Miniature thermo-sensitive flexible probe

A sensitive, flexible and miniature technology, applied in the field of temperature control sensing, it can solve the problems of insufficient insulation, limited thermal response speed, and high cost, and achieve the effect of improving thermal response sensitivity, ensuring electrical insulation performance, and maintaining small differences in stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

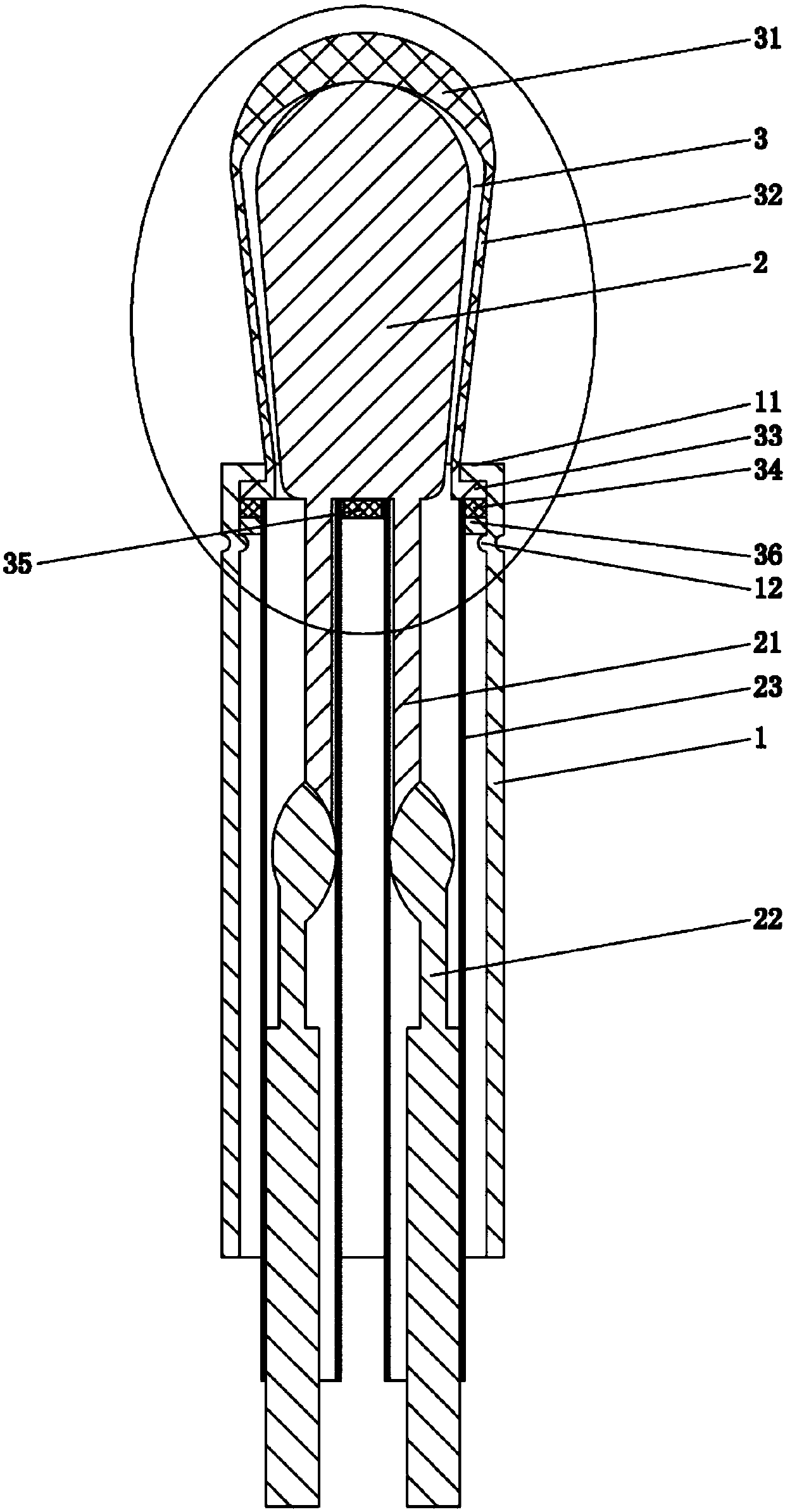

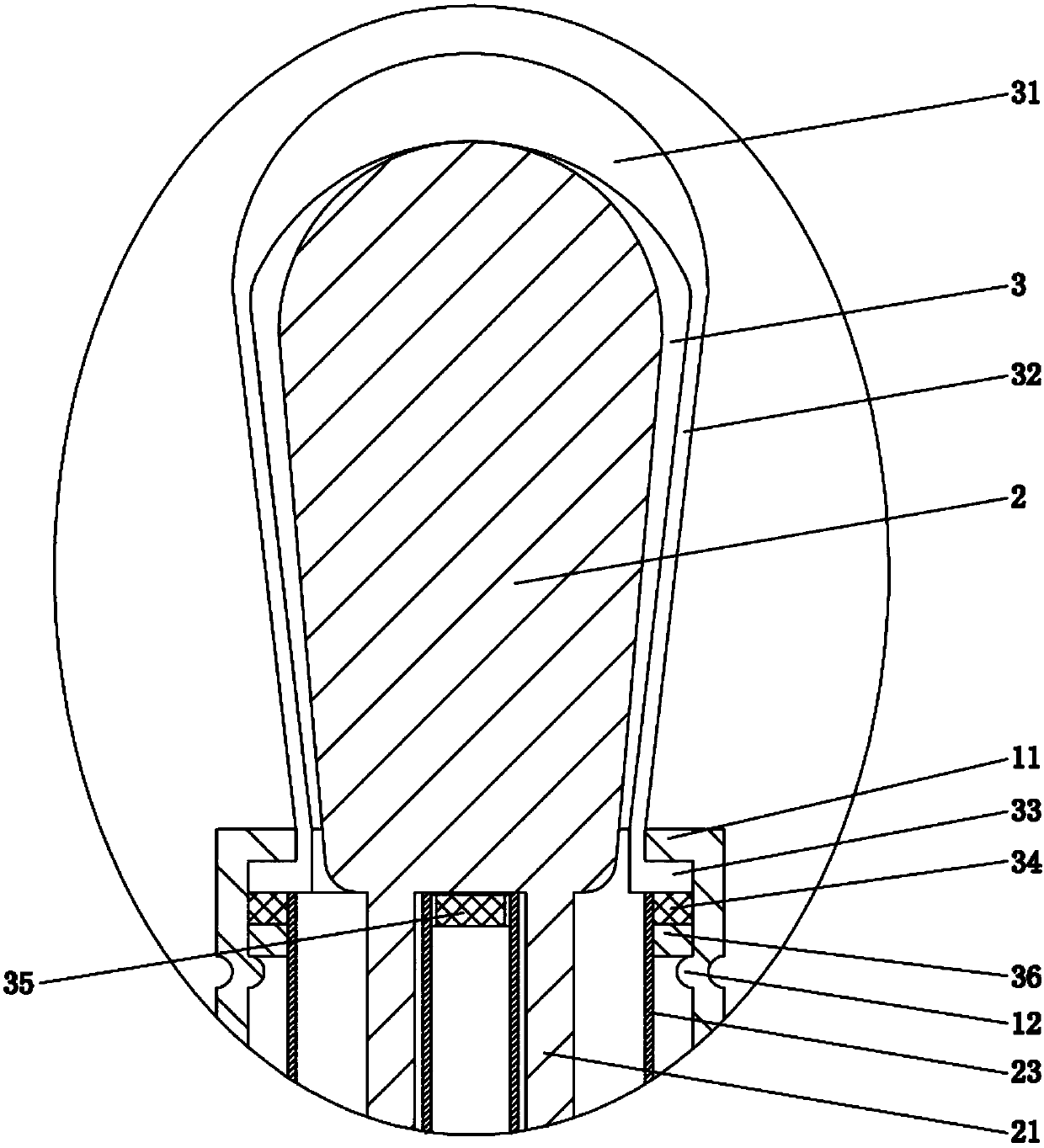

[0017] Such as figure 1 As shown, a miniature thermosensitive flexible probe described in the present invention includes a metal probe 1, a thermistor 2 and a silicone head 3, and the silicone head 3 includes an upper hemispherical part 31, a middle sleeve part 32 and a lower part The ring edge part 33, the upper port of the metal probe 1 is provided with a beam mouth ring 11, the lower end of the sleeve part 32 is set in the beam mouth ring 11 and the ring edge part 33 is attached to the inner surface of the beam mouth ring 11 The thermistor 2 is installed in the silica gel head 3, and the upper end surface of the thermistor 2 is set in conflict with the inner wall of the hemispherical part 31, and the wall thickness of the hemispherical part 31 gradually increases from the surrounding to the center of the top, and the metal probe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com