A Segmented Slurry-Water Separation Layered Counterflow Inclined Plate Sedimentation System

A mud-water separation and inclined plate precipitation technology, applied in separation methods, sedimentation separation, sedimentation tanks, etc., can solve the problems of difficulty in maintaining the long-term high efficiency and stability of the inclined plate sedimentation tank, difficulty in obtaining high efficiency and stability, and excessive disturbance of the rising water flow. Achieve long-term high efficiency and stable sludge removal capacity, maintain sludge removal capacity, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

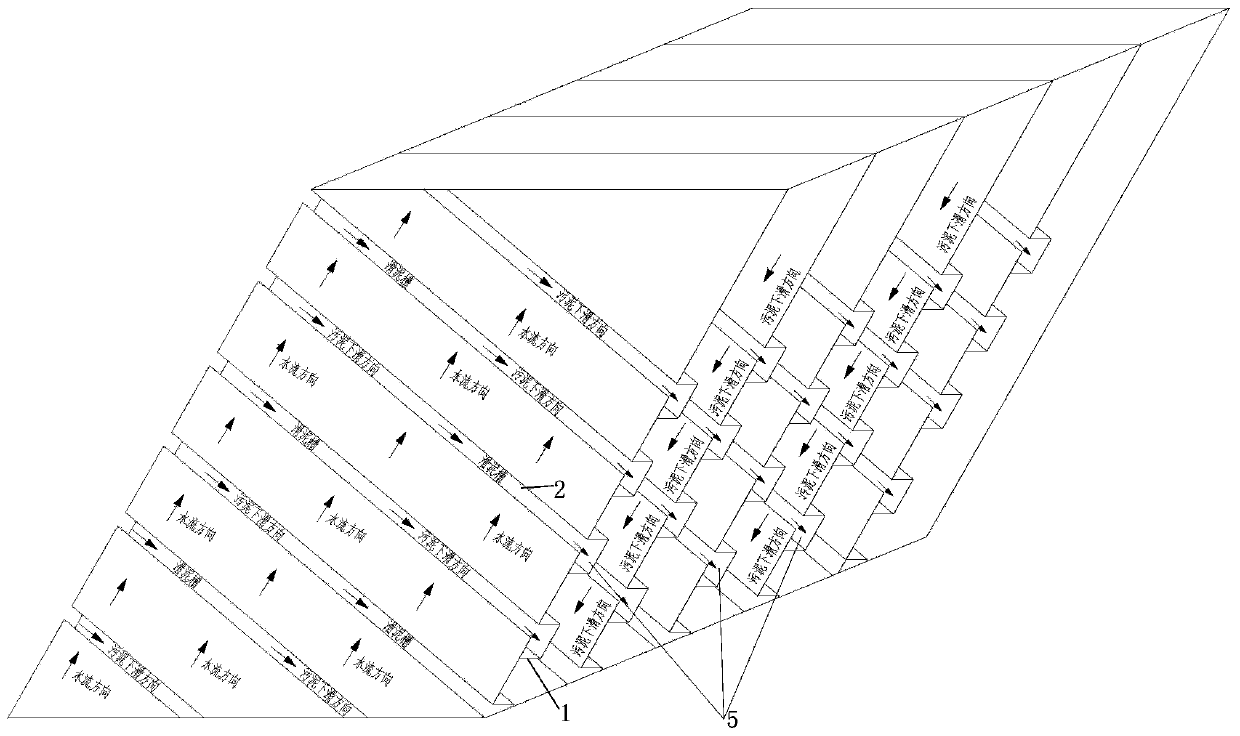

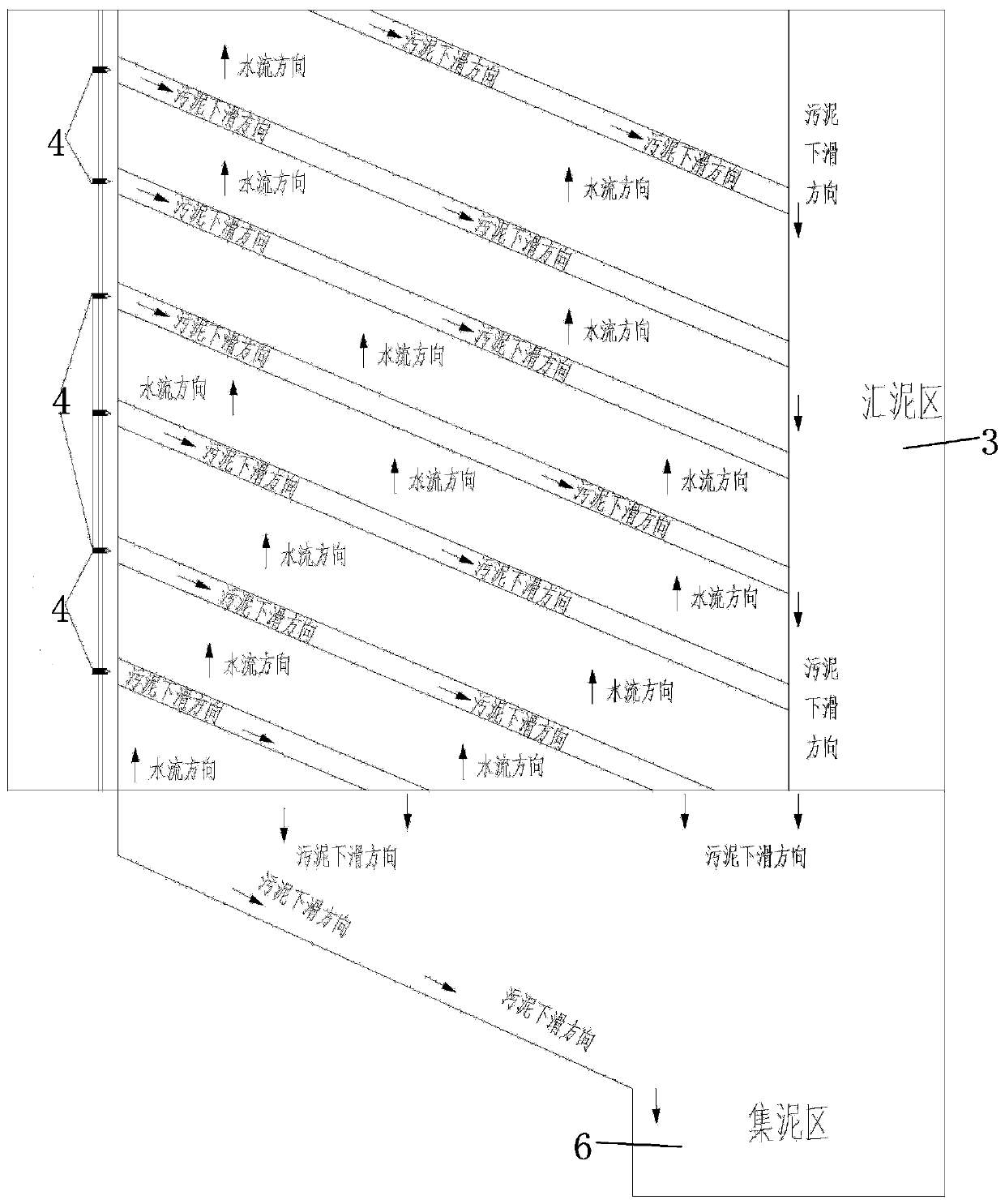

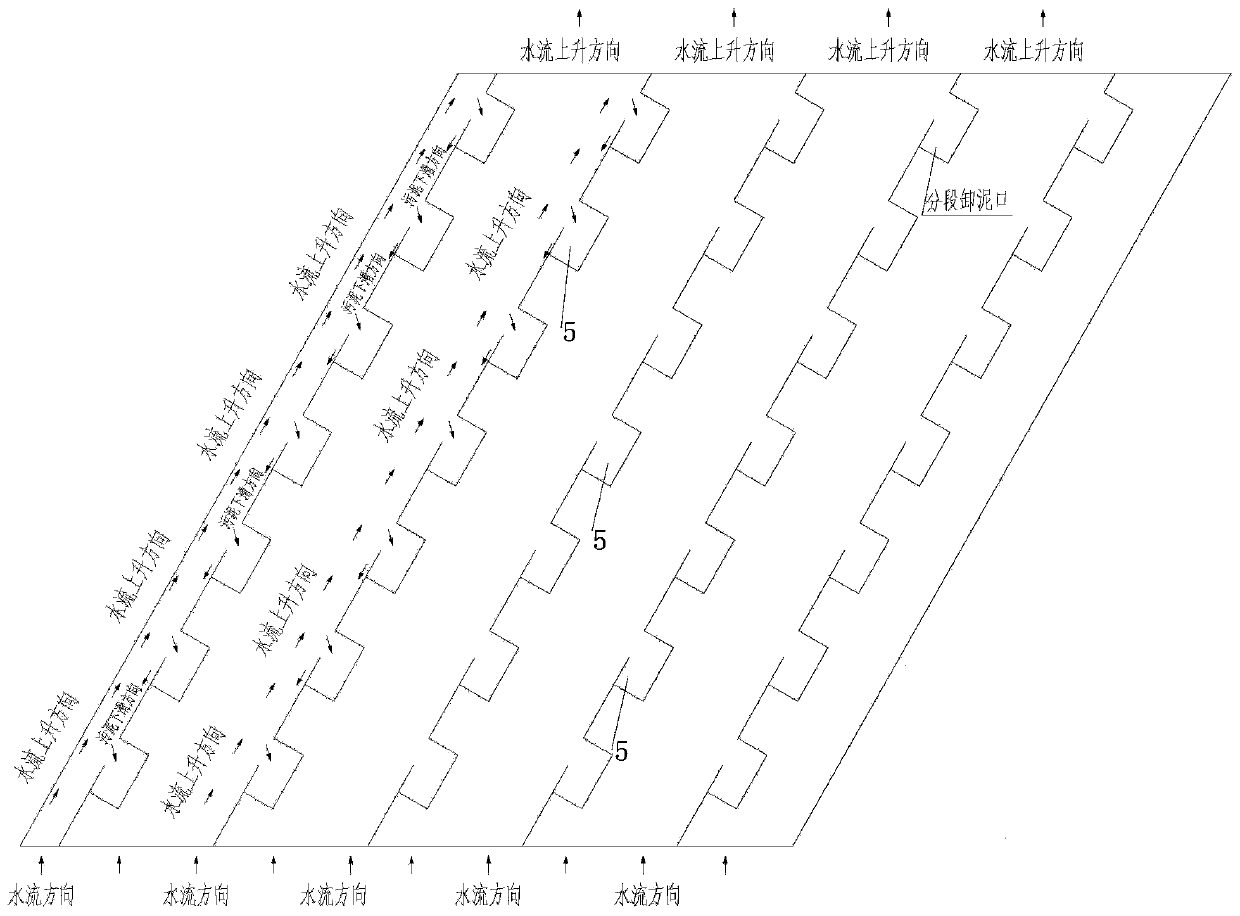

[0034] The invention provides a slanted plate sedimentation system with segmented mud-water separation and layered counterflow, in order to solve the defects of the existing slanted plate sedimentation tank and achieve the purpose of maintaining its long-term, efficient and stable sludge removal.

[0035] The present invention sets a segmented slant plate structure, which greatly shortens the sliding path of the settled sludge, so as to realize the effectiveness of mud-water separation; sets an independent sliding sludge tank, separates the rising water flow and the sludge collection and slides down on different spatial plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com