Polyester-nylon composite yarn and preparation method thereof

A polyester-nylon composite yarn and monofilament technology, applied in spinneret assembly, filament/line forming, single-component polyester rayon, etc., can solve the problems of poor moisture absorption performance, dimensional stability, single color, etc. , to achieve smooth and stable spinning, consistent extrusion speed, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

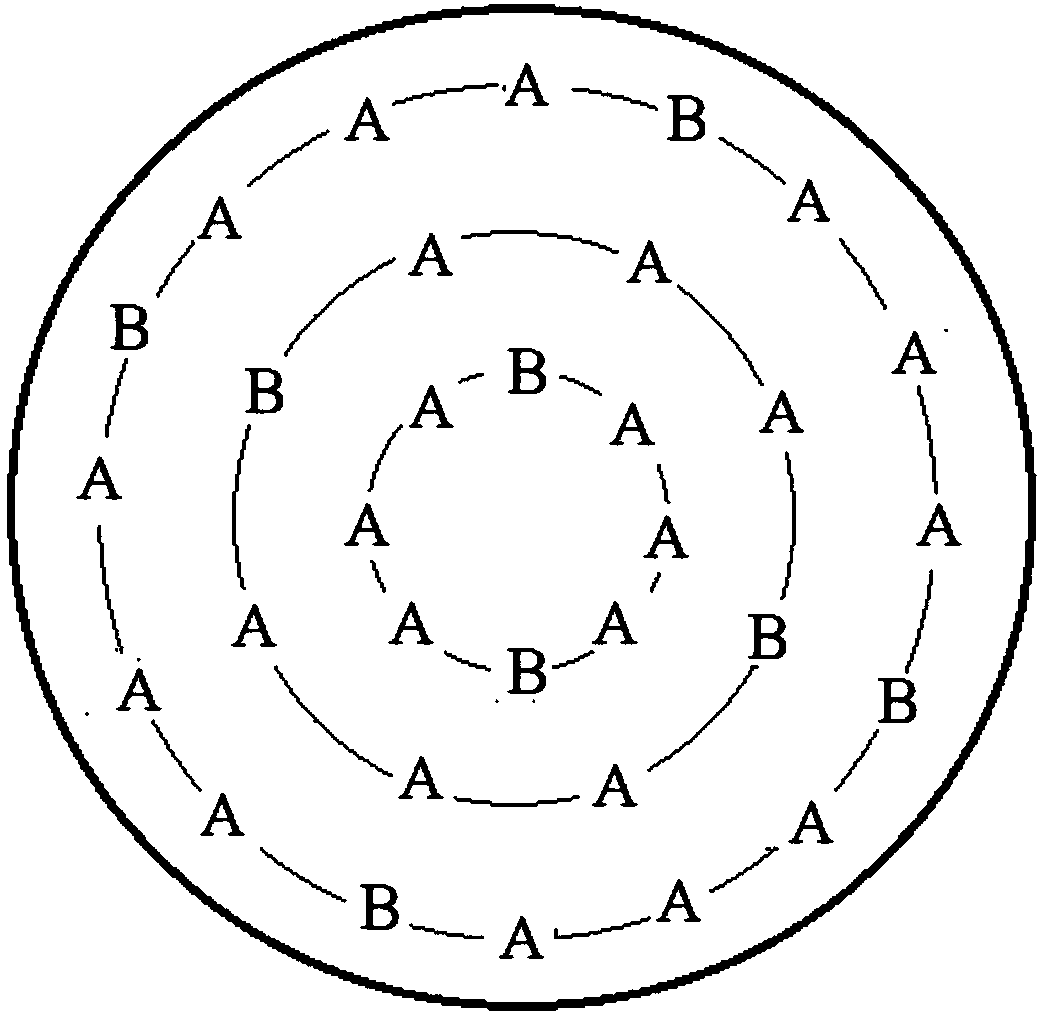

[0050] A preparation method of polyester nylon composite yarn, PET melt and PA melt are measured, compound spinneret extrusion, cooling, oiling, stretching, heat setting and winding to obtain polyester nylon composite yarn, wherein the composite There are two different spinneret holes A and B on the spinneret plate. The ratio of the micropore length of spinneret A to spinneret B is equal to the ratio of the equivalent diameter of spinneret A to spinneret B. The product of the coefficient K and the ratio of the consistency coefficient of the material flowing through the spinneret B to the material flowing through the spinneret A, the equivalent diameter is the ratio of the cross-sectional area of the spinneret to the circumference of the cross-section, and the coefficient of K The value is 1.01, and composite spinneret extrusion means that PET melt is extruded from spinneret A, and PA melt is extruded from spinneret B, wherein the micropore length of spinneret A is 1.30mm, and...

