Multifunctional full-automatic grooving machine

A fully automatic, slotting machine technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problem of not being able to satisfy vertical and horizontal cutting at the same time, unable to perform mechanical automatic punching, and slotting uniformity Insufficient and other problems, to achieve the effect of eliminating potential safety hazards, convenient installation and maintenance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

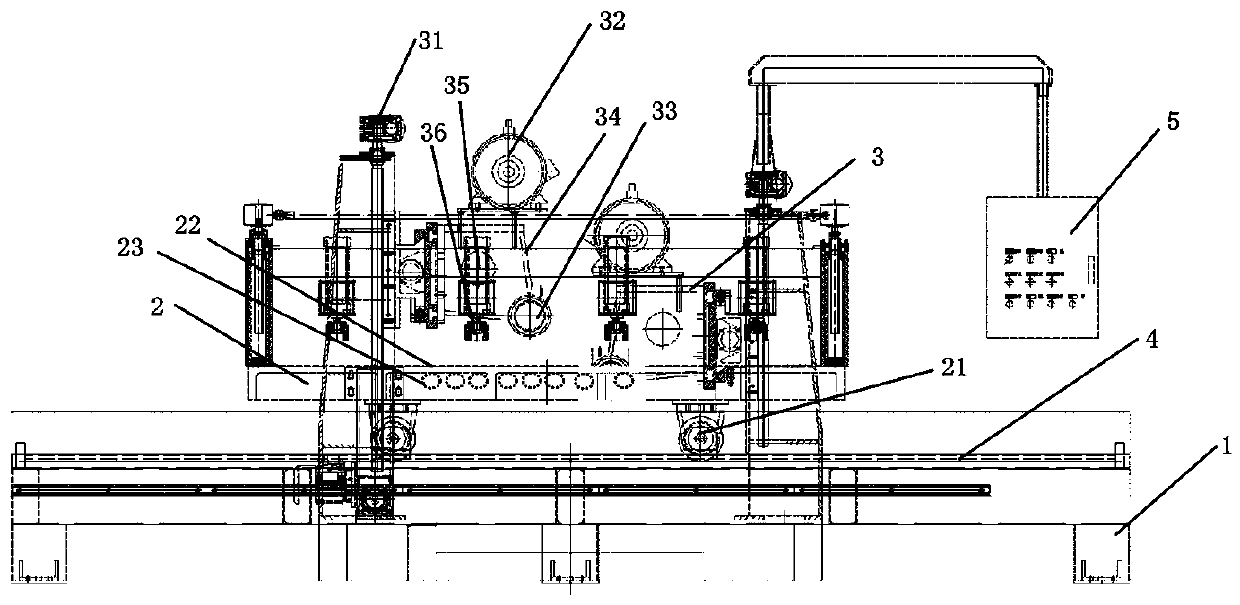

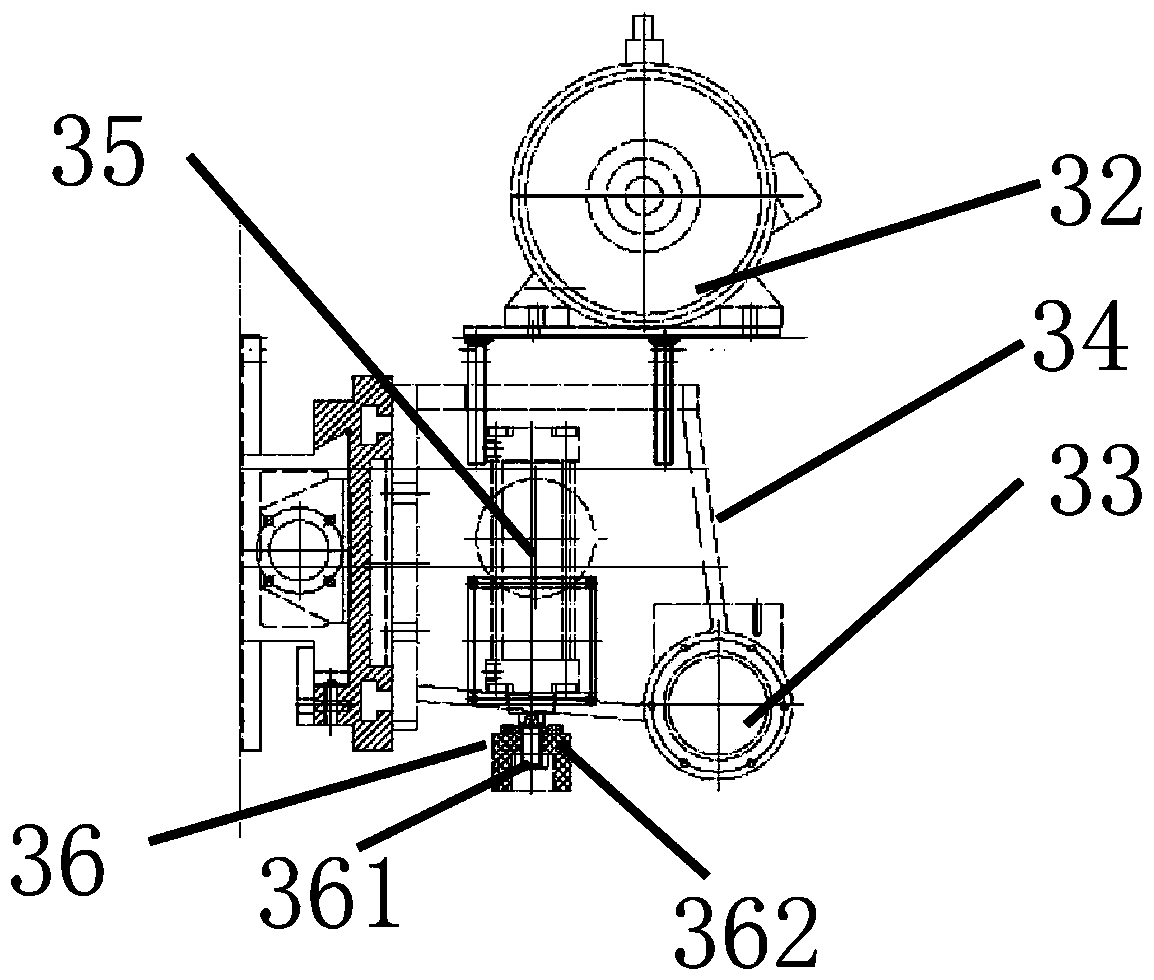

[0018] Such as Figure 1-2 Shown, a kind of multifunctional full-automatic slotting machine comprises frame 1, processing platform 2, slotting device 3, rail device 4 and control device 5, and described rail device 4 is arranged on frame 1, and described The bottom 2 of the processing platform is provided with a slide rail wheel 21, and the slide rail wheel 21 is arranged on the track device 4 for moving and conveying, and the slotting device 3 is respectively fixed above the two ends of the working platform 2 and faces the working surface. The platform 2, the control device 5 is a systematic control device that adopts a numerical control system to respectively control the slotting device 3 to slot the stone, and the processing platform 2 is composed of a side plate 22 and a universal ball bearing 23. The surface of the side plate 22 is provided with a plurality of hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com