Flotation cell anti-corrosion method in sulfur flotation technology

A flotation tank and sulfur flotation technology, applied in flotation, solid separation, etc., can solve problems such as increasing the burden on enterprises, affecting the normal operation of enterprises, and interrupting production, and achieve simple and convenient construction difficulty, good anti-corrosion effect, and reduced The effect of maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

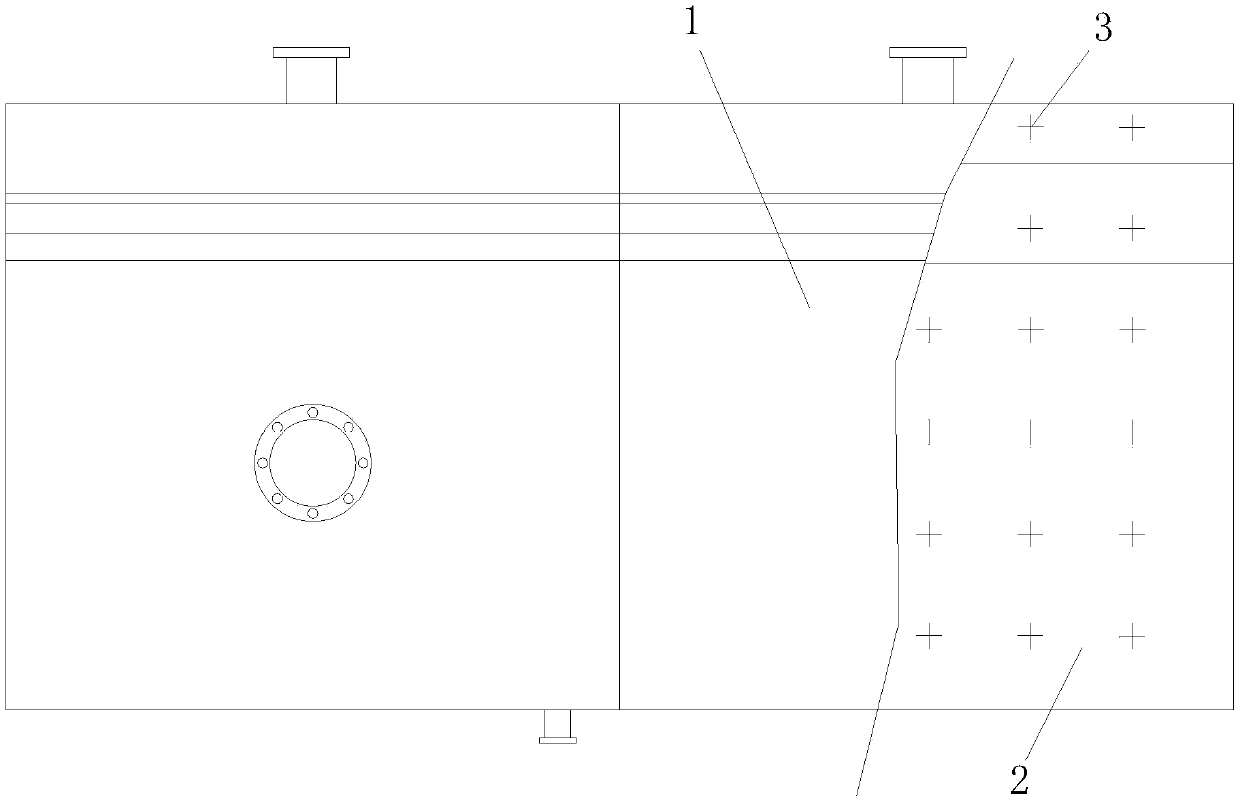

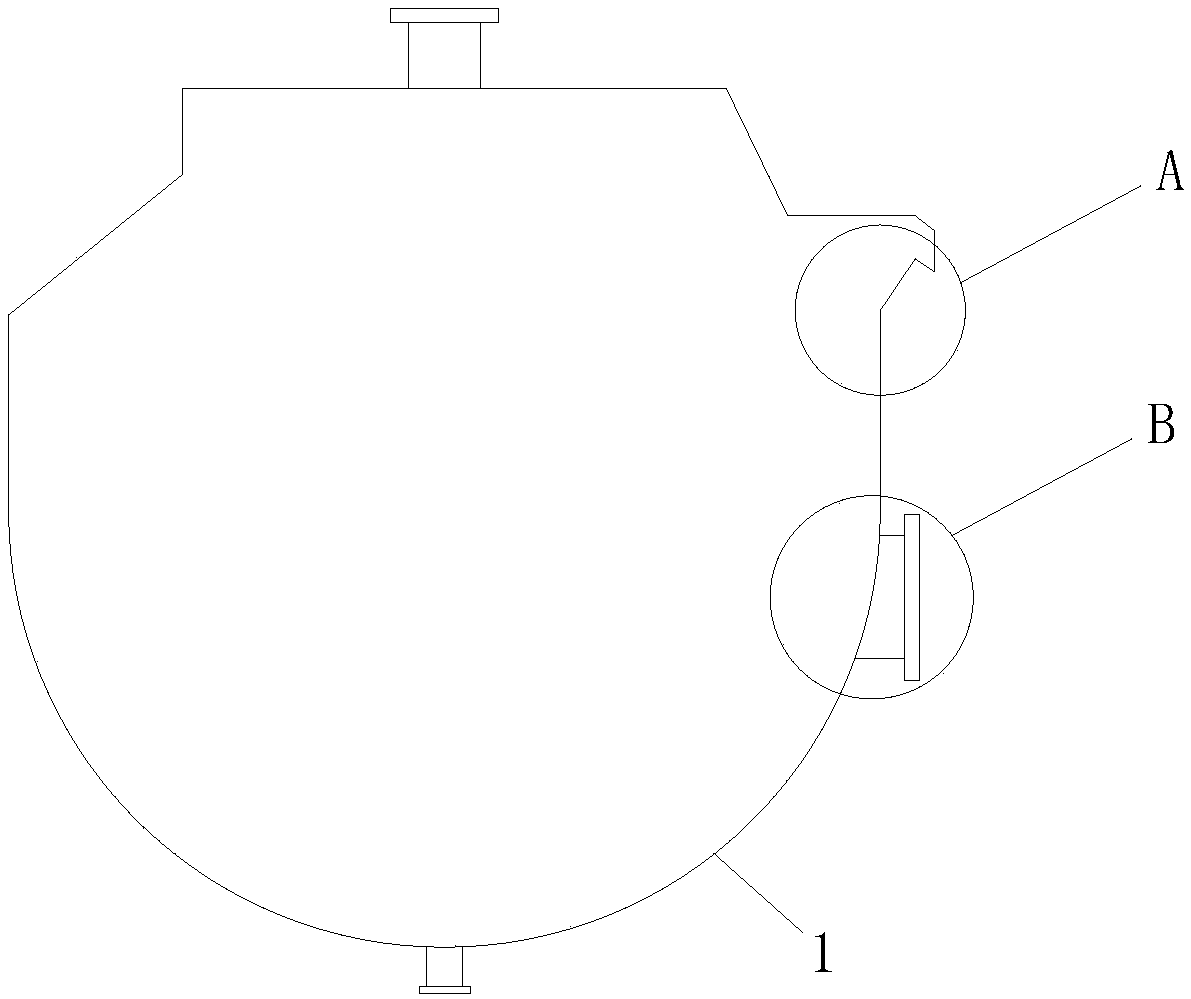

