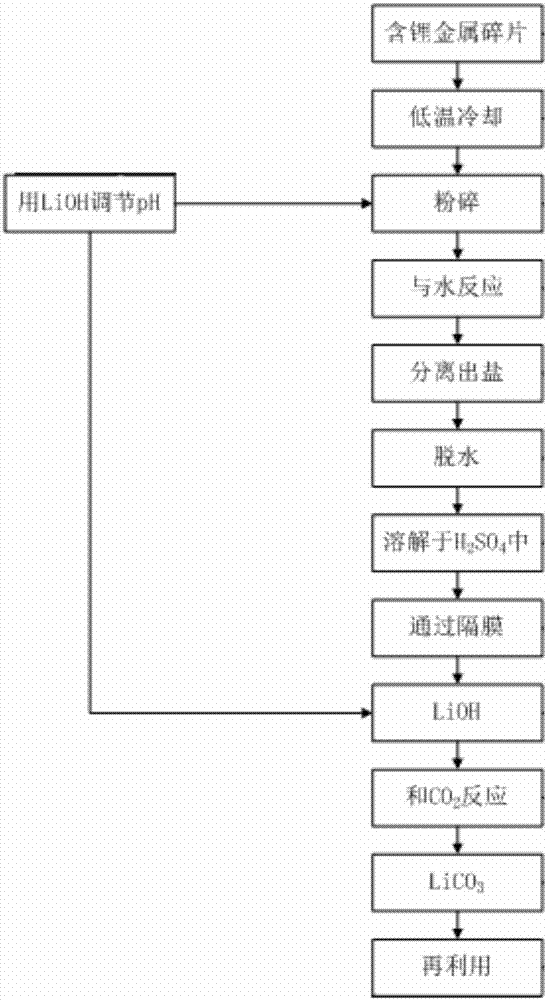

Lithium recycling process

A process, lithium salt technology, applied in the field of lithium recovery and reuse process, can solve the problems of low Li recovery efficiency, lower economic benefits, difficult removal of Na ions, etc., to achieve faster speed, high economic benefits, and good safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Example: Collect waste lithium batteries and uniformly store them in the recycling area. You can choose to discharge the batteries by immersing them in salt water or using an ohmic resistor, and then immerse the batteries in liquid nitrogen to reduce their temperature to minus 320°F, thereby The reactivity of Li is 5-6 orders of magnitude lower than its activity at room temperature. The quality and structure of a battery or battery component determine the time required for it to be fully cooled. Thin lithium metal strips can be fully cooled within a few minutes. A battery of about 1 kg may take several hours, while a lithium battery pack of more than 200 kg must be kept completely immersed for 8 hours, and a sufficient amount of liquid nitrogen needs to be replenished during this time.

[0024] After the battery and its components are fully cooled, they are taken out of the liquid nitrogen and crushed. The crushing operation can be carried out by a hammer mill, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com