Coating machine specially used for waterproof zipper coating layer

A technology of waterproof zipper and coating machine, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., which can solve the problems of large occupied area, inconvenient maintenance, high equipment height, etc., to reduce the occupied area Floor area, convenient maintenance work, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

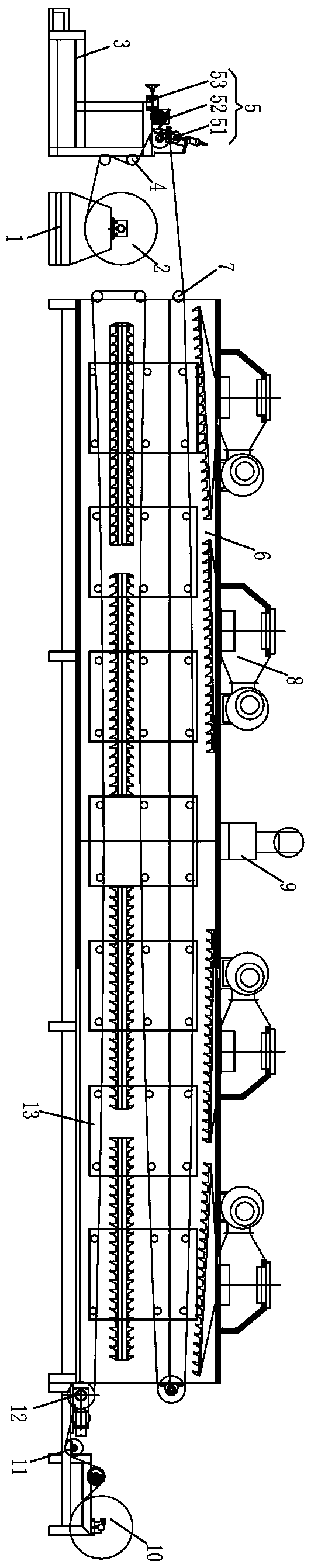

[0016] refer to figure 1 , a special coating machine for waterproof zipper coating, including a discharge workbench 1, a discharge wheel 2, a coating head platform 3, a material passing wheel 4, a coating mechanism 5, a coating wheel set 51, and a glue plate 52 , feeding hand wheel 53, hot air box 6, guide roller 7, hot air blower 8, exhaust gas discharge channel 9, receiving wheel 10, water cooling wheel 11, extrusion wheel 12 and hinged detection door 13, the discharge workbench The upper part of 1 is equipped with a discharge wheel 2, and the front side of the discharge workbench 1 is also equipped with a coating head platform 3, and the front side of the coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com