Embodiment 2

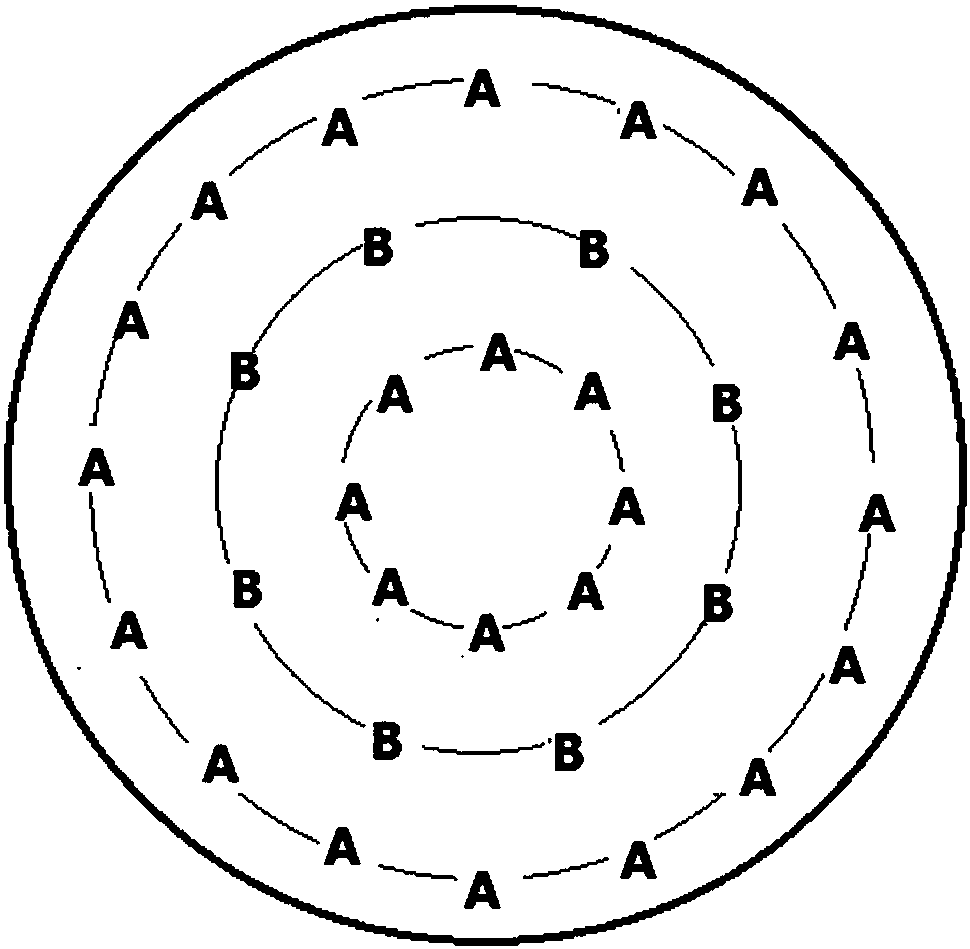

[0063] A preparation method of polyester nylon composite yarn, PET melt and PA melt are measured, compound spinneret extrusion, cooling, oiling, stretching, heat setting and winding to obtain polyester nylon composite yarn, wherein the composite There are two different spinneret holes A and B on the spinneret plate. The ratio of the micropore length of spinneret A to spinneret B is equal to the ratio of the equivalent diameter of spinneret A to spinneret B. The product of the coefficient K and the ratio of the consistency coefficient of the material flowing through the spinneret B to the material flowing through the spinneret A, the equivalent diameter is the ratio of the cross-sectional area of the spinneret to the circumference of the cross-section, and the coefficient of K The value is 0.97, and composite spinneret extrusion means that PET melt is extruded from spinneret B, and PA melt is extruded from spinneret A, wherein the micropore length of spinneret B is 0.30mm, and...

