Seamless thin-wall stainless steel water pipe production process

A stainless steel pipe and production process technology, applied in the field of seamless thin-walled stainless steel water pipe production technology, can solve the problems of poor safety, complicated connection and installation procedures, and high cost, and achieves low internal and external surface roughness, thermal insulation and high cost. The effect of avoiding condensation and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

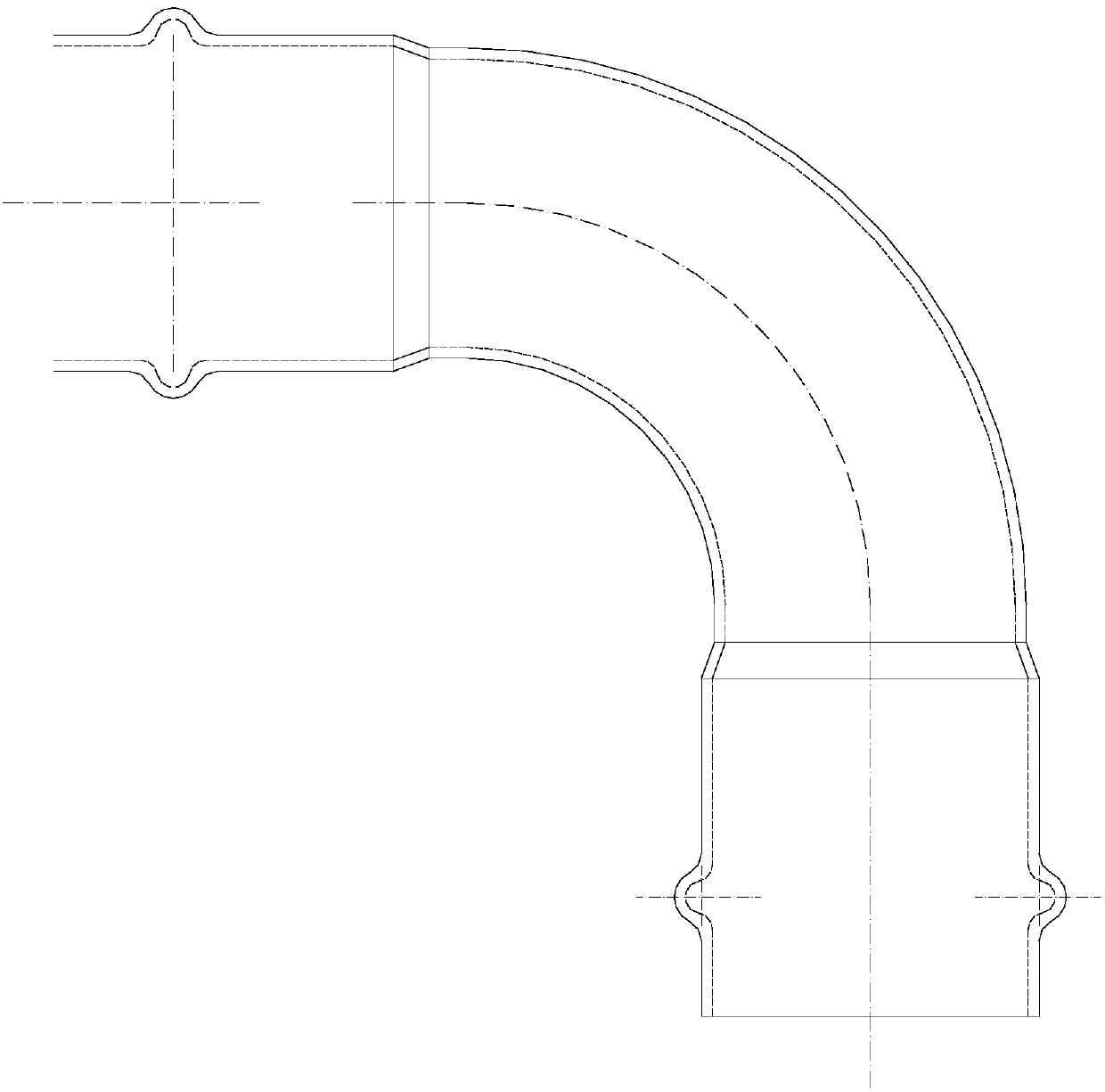

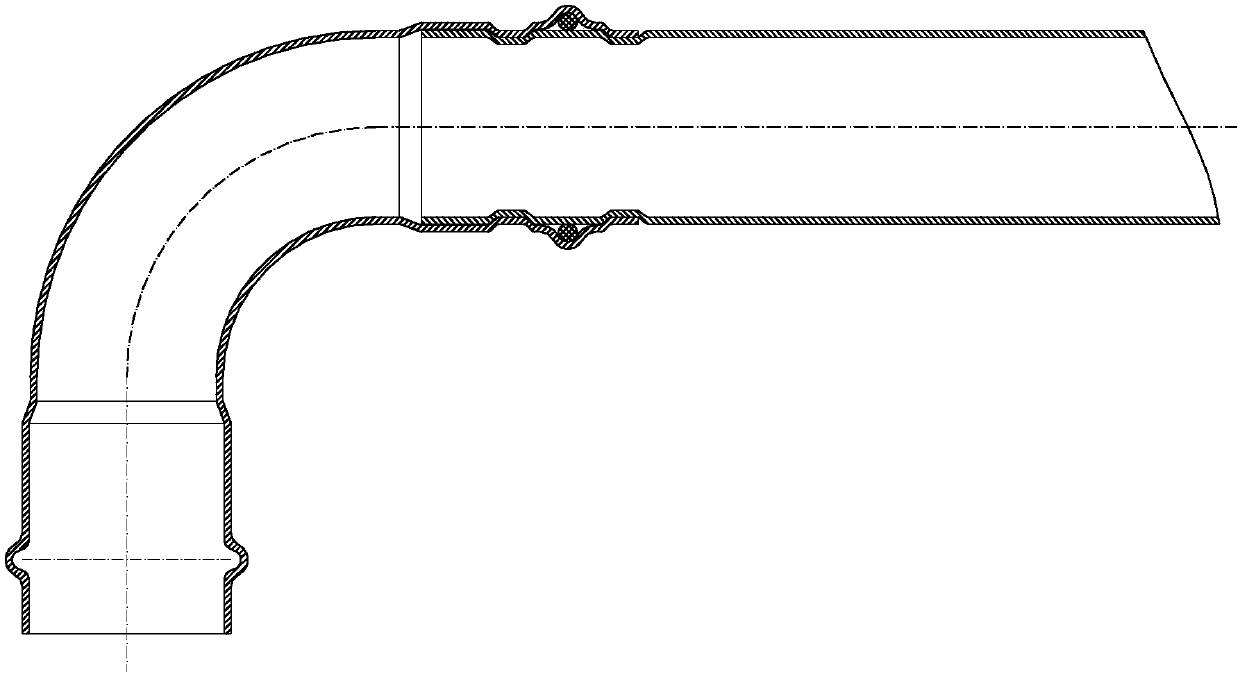

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment;

[0031] This embodiment provides a kind of seamless thin-walled stainless steel water pipe production process, comprising the following steps:

[0032] Steelmaking: S30408 stainless steel is obtained through the steelmaking process;

[0033] Hot-rolled round steel: round steel with a diameter of 65 mm produced by hot-rolling equipment;

[0034] Peeling and piercing: pass the round steel through a peeling machine and a piercing machine to obtain a tube blank with an outer diameter of 68 mm and a wall thickness of 4.8 mm;

[0035] Two-roll cold-rolled blanking: the tube billet is first blanked to an outer diameter of 38 mm and a wall thickness of 2 mm through a cold rolling mill, and then cold-drawn to a shape of 32 mm and a wall thickness of 1.5 mm;

[0036] Three-roll finish-rolled finished pipe: seamless thin-walled stainless steel pipes are pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com