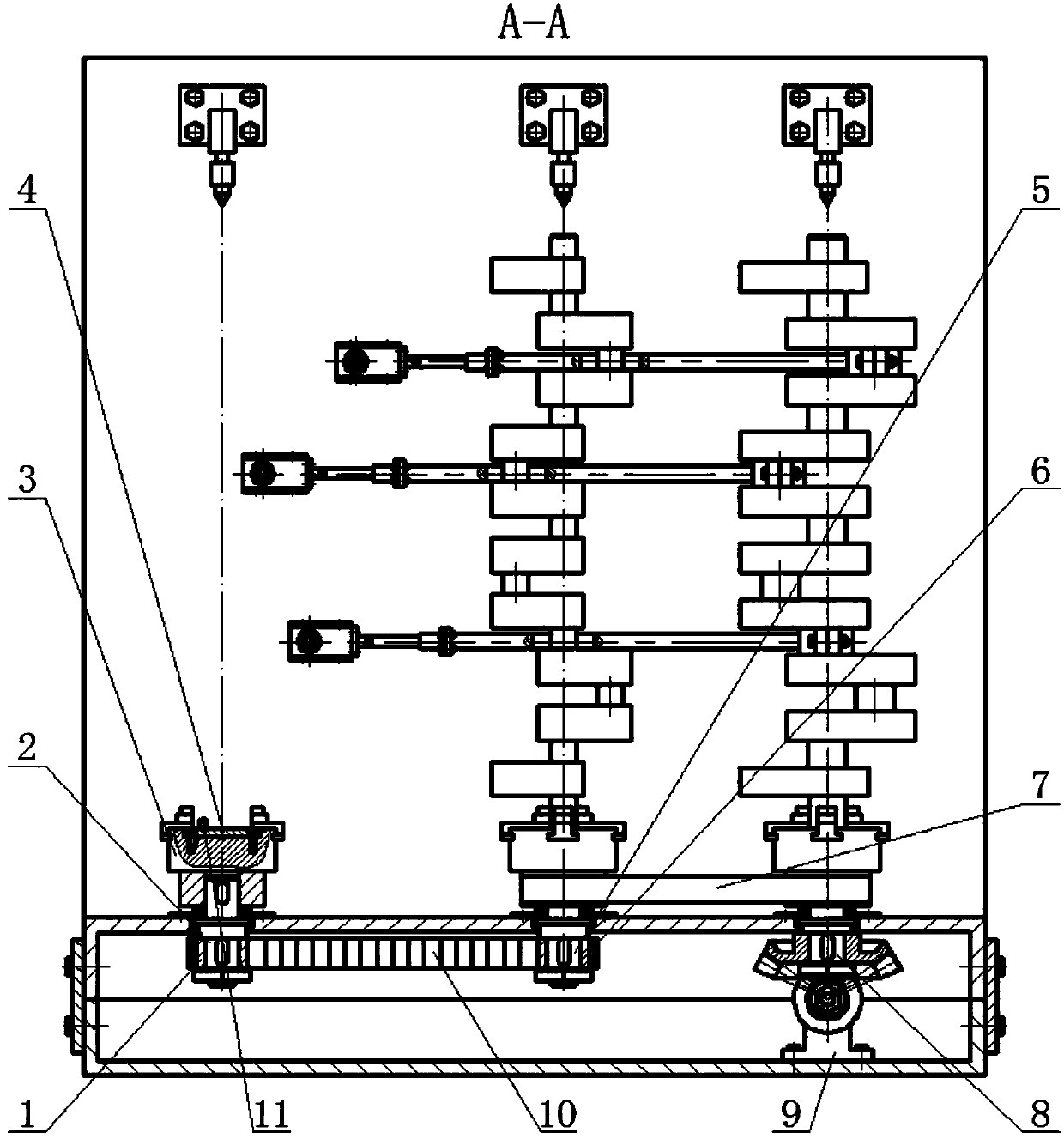

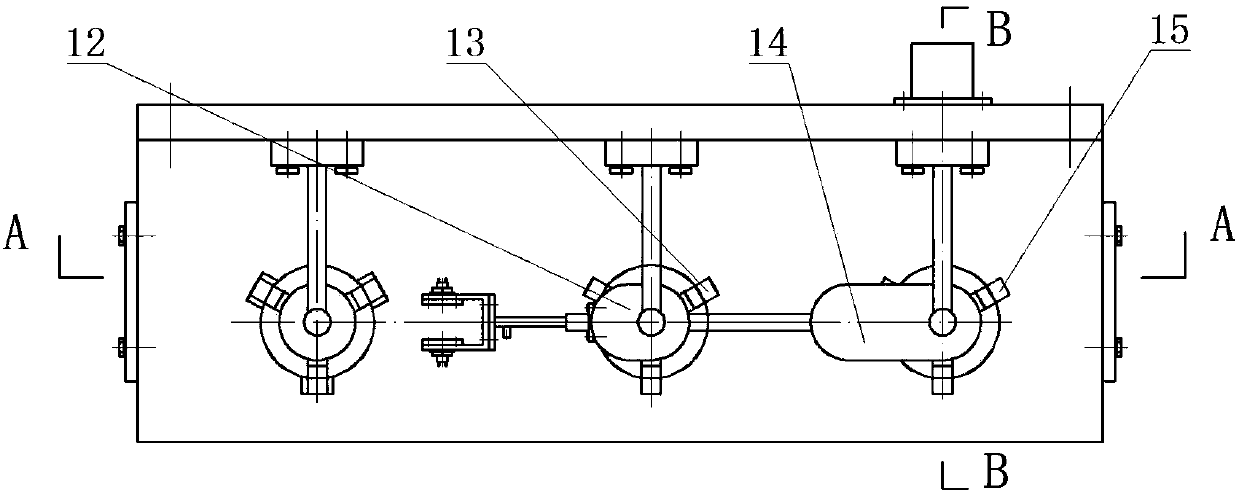

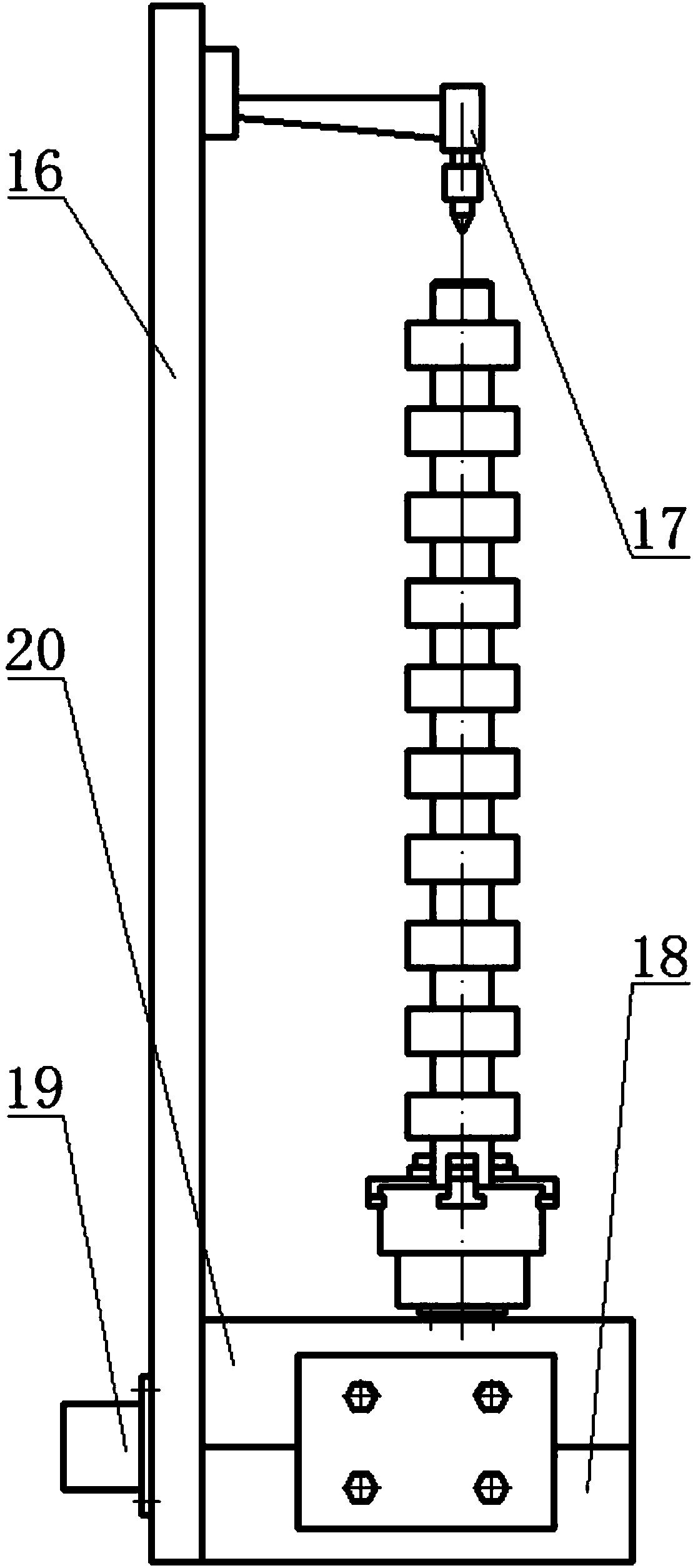

Synchronous heat treatment device for on-line producing crankshafts

A heat treatment device and crankshaft technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of not being able to use a crankshaft production line, increase crankshaft deformation, and high heat treatment costs, and achieve the effects of small deformation, uniform heating and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The workflow of a kind of on-line crankshaft synchronous heat treatment device provided by the present invention is as follows:

[0034] During the heat treatment of the crankshaft, the crankshaft is positioned and clamped by the positioning and clamping mechanism, the parallelogram mechanism and the crankshaft are driven by the synchronous transmission mechanism to rotate synchronously, and the parallelogram mechanism drives the induction heating mechanism to move in translation in the horizontal plane to ensure that the induction heater is in contact with the crankshaft shaft. The relative position of the neck remains unchanged, and it does not contact the crankshaft journal to prevent scratching the crankshaft journal. The crankshaft is heated and heat-insulated by the induction heating mechanism. The specific process includes:

[0035] The positioning and clamping mechanism realizes the positioning and clamping of the crankshaft: the crankshaft is mainly positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com