Semi-automatic pounding machine for condiments

A condiment and semi-automatic technology, which is applied in the field of semi-automatic pounding machines, can solve the problems of reducing the degree of production automation, not being able to meet the needs of consumers, and reducing production efficiency, and achieve the effects of simple structure, low human participation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

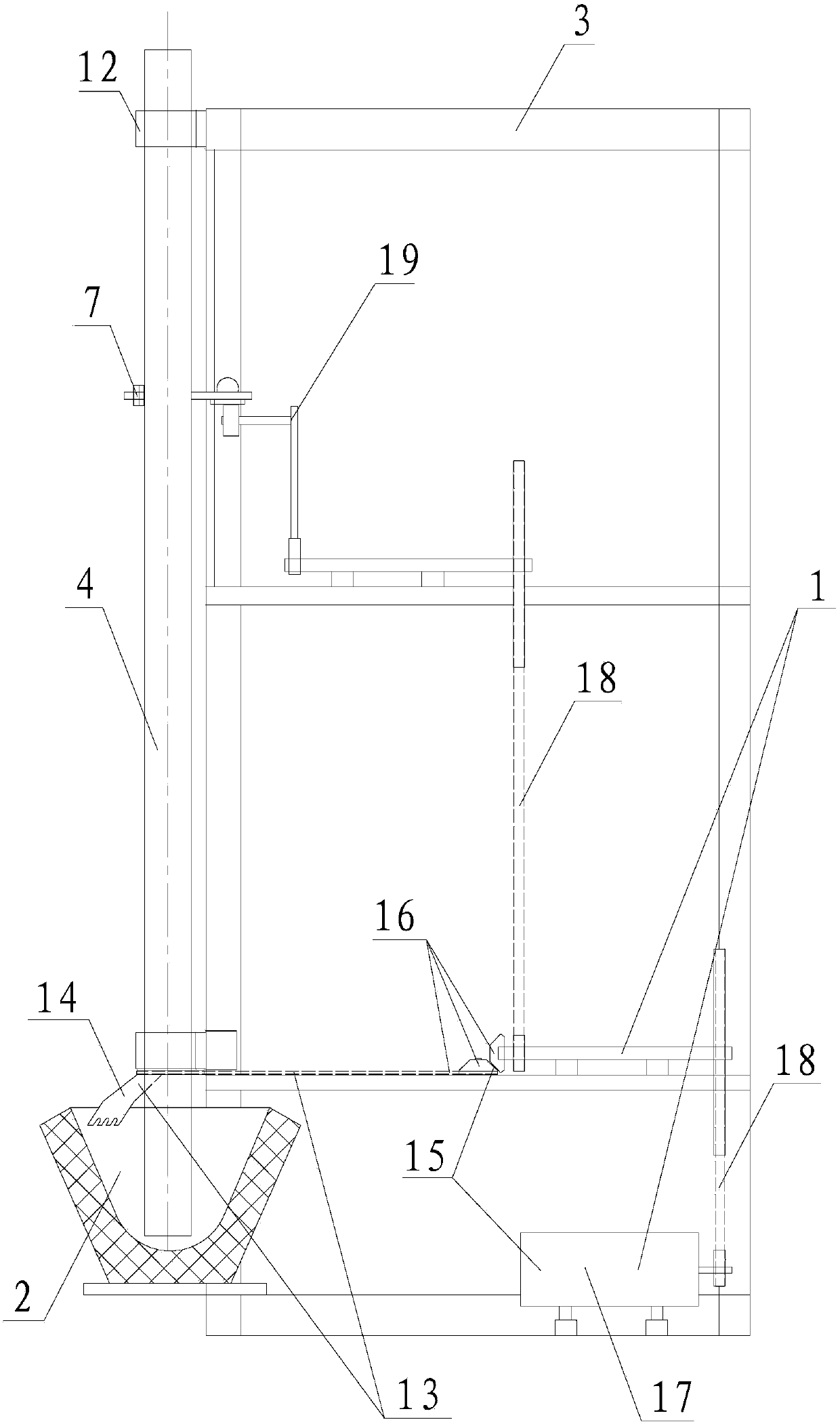

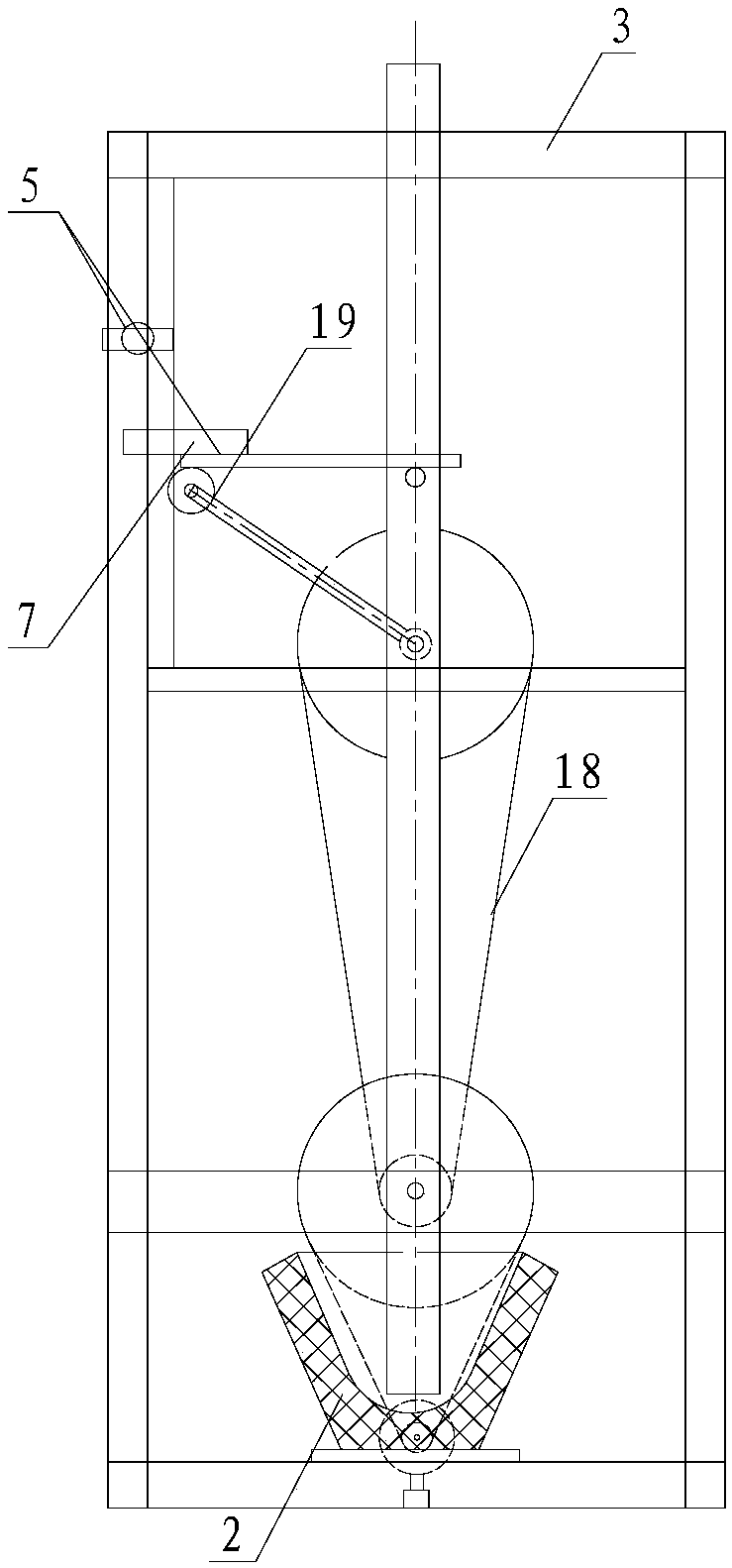

