Preparation method of high-conductivity graphene-eosin Y composite aerosol photocatalyst

A composite airgel, high conductivity technology, applied in the field of materials, can solve the problem of reducing the conductivity of graphene, destroying the two-dimensional π-conjugated electronic structure of graphene, affecting the photocatalytic performance of graphene-based composite photocatalytic materials, etc. problems, to achieve the effect of easy recycling, wide application prospects, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

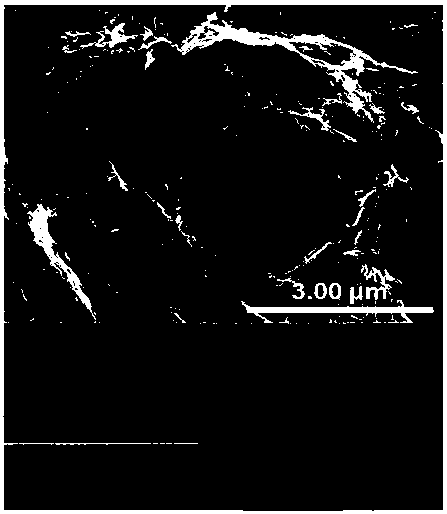

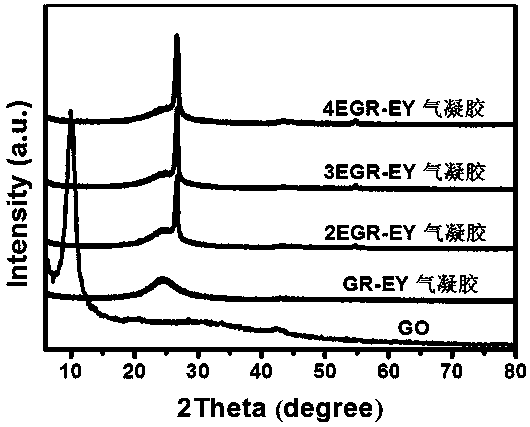

[0026] Add 2 mg of Elicarb graphene (EGR) to 10 mL of graphene oxide dispersion (concentration: 3 mg / mL), and then add 2 mg of Eosin Y (EY), and ultrasonically mix and stir evenly, then 180 °C Hydrothermal for 12 h, then cooling, washing, and vacuum freeze-drying to obtain a highly conductive graphene-eosin Y composite airgel (2EGR-EY airgel) photocatalyst.

Embodiment 2

[0028] Add 3 mg of Elicarb graphene (EGR) to 10 mL of graphene oxide dispersion (concentration: 3 mg / mL), and then add 2 mg of Eosin Y (EY), and ultrasonically mix and stir evenly, then 180 °C Hydrothermal for 12 h, then cooling, washing, and vacuum freeze-drying to obtain a highly conductive graphene-eosin Y composite airgel (3EGR-EY airgel) photocatalyst.

Embodiment 3

[0030] Add 4 mg of Elicarb graphene (EGR) to 10 mL of graphene oxide dispersion (concentration: 3 mg / mL), and then add 2 mg of Eosin Y (EY), and ultrasonically mix and stir evenly, then 180 °C Hydrothermal for 12 h, then cooling, washing, and vacuum freeze-drying to obtain a highly conductive graphene-eosin Y composite airgel (4EGR-EY airgel) photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com