Vinasse waste liquid centrifuge

A centrifuge and waste liquid technology, applied in the field of centrifuges, can solve problems such as drum wear, spiral blade wear, and spiral barrel failure, and achieve the effects of reducing erosion and wear, increasing service life, and reducing overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

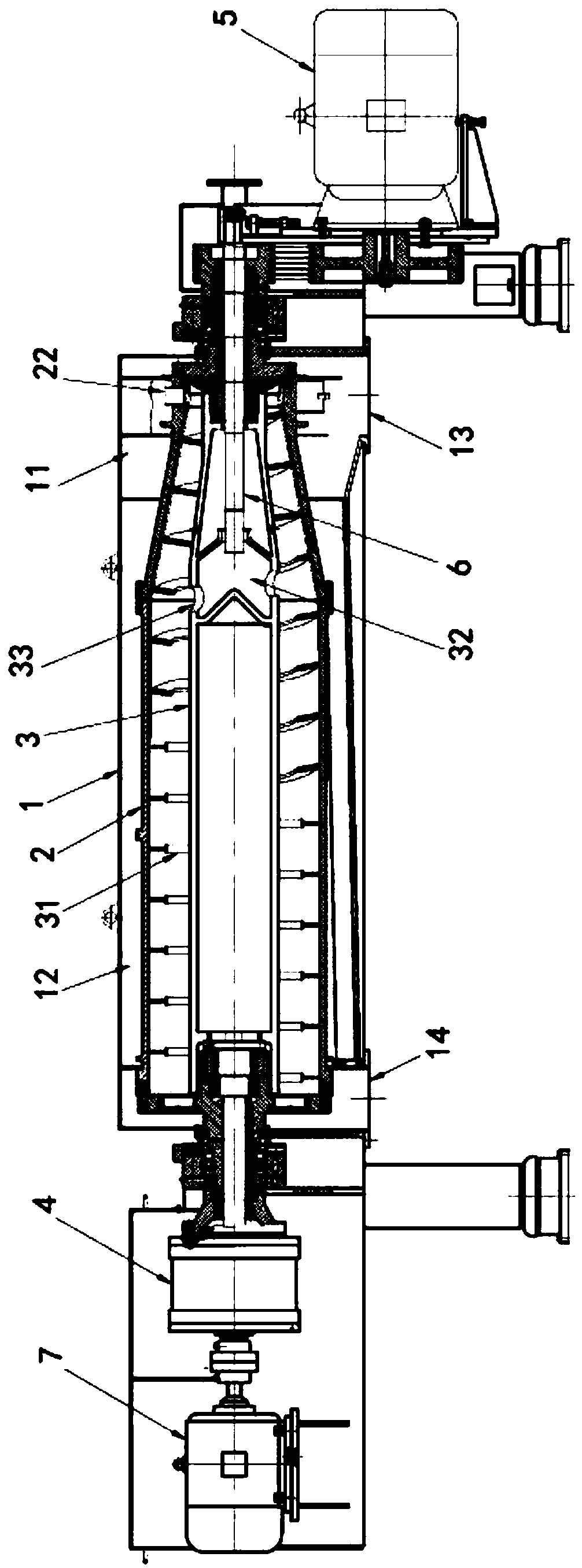

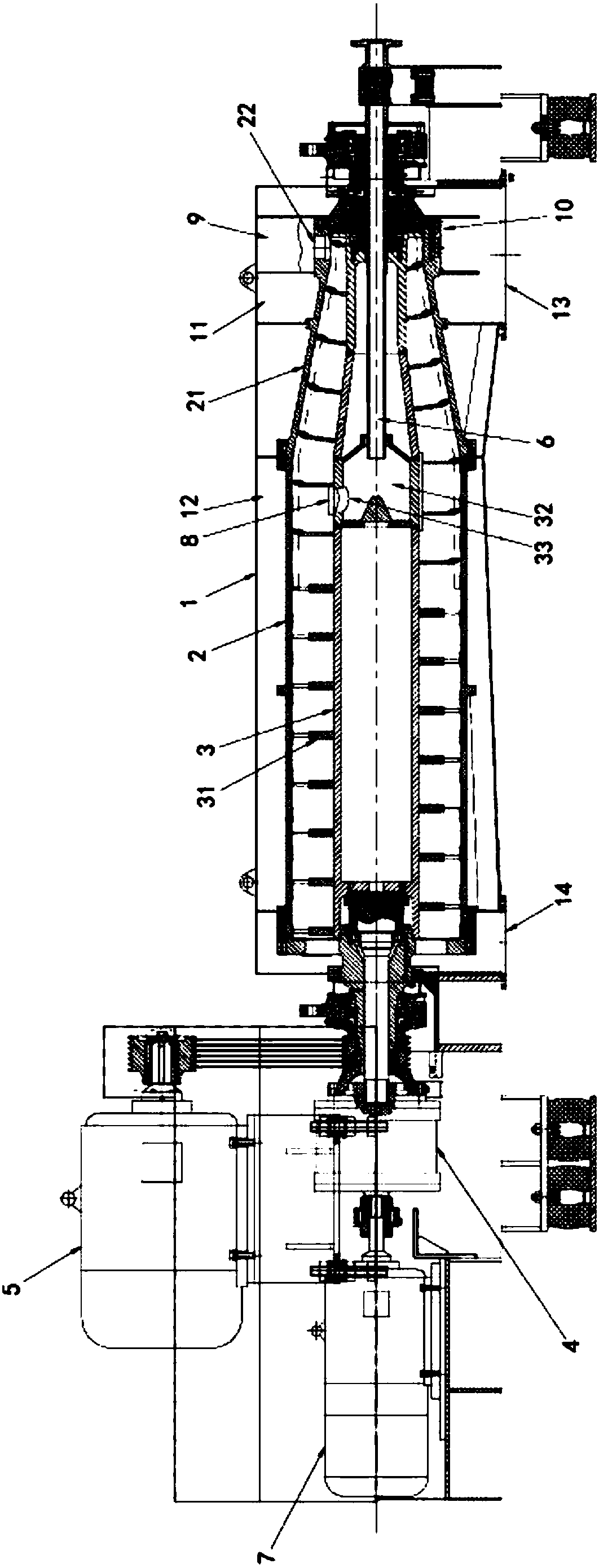

[0027] like figure 2 As shown, the distiller's grain waste liquid centrifuge in this embodiment includes a machine cover 1, a drum 2, a screw 3, a differential 4, a main motor 5, a feed pipe 6 and an auxiliary motor 7;

