Boring head for machining cylinder tube of hydraulic cylinder

A technology of hydraulic cylinders and cylinders, applied in boring heads, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reduced production efficiency, increased production costs, low service life, etc., to extend service life and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

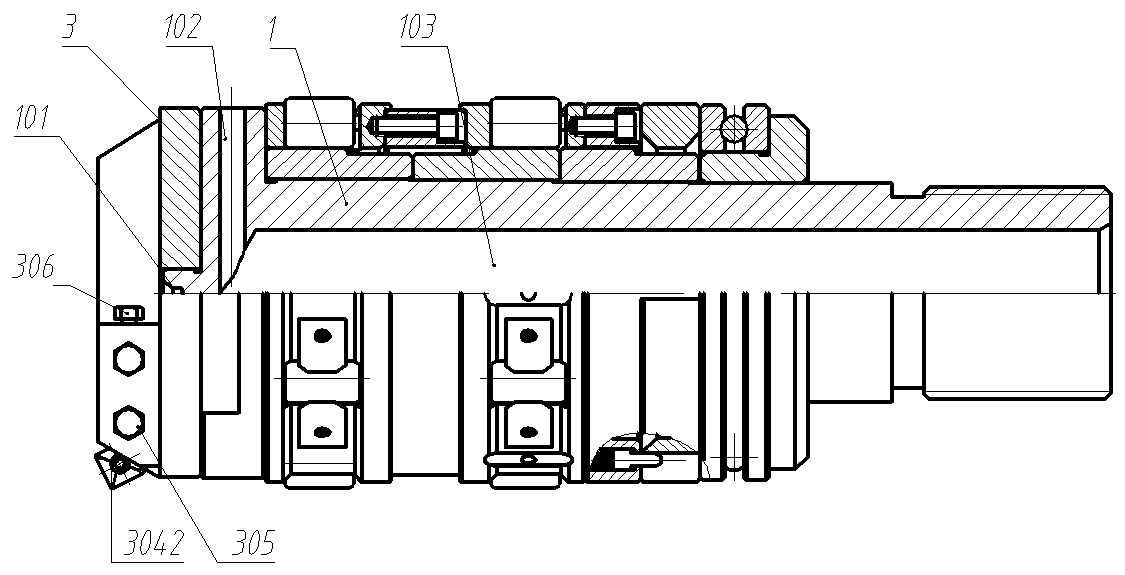

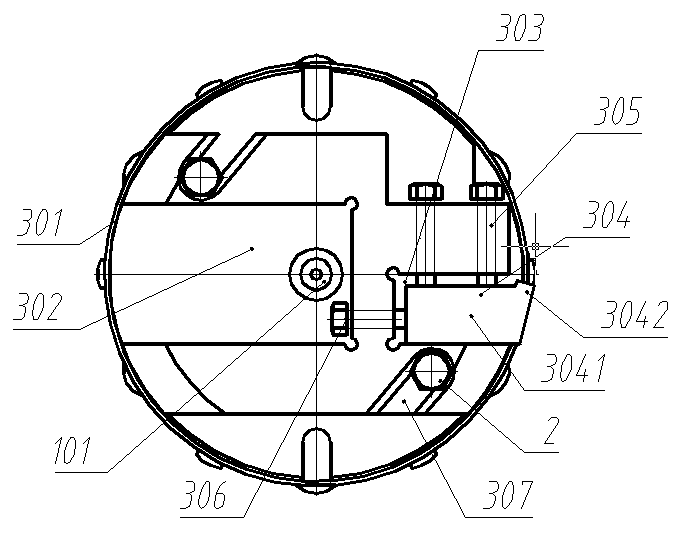

[0014] Such as Figure 1 to Figure 2 As shown, a boring head for machining hydraulic cylinder barrels includes a hollow mandrel 1 driven by a geared motor and a cutter head 3 mounted on the hollow mandrel 1 through connecting bolts 2 . The cutter head 3 is moved by the movement of the hollow mandrel 1 .

[0015] One end of the hollow mandrel 1 is closed, and the other end is open.

[0016] The cutter head 3 includes a disc body 301, one side of the disc body 301 is provided with a groove 302, and the other side is provided with a locking groove 303, and the middle part of the groove 302 is provided with a limiting through hole that runs through the disc body 301. The limiting through hole is matched with the limiting shaft 101 arranged at the closed end of the hollow mandrel 1 .

[0017] A cutting knife 304 is arranged in the slot 303, and a knife handle 3041 of the cutting knife 304 is fixed in the slot 303 by a fastening bolt 305. The cutter head 3042 of the cutting knife ...

Embodiment 2

[0027] Such as Figure 1 to Figure 2 As shown, a boring head for machining hydraulic cylinder barrels includes a hollow mandrel 1 driven by a geared motor and a cutter head 3 mounted on the hollow mandrel 1 through connecting bolts 2 . The cutter head 3 is moved by the movement of the hollow mandrel 1 .

[0028] One end of the hollow mandrel 1 is closed, and the other end is open.

[0029] The cutter head 3 includes a disc body 301, one side of the disc body 301 is provided with a groove 302, the groove 302 is cylindrical, and the other side is provided with a card slot 303, and the middle part of the groove 302 is provided with a through disk The limiting through hole provided on the body 301 is matched with the limiting shaft 101 arranged at the closed end of the hollow mandrel 1 .

[0030] A cutting knife 304 is arranged in the slot 303, and a knife handle 3041 of the cutting knife 304 is fixed in the slot 303 by a fastening bolt 305. The cutter head 3042 of the cutting k...

Embodiment 3

[0040] Such as Figure 1 to Figure 2 As shown, a boring head for machining hydraulic cylinder barrels includes a hollow mandrel 1 driven by a geared motor and a cutter head 3 mounted on the hollow mandrel 1 through connecting bolts 2 . The cutter head 3 is moved by the movement of the hollow mandrel 1 .

[0041] One end of the hollow mandrel 1 is closed, and the other end is open.

[0042] The cutter head 3 includes a disc body 301, one side of the disc body 301 is provided with a groove 302, and the other side is provided with a locking groove 303, and the middle part of the groove 302 is provided with a limiting through hole that runs through the disc body 301. The limiting through hole is matched with the limiting shaft 101 arranged at the closed end of the hollow mandrel 1 .

[0043] A cutting knife 304 is arranged in the slot 303, and a knife handle 3041 of the cutting knife 304 is fixed in the slot 303 by a fastening bolt 305. The cutter head 3042 of the cutting knife ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com