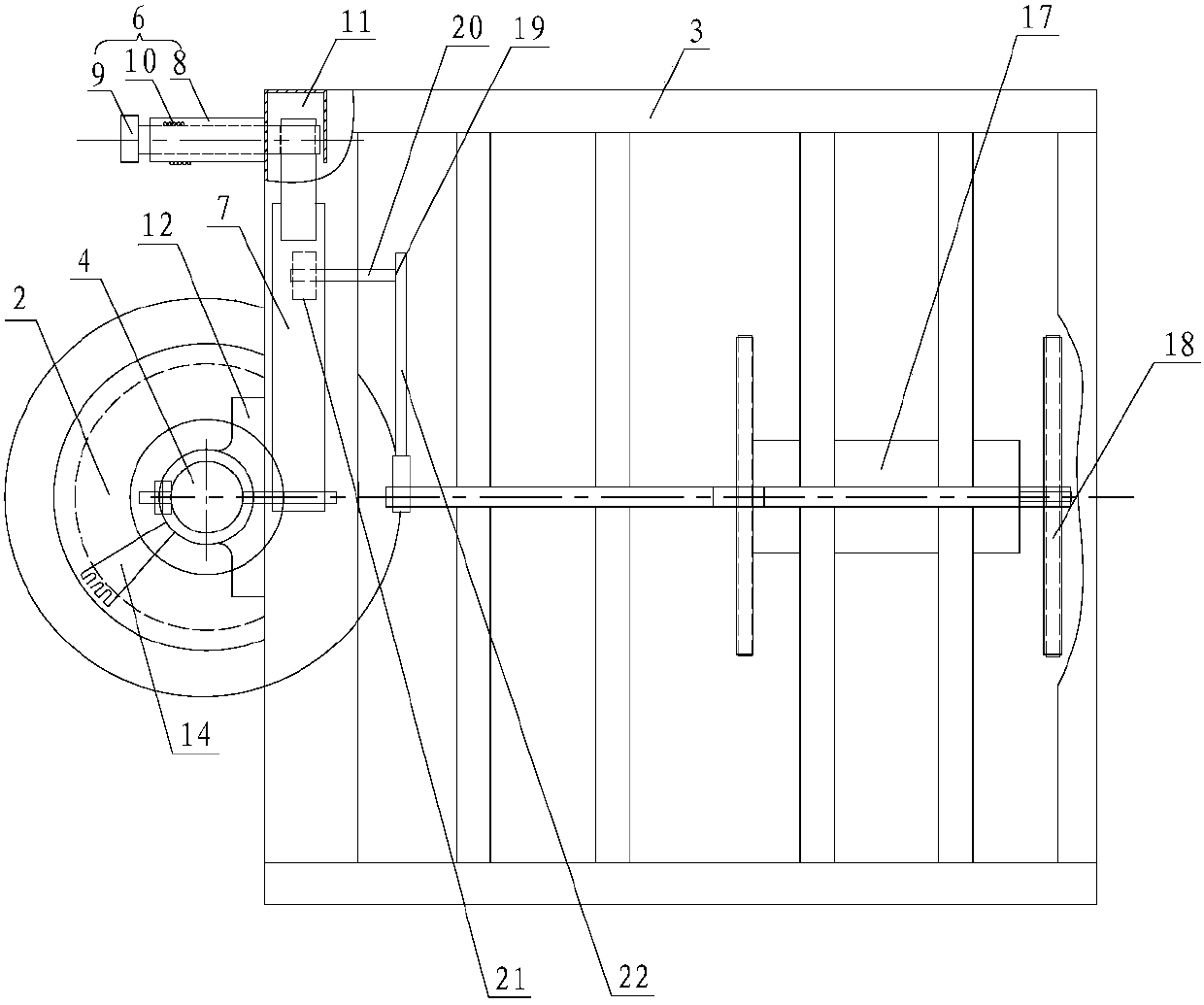

[0019] Such as figure 1 , figure 2 as well as image 3 Shown is a semi-automatic pounding machine for condiments that is easy to operate and less involved in the production process provided by the invention. The semi-automatic pounding machine includes a driving system 1, a pounding tank 2 and a vertically mounted pounding rod 4 on the frame 3, and the described pounding rod 4 is driven by the driving system 1 through its The lower part of the pounding end and the pounding tank 2 cooperate to smash the condiments located in the pounding tank 2, and the semi-automatic pounding machine also includes a locking mechanism 5 for the pounding rod, which can be moved in and out of the pounding tank 2. During the seasoning process, the pounding stick 4 is locked on the frame 3 away from the pounding tank 2 through the pounding stick locking mechanism 5 . In the present application, a set of tampering rod locking mechanism is provided, and during the process of entering and exiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com