[0028] The hood 1 is cylindrical, the drum 2 is located in the hood 1, the screw 3 is located in the drum 2, the screw 3 is concentric with the drum 2, and the outer surface of the screw 3 is provided with a helical blade 31;

[0029] The main motor 5 drives the differential gear to drive the drum 2 to rotate, and the drum 2 and the screw 3 are connected through the differential gear 4; the differential speed between the drum 2 and the screw 3 is realized.

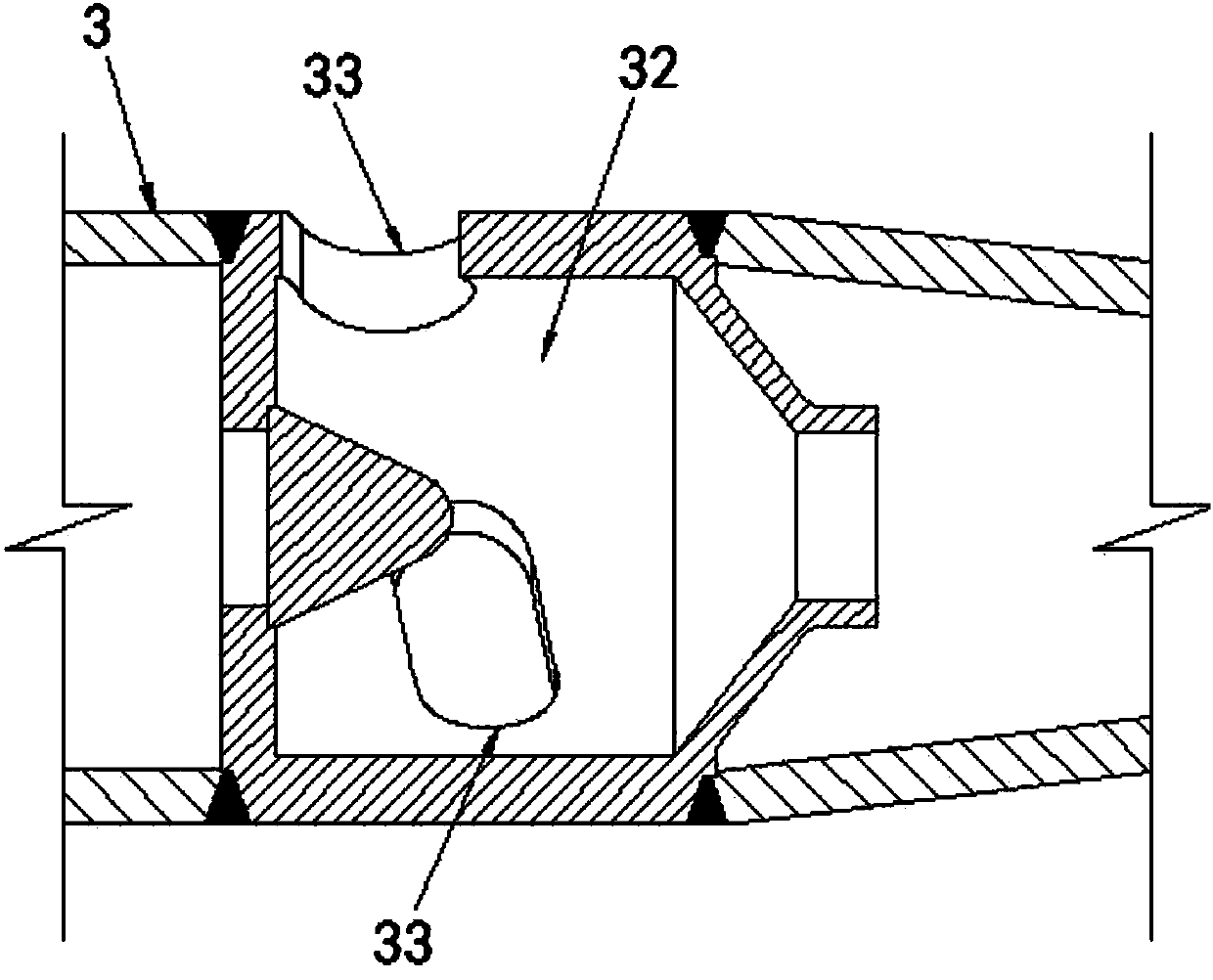

[0030] The interior of the spiral 3 is provided with a material chamber 32, and the nozzle of the feed pipe 6 extends into the material chamber 32; as image 3 As shown, the wall surface of the material chamber 32 is provided with a discharge port 33, the discharge port 33 is oblong, the discharge port 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com