Uncoiling process of winding coil material

A technology of process and material roller, which is applied in the field of disposable sanitary products production process, and can solve the problems of long joints and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0022] Embodiments of the invention are:

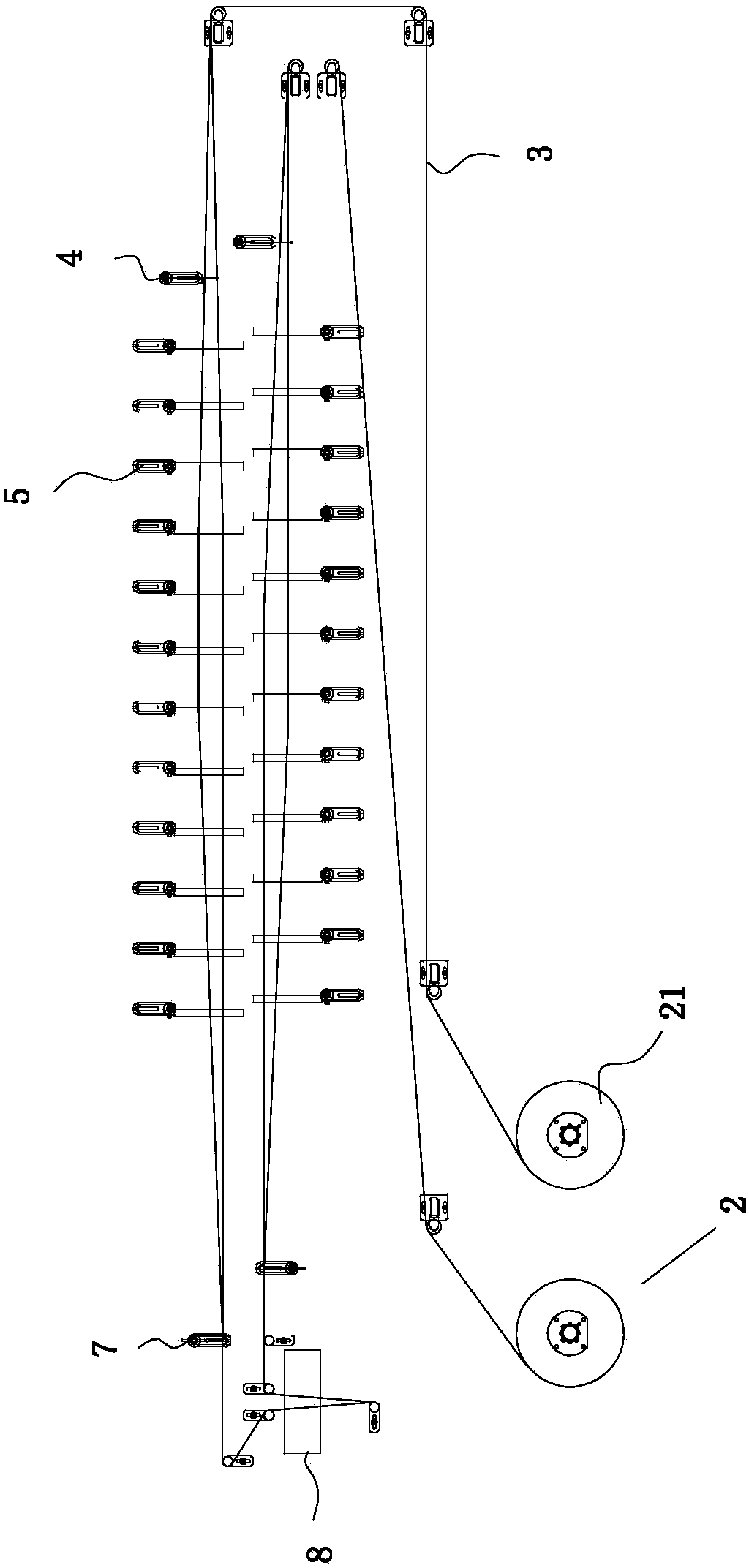

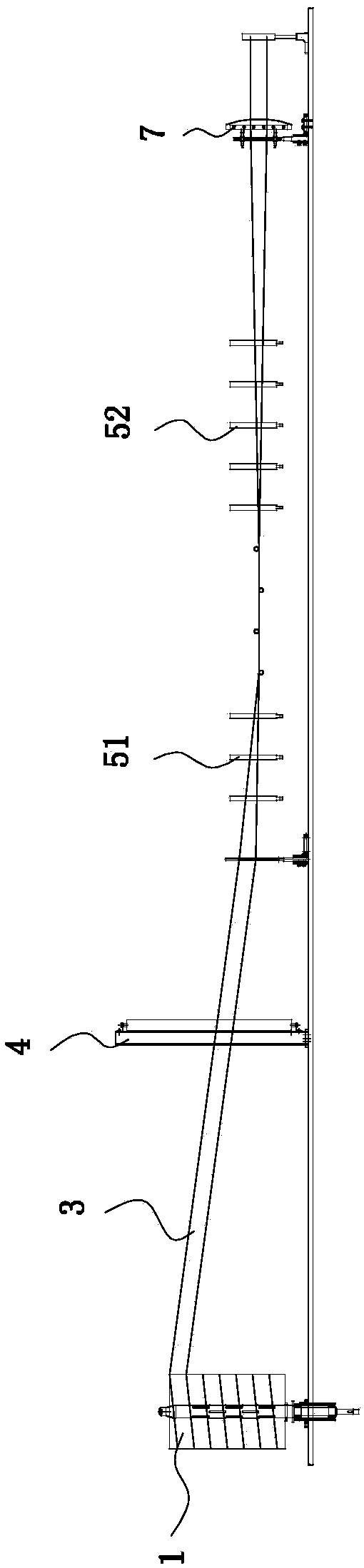

[0023] refer to figure 1 and figure 2 , a kind of decoiling process of winding coil material, its process step is:

[0024] (1) Two volumes of non-woven fabric winding rolls 1 are respectively assembled on the air expansion shafts 21 of the left and right material rollers of the unwinding device 2, and the wound non-woven fabric 3 winding rolls are respectively rotated by the left and right material rollers. Unwinding, the width of the non-woven fabric 3 is 100mm, and the width of the non-woven winding roll 1 is 700mm;

[0025] (2) the non-woven fabric 3 in the discharging carries out the early stage limit respectively by the ring limit device 4, and the limit width of the ring limit device 4 is less than the width of the non-woven winding roll 1;

[0026] (3) The non-woven fabric 3 after the limit posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com