Lubricating oil and application thereof

A technology of lubricating oil and base oil, applied in the field of lubricating oil, can solve the problem of strict requirements on anti-wear performance, and achieve the effect of strong anti-friction performance, fuel saving and good protection.

Inactive Publication Date: 2018-05-15

金雪驰科技(马鞍山)有限公司 +3

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Now consumers have higher and higher requirements for car comfort. Wear reduction, low noise, energy saving, and long oil change intervals have become hot spots, which have also aroused the exploration of lubricating oil manufacturers. Meets increasingly demanding requirements, especially in the field of diesel engines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

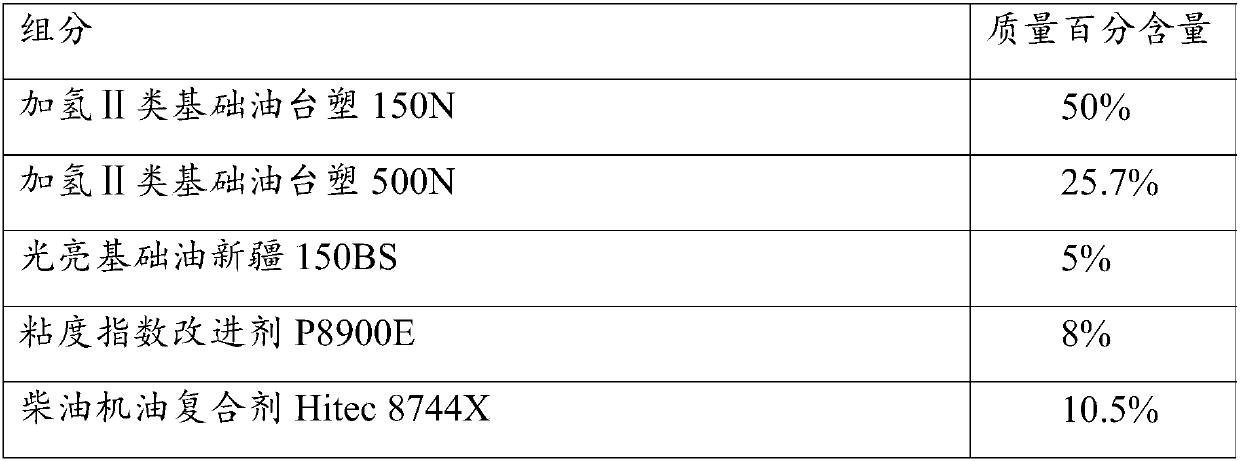

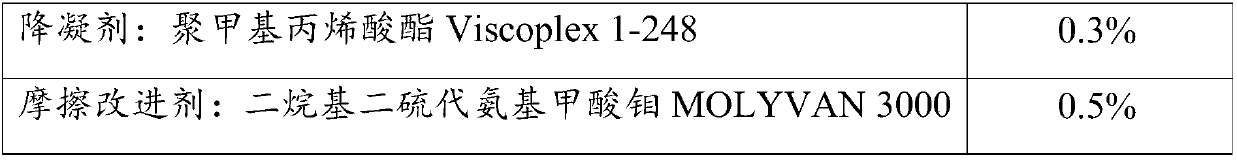

Embodiment 1

[0031] A kind of lubricating oil, formula such as table 1.

[0032] Table 1

[0033] components

Embodiment 2

[0035] A kind of lubricating oil in the present embodiment is made up of the component in table 2.

[0036] Table 2

[0037]

[0038]

Embodiment 3

[0040] A lubricating oil in this embodiment is composed of the following components in Table 3.

[0041] table 3

[0042] components

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides lubricating oil and application thereof. The lubricating oil is prepared from the following components by weight percent: 70-90% of base oil, 6-15% of a diesel engine oil compound agent, 3-15% of a viscosity index improver, 0.1-0.5% of a pour point depressant and 0.1-1% of friction improver, wherein the base oil is prepared by mixing hydrogenated base oil II and brighteningbase oil. The lubricating oil is prepared from the base oil and the additives; a good synergistic effect is achieved due to the combination of the compound type base oil and the improvers, so that theanti-friction, anti-wear and energy-saving effects are enabled to be more obvious. Under the actual working conditions, molybdenum dialkyl dithiophosphate or molybdenum dialkyl dithiocarbamate release active element sulfur or phosphorus in a friction process under high temperature and high pressure and chemically react with the metals on the friction surface, so that complex compounds such as phosphides and sulfides are generated and deposited on the friction surface; therefore, the lubricating oil has the effects of wear resistance, noise reduction and energy conservation on engines, and theengines, cylinders and other equipment are better protected by means of the lubricating oil.

Description

technical field [0001] The invention relates to the field of engine oil, in particular to a lubricating oil and its application. Background technique [0002] Friction produces force, which has different meanings in different environments. For the engine system, the friction from the mechanical parts will cause the wear of the mechanical parts and the effort of the movement. When we fill the equipment with lubricating oil (commonly known as "oil"), the lubricating oil is forced to circulate or splash through the oil pump. Among the friction parts of the engine, an oil film is formed on the surface of the friction parts, so that the dry friction between metals on the friction surface becomes a liquid friction between lubricating oils. Now consumers have higher and higher requirements for car comfort. Wear reduction, low noise, energy saving, and long oil change intervals have become hot spots, which have also aroused the exploration of lubricating oil manufacturers. Meets i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10N40/25C10N30/06C10N30/04C10N30/12

CPCC10M169/048C10M2203/1025C10M2209/08C10M2219/068C10M2223/045C10N2010/12C10N2020/02C10N2030/04C10N2030/06C10N2030/12C10N2030/76C10N2040/252

Inventor 徐芹龙张艳王锐峰王蒙蒙付传瑞马跃峰

Owner 金雪驰科技(马鞍山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com