Instantly-dissolved-regular-colored-particle composition for solid detergent

A technology of solid detergent and colored particles, which is applied in the direction of detergent composition, organic detergent composition, detergent composition dye, etc., which can solve the problem of poor solubility and regular shape, high solubility and rough surface and other problems, to achieve good cold water solubility, improve visual aesthetics, and improve the effect of decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

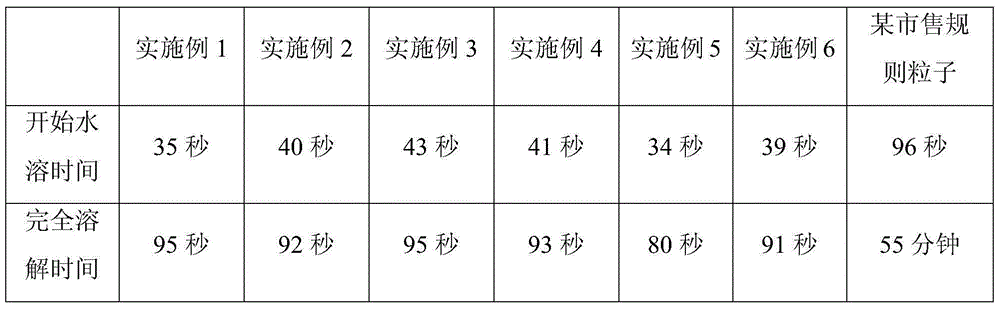

Embodiment 1

[0038] An instant regular colored particle composition for solid detergent, which is prepared by mixing the following raw materials according to the weight ratio, wherein: 6 parts of polyvinyl alcohol, 1 part of corn starch, 1 part of sodium citrate, 6 parts of glycerin, 0.5 part of sodium fatty alcohol polyoxyethylene ether sulfate, 1 part of sodium carboxymethyl cellulose, 1 part of ethanol, 0.2 part of pigment, 60 parts of process water.

[0039] The preparation steps are as follows:

[0040] a. Stirring: Add process water and sodium citrate into the stirring pot, stir to dissolve; add polyvinyl alcohol and cornstarch while stirring and heat up to 85-95°C to dissolve; add glycerin, fatty alcohol polyoxyethylene ether Sodium sulfate and sodium carboxymethyl cellulose are stirred and dissolved; when the temperature drops to about 60°C, add ethanol and pigment, and stir for 2-3 minutes to obtain glue;

[0041] b. Molding: the glue liquid is injected into the molding machine t...

Embodiment 2

[0046] An instant regular colored particle composition for solid detergent, which is prepared by mixing the following raw materials according to the weight ratio, wherein: 8 parts of polyvinyl alcohol, 1 part of wheat starch, 1 part of sodium citrate, 7 parts of glycerin, fat 0.2 parts of alcohol polyoxyethylene ether, 1.5 parts of sodium carboxymethyl cellulose, 1 part of ethanol, 0.2 parts of pigment, and 70 parts of process water.

[0047] The preparation steps are as follows:

[0048] a. Stirring: Add process water and sodium citrate into the stirring pot, stir to dissolve; add polyvinyl alcohol and cornstarch while stirring and heat up to 85-95°C to dissolve; add glycerin, fatty alcohol polyoxyethylene ether and sodium carboxymethyl cellulose, stirring and dissolving; when the temperature drops to about 60°C, add ethanol and pigment, and stir for 2-3 minutes to obtain glue;

[0049] b. Molding: The glue liquid is injected into the molding machine to form particles of the...

Embodiment 3

[0054]An instant regular colored particle for solid detergent, which is made by mixing the following raw materials according to the weight ratio, wherein: 10 parts of polyvinyl alcohol, 1 part of wheat starch, 1.5 parts of sodium citrate, 8 parts of glycerin, fatty alcohol poly 0.5 parts of sodium oxyethylene ether sulfate, 1.5 parts of sodium carboxymethyl cellulose, 1.5 parts of ethanol, 0.2 parts of pigment, and 70 parts of process water.

[0055] The preparation steps are as follows:

[0056] a. Stirring: Add process water and sodium citrate into the stirring pot, stir to dissolve; add polyvinyl alcohol and cornstarch while stirring and heat up to 85-95°C to dissolve; add glycerin, fatty alcohol polyoxyethylene ether Sodium sulfate and sodium carboxymethyl cellulose are stirred and dissolved; when the temperature drops to about 60°C, add ethanol and pigment, and stir for 2-3 minutes to obtain glue;

[0057] b. Molding: the glue liquid is injected into the molding machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com