Embodiment 3

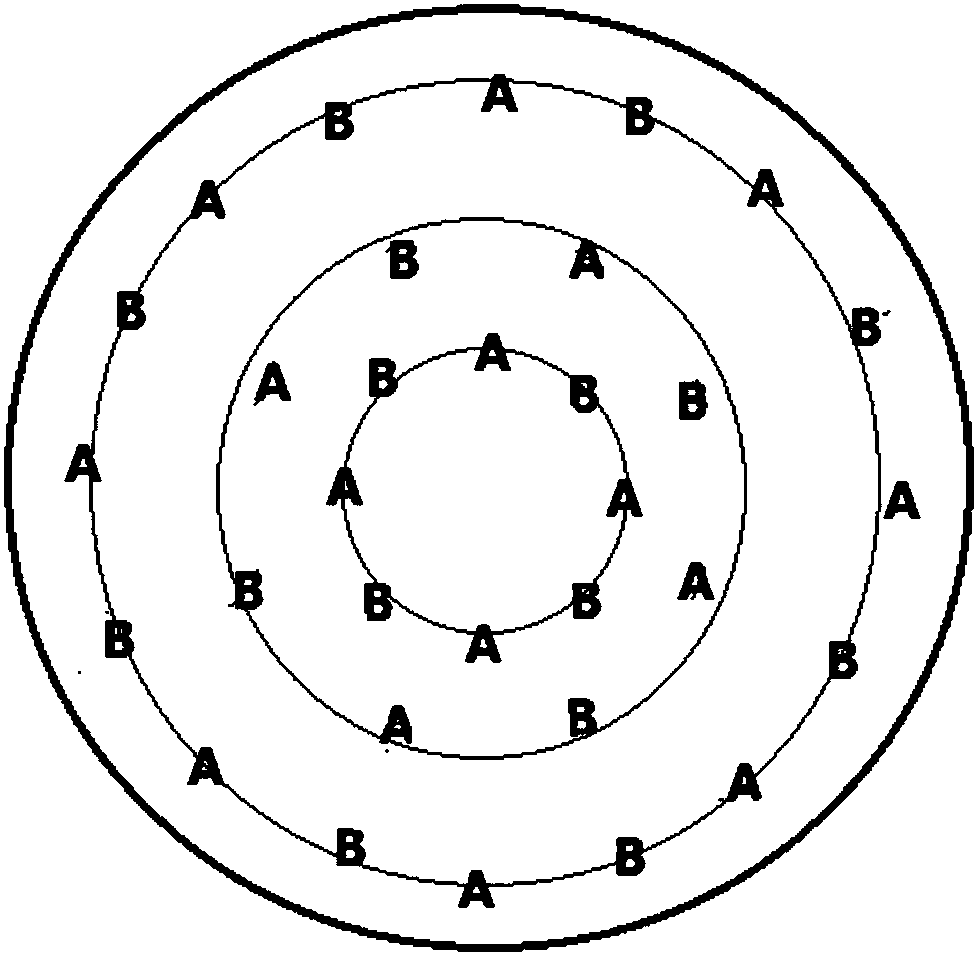

[0076] A preparation method of polyester nylon composite yarn, PET melt and PA melt are measured, compound spinneret extrusion, cooling, oiling, stretching, heat setting and winding to obtain polyester nylon composite yarn, wherein the composite There are two different spinneret holes A and B on the spinneret plate. The ratio of the micropore length of spinneret A to spinneret B is equal to the ratio of the equivalent diameter of spinneret A to spinneret B. The product of the coefficient K and the ratio of the consistency coefficient of the material flowing through the spinneret B to the material flowing through the spinneret A, the equivalent diameter is the ratio of the cross-sectional area of the spinneret to the circumference of the cross-section, and the coefficient of K The value is 1.03, and composite spinneret extrusion means that PET melt is extruded from spinneret A, and PA melt is extruded from spinneret B, wherein the micropore length of spinneret A is 1.49 mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com