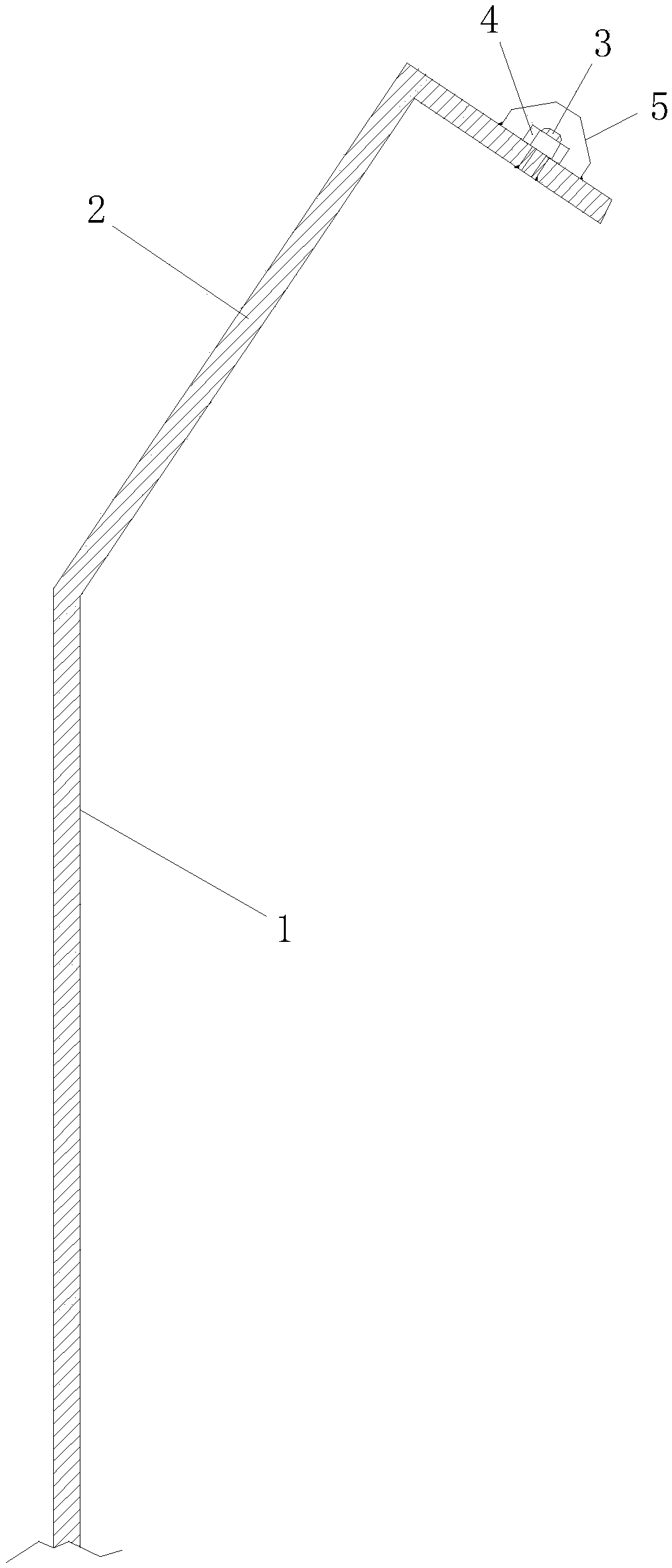

[0020] In this example, refer to figure 1 , figure 2 , image 3 and Figure 4 , the anti-corrosion method of the flotation cell in the sulfur flotation process, the first step, the stirring equipment and the support in the stainless steel cell 1 are removed, and the inside of the stainless steel cell 1 is polished smooth, and the attached pipeline is connected The second step is to pre-drill the PP plate 2, weld the PP flange, and polish it smooth at the same time; the third step is to weld the stainless steel bolts 3 evenly in the stainless steel tank body 1, so that the stainless steel bolts 3 are separated from the stainless steel tank body 1. The inner surface of the inner surface protrudes inward; the fourth step is to fix the drilled PP board 2 on the stainless steel bolt 3 of the stainless steel tank 1 and press it with the nut 4 to eliminate the gap between the PP board 2 and the inner wall of the stainless steel tank 1. The fifth step is to cover the extended end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com