Commercial vehicle electric hydraulic power steering device and use method

A technology of hydraulic power steering and electric steering, which is applied in the direction of power steering mechanism, steering mechanism, fluid steering mechanism, etc., which can solve the problems of poor steering control effect and unsuitability for electric commercial vehicles, etc., to reduce power consumption, enhance portability, Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

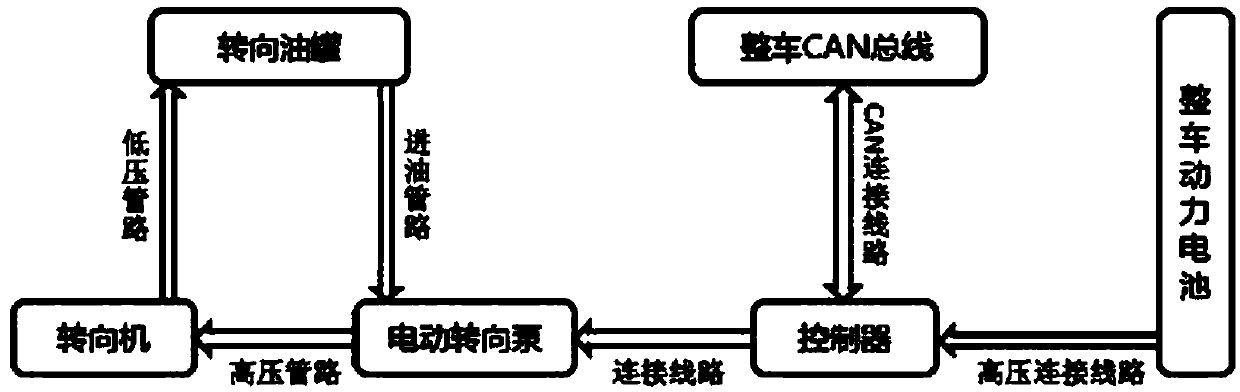

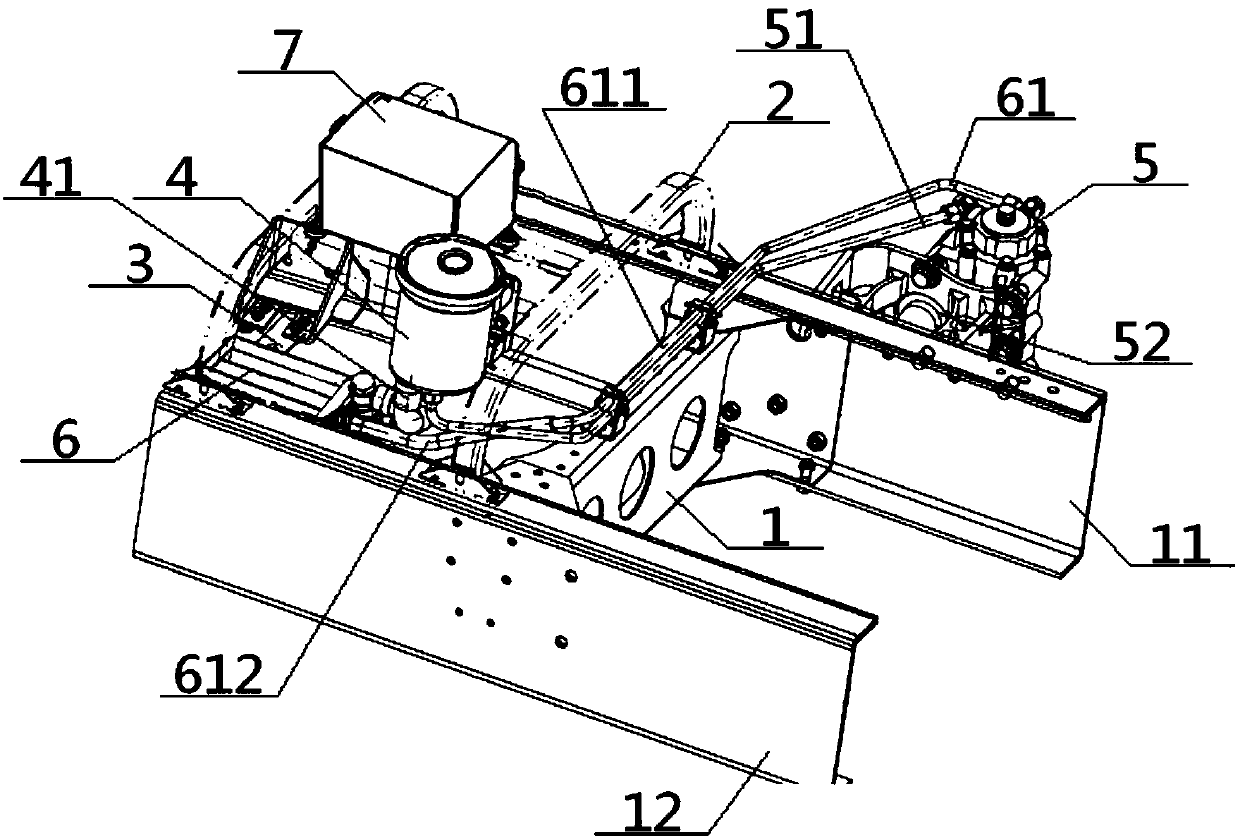

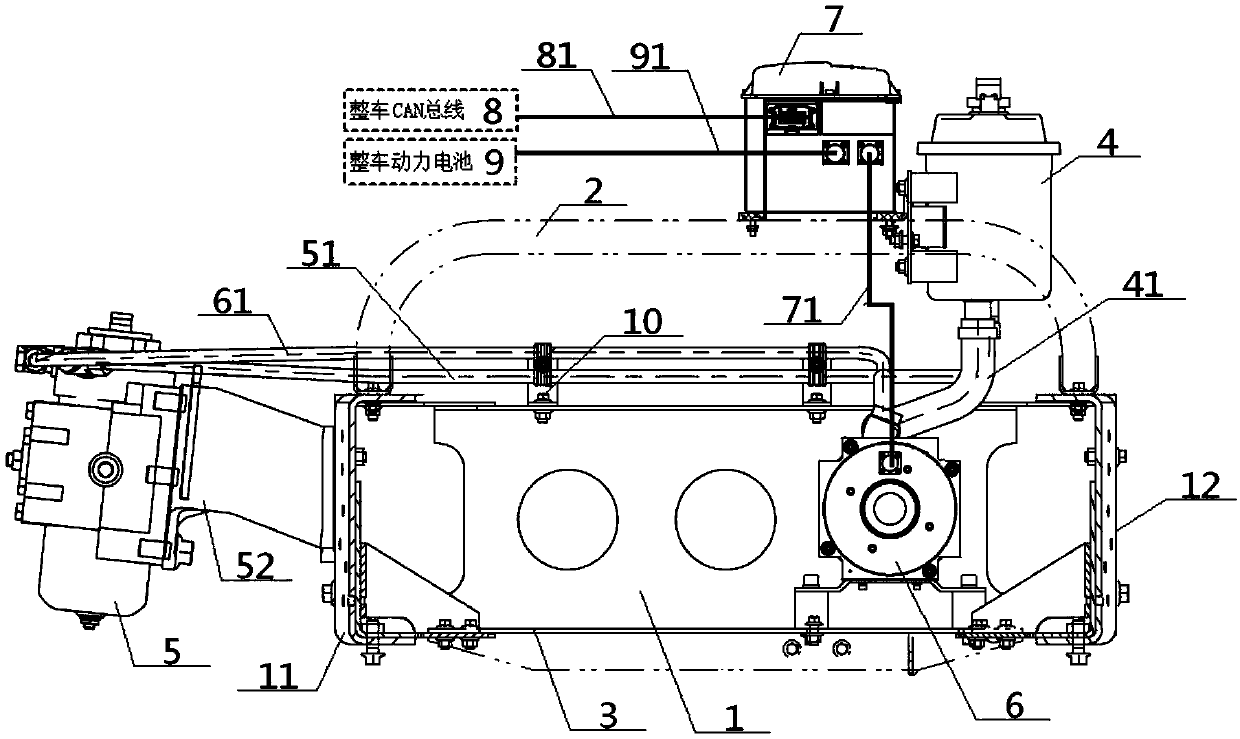

[0054] see Figure 1 to Figure 6 , an electrohydraulic power steering device for a commercial vehicle, comprising a steering oil tank 4, a steering gear 5, an electric steering pump 6 and a controller 7; The oil inlet of the electric steering pump 6 communicates with the oil inlet of the steering gear 5 through the high-pressure pipeline 61, and the oil outlet of the steering gear 5 communicates with the oil inlet of the steering oil tank 4 through the low-pressure pipeline 51 communicated, and the electric steering pump 6 is electrically connected to the controller 7 via the control circuit 71 . Preferably, the electric steering pump 6 includes a motor 62 and a mechanical pump 63, the motor 62 is connected with the mechanical pump 63 through a flexible coupling, the steering oil tank 4 communicates with the mechanical oil inlet 631 of the mechanical pump 63 through the oil inlet pipeline 41, and the mechanical pump The mechanical oil outlet 632 of 63 communicates with the st...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] The control of the controller 7 through the control circuit 71 includes any one or a combination of the following two processes:

[0060] The first process: the CAN bus 8 of the whole vehicle determines whether the controller 7 works and the voltage and frequency output by the controller 7 through the CAN bus connection line 81, so as to adjust the working time and the rotating speed of the electric steering pump 6;

[0061] The second process: the vehicle power battery 9 inputs high-voltage direct current to the controller 7 through the high-voltage connection line 91, the high-voltage direct current is converted into alternating current through the controller 7, and the controller 7 then inputs alternating current to the electric steering pump 6 through the control line 71 to drive The electric steering pump 6 works, the frequency of the alternating current determines the rotation speed of the moto...

Embodiment 3

[0063] Basic content is the same as embodiment 1, the difference is:

[0064] The input end of the controller 7 is connected with the vehicle CAN bus 8 through the CAN bus connection line 81, and the input end of the controller 7 is connected with the vehicle power battery 9 through the high voltage connection line 91. The controller 7 The output end of the control circuit 71 is electrically connected to the electric steering pump 6 . The high-voltage connection line 91 outputs direct current to the controller 7 , and the control line 71 outputs alternating current to the electric steering pump 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com