Sulphur feeder in sodium metabisulfite production

A technology of sodium metabisulfite and additives, applied in the direction of alkali metal sulfite/sulfite, preparation of alkali metal sulfite, chemical instruments and methods, etc., can solve waste of energy, insufficient combustion of sulfur, difficult to control Oxygen intake and other issues, to achieve full combustion and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

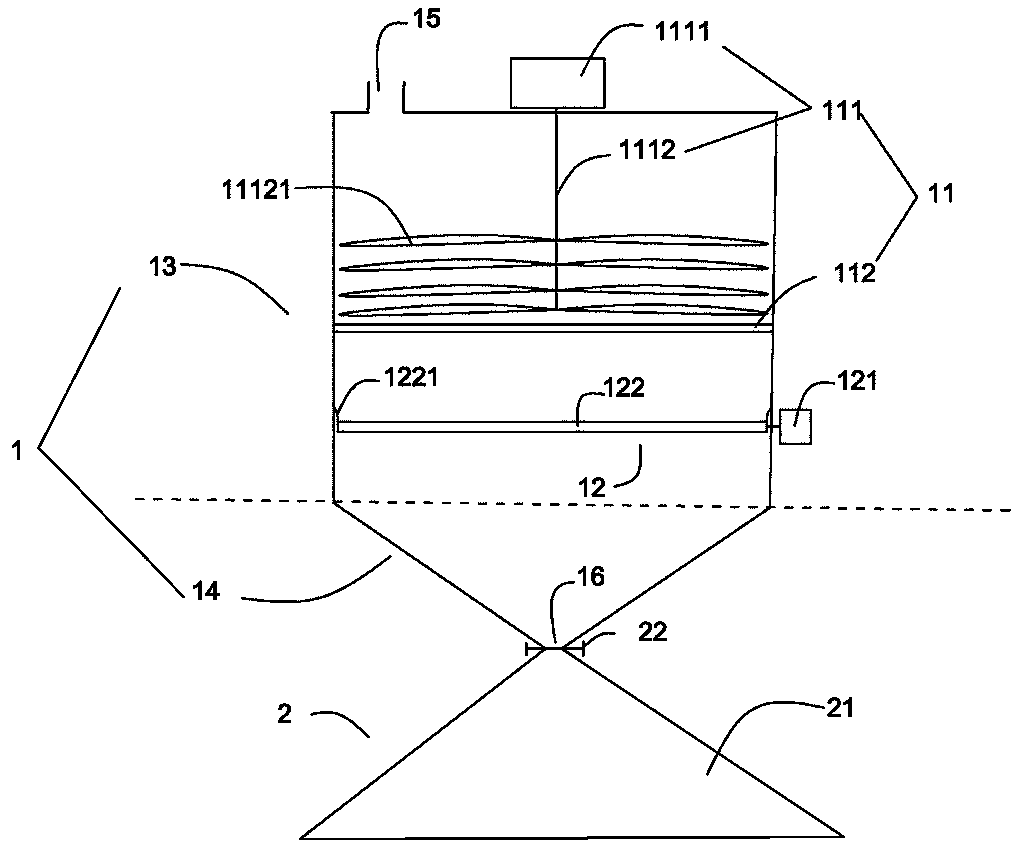

[0028] Such as Figures 1 to 5 The shown sulfur additive in the production of sodium metabisulfite includes a bucket housing 1, a crushing structure 11 arranged in the bucket housing 1, a filtering structure 12 and a discharge structure 2 arranged below the bucket housing 11 . The bucket-type shell can concentrate crushing, filtering, and feeding in one device, which saves production costs and is easy to operate.

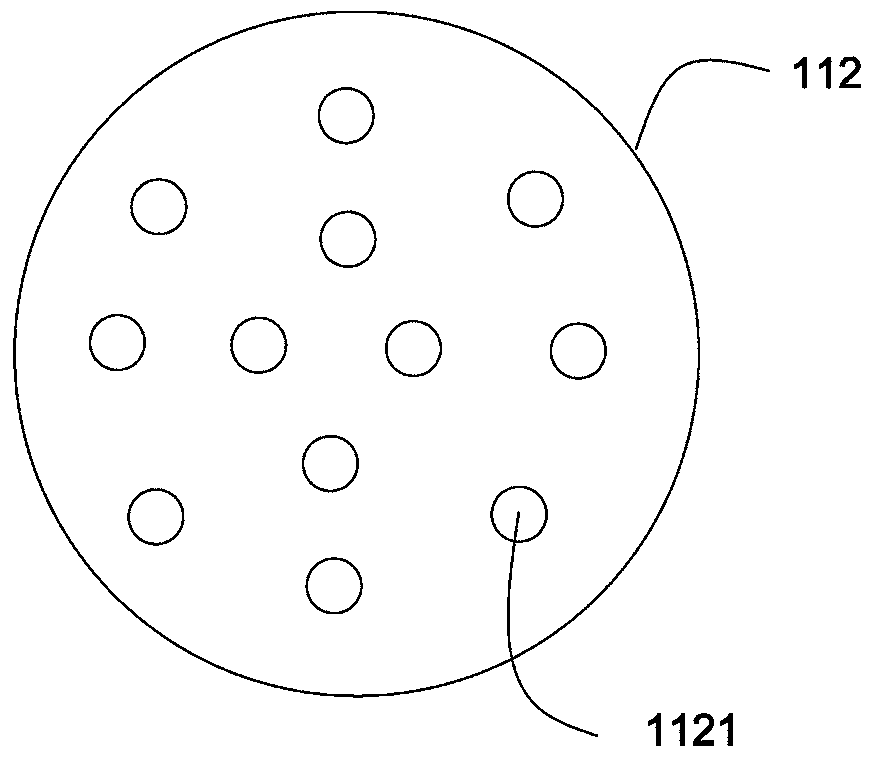

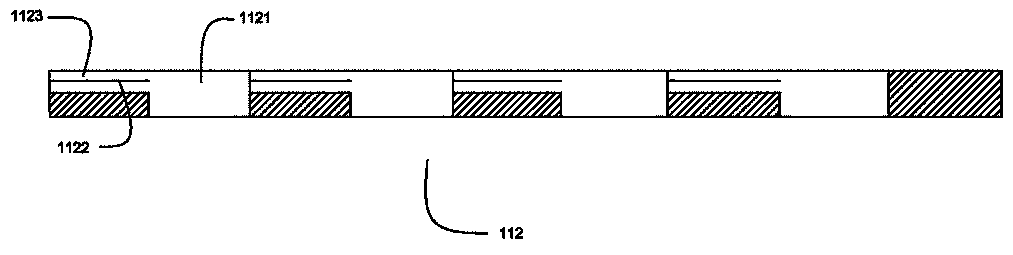

[0029] The bucket housing 1 is divided into an upper frame part 13 and a lower funnel part 14, crushing and filtering are completed in the upper frame part, and material feeding is completed by the lower funnel part. The upper end of the bucket housing 1 is provided with a material inlet 15 , and the lower end of the bucket housing 1 is provided with a discharge opening 16 . The crushing structure 11 is arranged on the upper frame portion 13, and the crushing structure 11 includes a pulverizer 111 and a support plate 112 arranged below the pulverizer 111 and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com