A kind of synthetic method of modified naphthalene series sulfonate water reducer

A technology of naphthalene sulfonate and synthesis method, which is applied in the field of synthesis of modified naphthalene sulfonate water reducer, can solve the problems of low economic cost and high use efficiency, achieve high concentration, reduce raw material cost, and easy good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

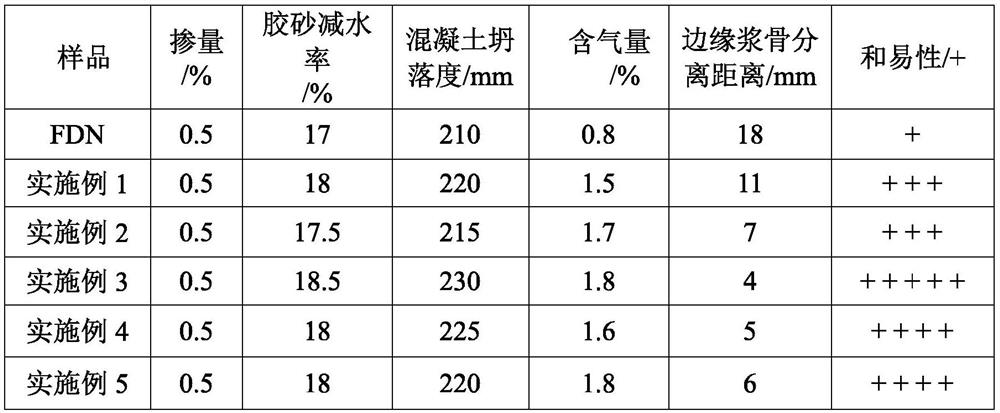

Examples

Embodiment 1

[0024] (1) Sulfonation: In parts by mass, add 100 parts of industrial naphthalene to the reactor, and when heating to 120°C, start to drop 130 parts of reclaimed acid, and complete the dropwise addition within 1 hour; when the reclaimed acid is added dropwise, The temperature in the reaction kettle was controlled at 160°C, and the temperature was continued for 3 hours;

[0025] (2) Hydrolysis: in parts by mass, after the sulfonation reaction is completed, cool down to 120°C, add 50 parts of water, and carry out the hydrolysis reaction for 30 minutes;

[0026] (3) Condensation: in parts by mass, after the hydrolysis reaction ends, cool down to 98°C, add dropwise 60 parts of formaldehyde solution with a concentration of 37wt%, and complete the dropwise addition within 2 hours; heat up to 103°C, and keep warm for 3h; Add 15 parts of hot water not lower than 60°C in 2 times to adjust the viscosity of the material, and finally dilute with 300 parts of water according to demand;

...

Embodiment 2

[0029] (1) Sulfonation: In terms of parts by mass, add 100 parts of industrial naphthalene to the reaction kettle, and when the temperature rises to 120°C, start to add 135 parts of recovered acid dropwise, and the dropwise addition is completed within 1.5 hours; when the recovered acid is added dropwise , the temperature in the reactor is controlled at 160°C, and the temperature is kept for 3 hours;

[0030] (2) Hydrolysis: in parts by mass, after the sulfonation reaction is completed, cool down to 120°C, add 50 parts of water, and carry out the hydrolysis reaction for 30 minutes;

[0031] (3) Condensation: in parts by mass, after the hydrolysis reaction ends, cool down to 98°C, add dropwise 63 parts of formaldehyde solution with a concentration of 37wt%, and complete the dropwise addition within 2 hours; heat up to 103°C, and keep warm for 3h; Add 15 parts of hot water not lower than 60°C in 2 times to adjust the viscosity of the material, and finally dilute with 300 parts o...

Embodiment 3

[0034] (1) Sulfonation: In parts by mass, add 100 parts of industrial naphthalene to the reactor, and when the temperature is raised to 120°C, start to add 1358 parts of recovered acid dropwise, and the dropwise addition is completed within 1.5 hours; when the recovered acid is added dropwise , the temperature in the reactor was controlled at 162°C, and the temperature was kept for 4 hours;

[0035] (2) Hydrolysis: in parts by mass, after the sulfonation reaction is completed, cool down to 120°C, add 55 parts of water, and carry out the hydrolysis reaction for 30 minutes;

[0036] (3) Condensation: in parts by mass, after the hydrolysis reaction ends, cool down to 98°C, add dropwise 63 parts of formaldehyde solution with a concentration of 37wt%, and complete the dropwise addition within 3 hours; heat up to 105°C, and keep warm for 5h; Add 18 parts of hot water not lower than 60°C in 2 times to adjust the viscosity of the material, and finally dilute with 300 parts of water as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com